Unleash the Power of 3D Printing

V1 offers a full suite of advanced 3D printing technologies to turn your designs into high-quality parts with speed and precision.

Harness the Full Potential of 3D Printing with V1

At V1, we offer a complete range of 3D printing services to promptly translate your ideas into top-notch final parts. We provide state-of-the-art 3D printing capabilities, including FDM for robust and long-lasting prototypes and production parts, SLA for sleek and detailed resin models, SLS for highly accurate and intricate geometries, MJF for exceptional mechanical properties perfectly suited for end-use parts and SLM for elaborate metal components. With speedy quotations, professional guidance and prompt turnaround times, we unlock the maximum potential of 3D printing to hasten your product development and advance manufacturing agility. Collaborate with us and utilise our comprehensive 3D printing solutions to maintain competitiveness and expedite your inventions to market.

3d printing technologies

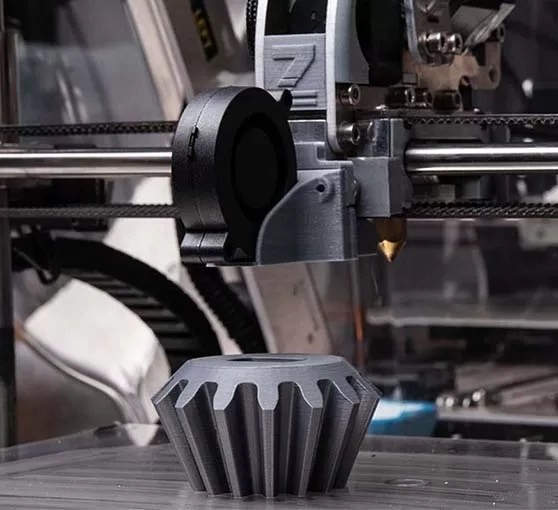

FDM 3D Printing

FDM 3D Printing is an additive manufacturing process that builds parts layer by layer using melted material. It uses a heated nozzle to deposit thermoplastic filament, creating each layer. FDM is well-suited for rapid prototyping and low-volume production, offering a quick turnaround time with parts printed in just 1 day. It provides a range of robust industrial-grade materials, such as ABS and nylon, for creating high-strength and durable prototypes and end-use parts. FDM ensures accurate and reliable parts while remaining cost-effective.

3d printing technologies

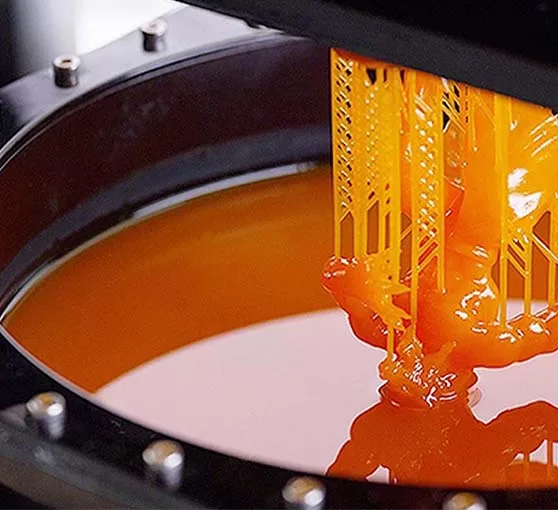

SLA 3D Printing

Stereolithography (SLA) is a versatile 3D printing technology known for its speed and accuracy. It uses a UV laser to cure liquid resin layer by layer, creating detailed parts. SLA offers fast turnaround times, a wide range of resin options, smooth surface finishes, and precise dimensions. It excels in printing complex designs and offers post-processing choices like dyeing and polishing. SLA generates minimal waste, making it environmentally friendly. It's suitable for prototyping and medium-volume production in various industries such as motorsports, dental, medical, and aerospace.

3d printing technologies

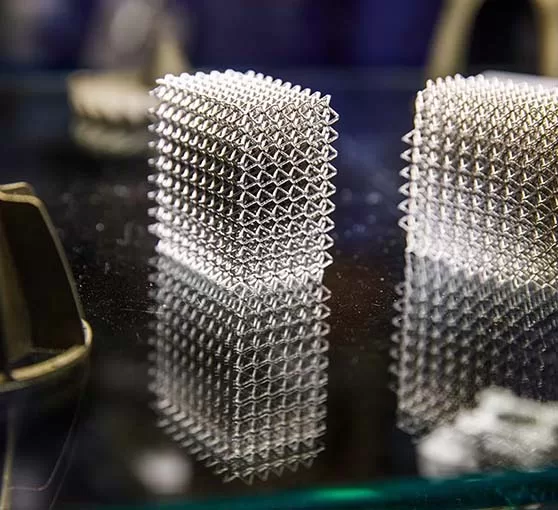

SLS 3D Printing

SLS is a powder-based 3D printing process for functional prototyping and short-run production. It fuses fine powder material using a laser to create strong parts. Key advantages include fast build speed (3-5 days), excellent mechanical properties, complex geometries (lattice structures, voids), no need for support structures, various finishing options, low waste (reusable powder), scalability, and applications in automotive, aerospace, and consumer industries.

3d printing technologies

MJF 3D Printing

Multi Jet Fusion (MJF) is an industrial 3D printing process used for rapid prototyping and production. It offers fast build speed (3-5 days), excellent mechanical properties, and a wide range of production-grade materials. MJF allows for complex geometries without supports, delivers smooth surface finishes, and requires minimal post-processing. It generates low waste with reusable excess powder. MJF is scalable for both prototyping and medium-volume production and finds applications in various industries such as automotive, medical, and consumer goods.

3d printing technologies

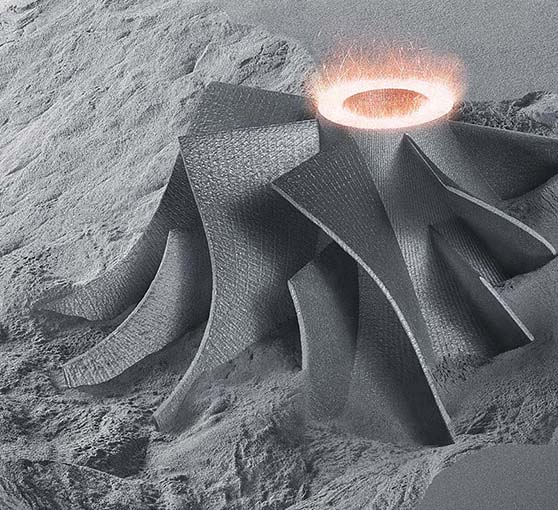

SLM 3D Printing

SLM is a fast metal 3D printing process that produces complex, high-performance parts with excellent mechanical properties. It uses a wide range of metals such as aluminum, titanium, stainless steel, and alloys with little waste. The process is scalable for prototyping to mid-volume production measuring small features down to .004” (.1mm). It is a perfect fit for manufacturing precision parts in aerospace, automotive, and medical fields.