MJF 3D Printing Service

Obtain 3D printed parts using our advanced Multi Jet Fusion (MJF) capabilities. We offer functional prototyping services and full-scale production capacity with a range of high quality finishing options. Lead times from 3 days.

What is Multi Jet Fusion?

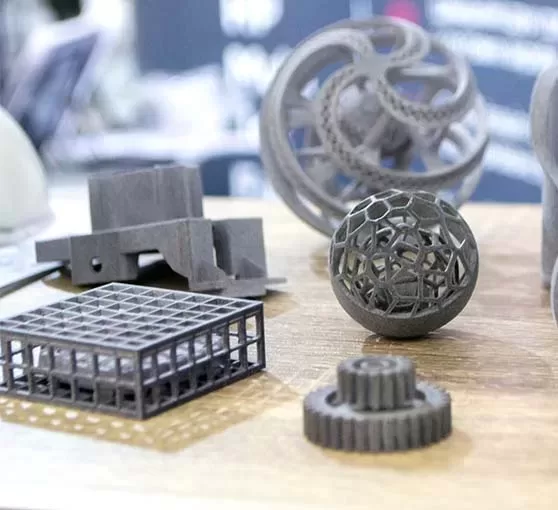

Multi Jet Fusion (MJF) is an advanced 3D printing process that can rapidly produce accurate, complex and detailed parts from powdered thermoplastics. MJF parts have high strength and fine feature resolution, making them ideal for complex industrial parts. Developed by HP, this relatively new 3D printing technology is ideal for producing functional prototyping and production parts with isotropic mechanical properties, making it ideal for any application requiring geometric complexity and impressive cosmetic and mechanical properties.

MJF (Multi Jet Fusion) capabilities

| Maximum build size | Standard lead time | Dimensional accuracy | Layer height | Minimum feature size |

|---|---|---|---|---|

| 380 × 284 × 380 mm | From 3 business days | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012 in) | 80μm | 0.5 mm |

MJF 3D Printing uses strong, versatile materials

Leading companies in many industries turn to MJF for its industrial-grade materials.

| Material | Color | Resolution | Tensile strength | Elongation at break | Heat deflection temperature | Application |

|---|---|---|---|---|---|---|

| HP PA 12 (Nylon 12) | Gray, dyed black | 80μm | 48 MPa | 15-20 % | 95-175 °C | Functional prototypes, complex assemblies, watertight applications |

| Glass-filled HP PA 12 (US only) | Gray | 80μm | 30 MPa | 6.5 % | 121-173 °C | Enclosures, housings, cases, fixtures, structural parts, tooling |

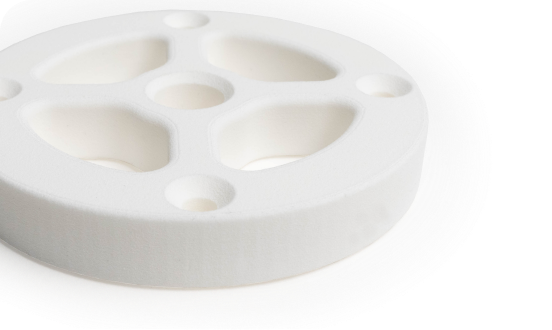

Surface finishes for MJF 3D printing

One of the benefits of MJF 3D printing is the quality of the part surfaces, especially after finishing. Here are the surface finishes available for MJF.

As printed (grey)

Grey colour, smooth surface, no visible layers, powder texture

Dyed (Black)

Dyed black by immersion in a warm dye bath. The colour penetrates to a depth of approximately 0.5mm on all surfaces.

Tumble polishing

Parts are placed in a tumbler of ceramic chips to give a polished finish similar to injection moulding.

How MJF compares to other 3D printing technologies

| Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|

| FDM | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787'') |

| Industrial FDM | ± 0.25% with a lower limit: ± 0.25 mm (± 0.010") | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787'') |

| Prototyping SLA | ± 0.5% with a lower limit of ± 0.15 mm (± 0.006") | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787'') |

| Industrial SLA | ± 0.2% with a lower limit of ± 0.127 mm (±0.005") | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787'') |

| SLS | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196”) |

| MJF | ± 0.3% with a lower limit on ± 0.3 mm (0.012'') | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9'' x 11.2'' x 14.9'') | 80μm | 0.5 mm (0.0196”) |

We have high standards for MJF 3D printing

We maintain rigorous standards for MJF 3D printing. Our avant-garde technology and proficient team guarantee exceptional quality and precision in each print. Rely on us for outstanding outcomes regarding prototype development and end-use components. Our unwavering devotion is to provide exceptional levels of quality and reliability.

Advantages and drawbacks of MJF 3D printing

Overall, MJF combines the speed advantage of FDM with the material advantage of SLS, which is particularly suitable for rapid printing of technical materials, but the equipment is expensive and there are still some application limitations.

Advantages

- Fast print