Discover Custom Components for Health Innovations

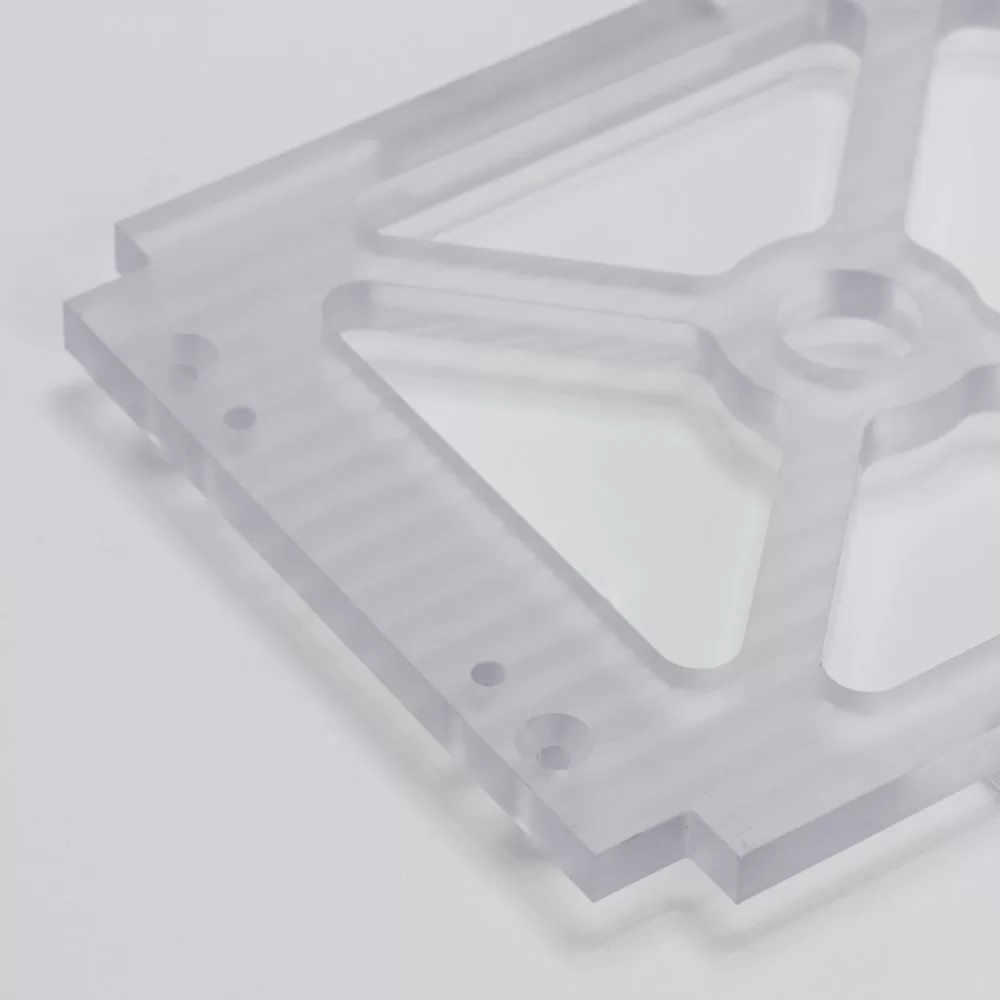

Elevate your health innovations with our bespoke components. Experience intricate designs and stylish finishes that combine form and function seamlessly.

Develop equipment that improves patient care

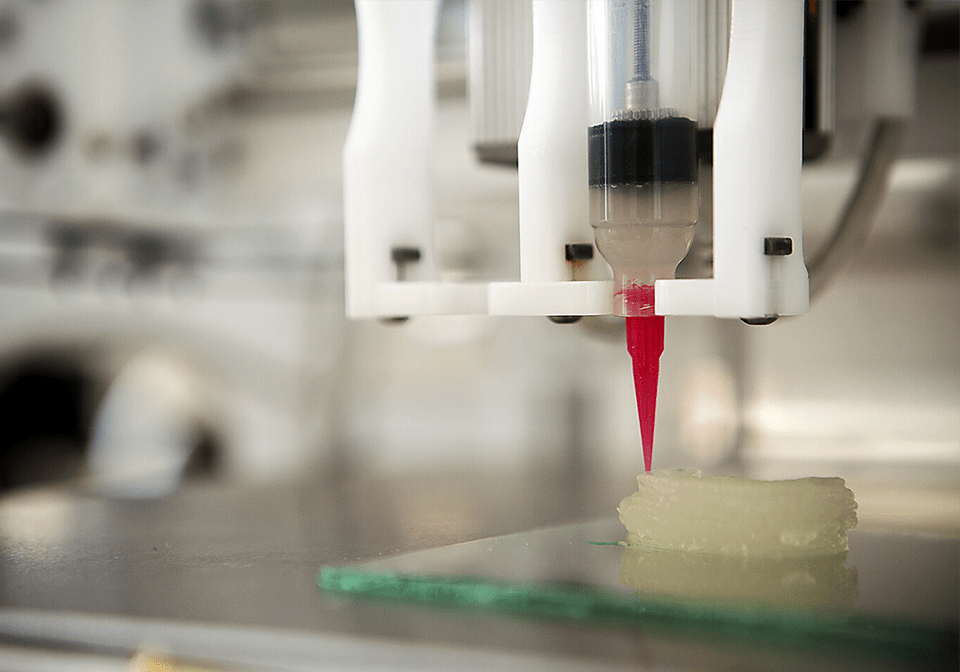

V1 is the perfect solution for producing bespoke components for diagnostic and medical devices. Our immediate quoting platform speeds up product development, allowing quicker prototyping, innovation, and a greater impact on people's lives. Our extensive manufacturing network can produce vast quantities of innovative biotech, medical imaging, and stem cell equipment, including jigs and fixtures to support them.

Certified for every application

V1 is ISO 9001 certified and our suppliers hold industry certifications.

- ISO 9001

- ISO 13485

- ISO 14001

- ISO 9100

- ISO TS16949

Comprehensive documentation of quality standards

Obtain validation reports for maximum quality and adherence to regulations.

- CMM Inspection Record

- Complete dimensional inspections

- Reports on Material Tests

- Certificates of Material

- Certificates of Compliance

- Initial inspections of articles

Extensive capabilities

Access a wide range of technologies to manufacture custom parts, including those for medical equipment.

- CNC machining (including 3-axis and 5-axis), milling and turning

- Injection moulding

- ABS M30i and Ultem 1010 are used for FDM and SLA 3D printing.

- Over 50 types of metals and plastics are available.

- Options are available for functional & cosmetic post-processing.

Local manufacturing with 5 day lead times

Have your CNC parts manufactured locally. For customers in the US and EU, we offer a choice of local or global manufacturing options so you can get your parts faster. This means manufacturing can take place within your customs zones, so you benefit from fewer logistical hurdles and faster delivery times.

How medical parts manufacturers use V1

- Med-tech prototypes

- Electronic medical devices

- Surgical tooling

- Anatomical models

- Prosthetics

- Implants

- Pharmaceutical equipment

- Dental equipment

- Jigs & fixtures

- Casings

Medical manufacturing capabilities

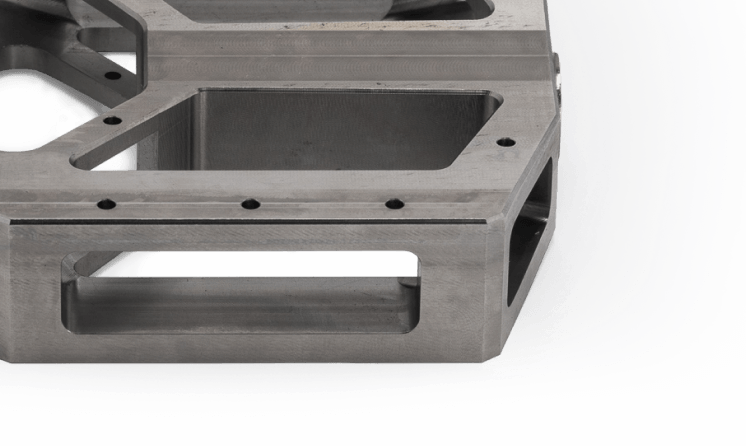

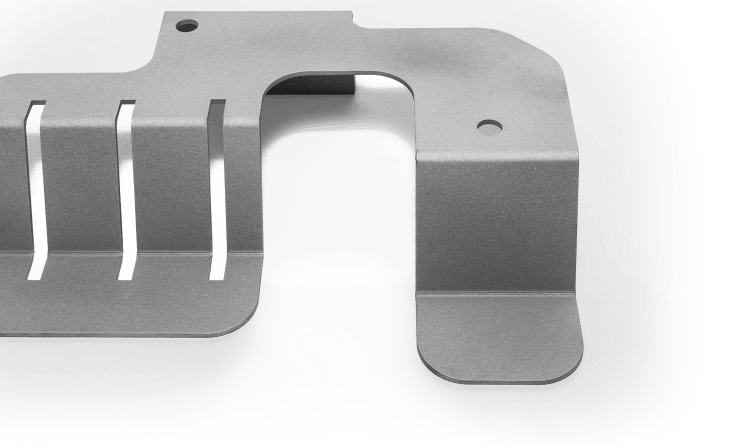

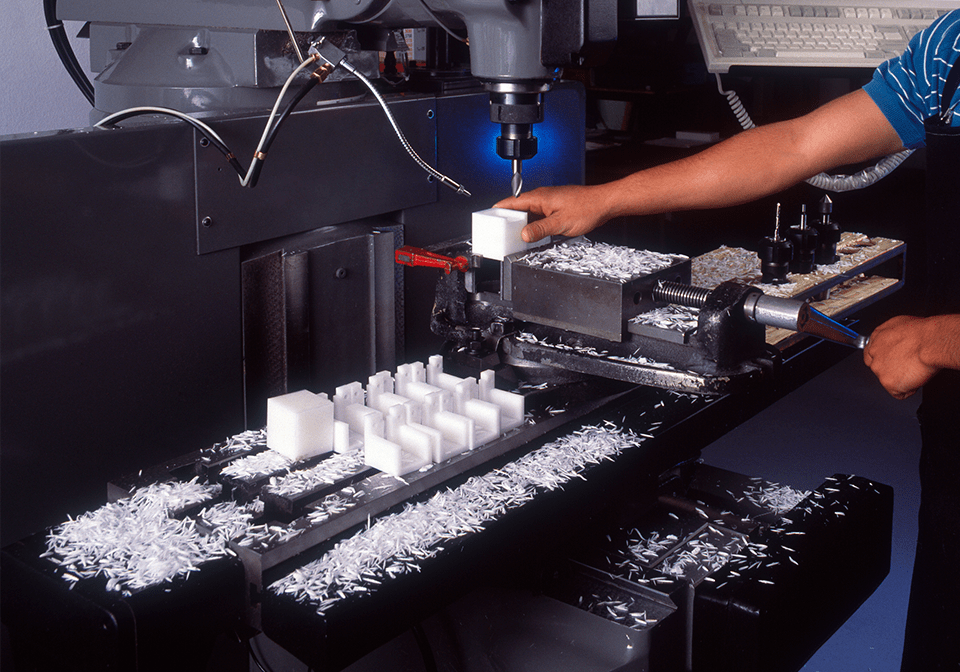

CNC milling

For cost-efficient prototypes and production

- 3-, 4- & 5-axis milling

- Lead times from 5 business days

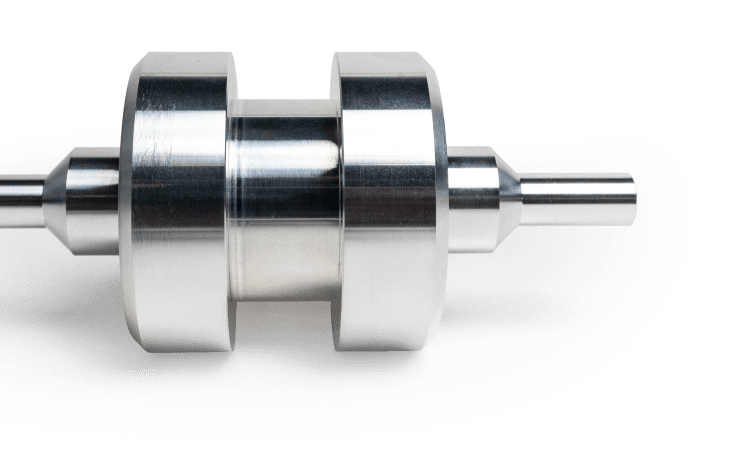

CNC turning

Lathes and live tooling ideal for cylindrical parts

- 60+ metals & plastics, including 10+ aluminum & 20+ steel

- Lead times from 5 business days

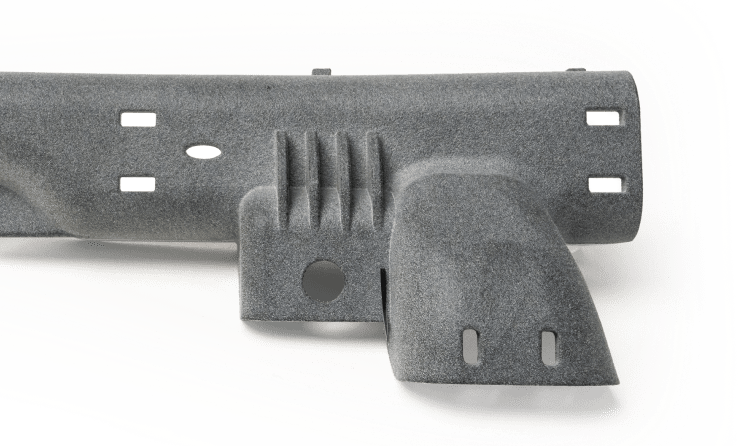

3D printing

FDM, SLA, SLS, MJF,SLM

- 25+ plastics & 35+ colors

±0.5% dimensional accuracy with a lower limit down to ±0.0059 in (0.15 mm) - Lead times from 1 business day

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Why healthcare engineers use V1

Specialized network

Get access to cutting-edge capabilities and limitless capacity

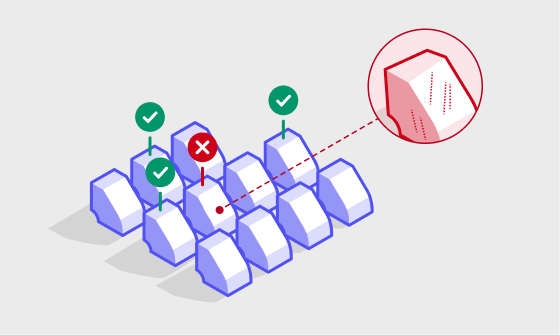

Quality assurance

Our ISO 9001-certified quality management system ensures reliable quality across our network.

Instant pricing

Get instant quotes with all pricing information upfront

Materials and surface finishes for medical components

We offer access to a vast array of robust materials through our trusted manufacturing partner network.

Materials for medical devices

Choose from over 30 metallic alloys and hundreds of industrial-grade plastics.

Steel and stainless steel options: 304/304L, 316/316L, 17-4H

Titanium options: Titanium grades 1, 2, and 5

Aluminium: 6061-T6, 7075-T6, 5083-H111, and 2024-T351

Brass and copper alloys: C360 brass, copper C110, and copper C101

Thermoplastics are commonly used in different applications: for example, Polycarbonate (PC), ABS M30i, PLA, PEEK, Ultem 1010, and PA 12

Commodity polymers are also used in various sectors. We offer polyethylene (PE), polypropylene (PP), and PVC materials.

Surface finishes for medical devices

Improve durability and performance with a selection of finishes

Anodizing

Polishing

Brushing + Electropolishing

Smooth machining

Electroless nickel plating

Chromate Conversion Coating

Sandblasting/Shot Peening

Part marking/Laser engraving

Gallery of medical parts

How V1 helps medical companies innovate

Competitive pricing, IP protection and DFM guidance

The V1 platform provides the simplest solution for comparing prices for order volumes, lead times, materials, tolerances, secondary processes, and more for your projects. Receive upfront all final pricing information, including shipping, quality control, and customs clearance (when ordering from the US and EU). We prioritize IP protection on the platform and throughout the process to ensure the complete security of your designs and models. Our platform is equipped with design for manufacturability (DFM) analysis, and our mechanical engineers are always ready to offer guidance to help you derive maximum benefits from V1.

On-time delivery and precise adherence to specifications

We maintain a stable and robust supply chain by strictly adhering to thorough quality control processes and protocols. Before joining the network, our manufacturing partners undergo a complete vetting process. Our on-site quality engineers conduct frequent audits to ensure that they meet the V1 Standard. Our internal teams in Amsterdam and Chicago inspect parts for functionality and cosmetic specifications. We also handle all custom clearance requirements and ensure on-time delivery.

Minimize supply chain risks with local and global sourcing

Supply chain resilience is crucial, particularly when you require parts on a tight schedule and with specific certifications. We provide local and global sourcing to mitigate your supply chain risks and offer sourcing solutions that comply with your requirements. V1 offers access to a comprehensive network of industrial 3D printing, CNC machining, injection molding, and sheet metal experts with reliable capacity for your aerospace and aviation projects, regardless of the project's scale.

FAQ's

We conduct comprehensive checks of each manufacturing partner (MP) during the onboarding process and carry out audits of their processes and certifications every two years. To procure parts from certified manufacturers, you may specify the requirements on the platform or get in touch with us at 3dprinting@v-1.com. We will match your designs with the most appropriate supplier.

Our platform guarantees the security and encryption of all customer data and supplier interactions. Digital models and drawings are safely stored on European-based AWS servers. Our Manufacturing Partner Agreement is mandatory for MPs to sign as part of their onboarding process, committing them to the confidentiality of customer data. Our General Terms of Sale prohibit orders which infringe on copyrights, patents, design rights, trademarks, trade secrets, or any other type of intellectual property rights.

Engineers use V1 partly because we assume all the risks on your behalf. In case your parts do not meet the required specifications, you may file a dispute claim and we will either remake the components or refund your order. For further details on how we manage disputes, please contact our Customer Success Team. At the same time, we generate non-conformity reports for parts that fail to meet all requirements and offer follow-up with manufacturers, including root cause analysis and rapid corrective actions.

To obtain parts made from specialized materials that are not included on our site or platform, you may submit a request to your account manager or contact us at 3dprinting@v-1.com. Our supplier network has access to a vast range of materials, enabling us to find a manufacturing partner to fulfill most of your requests.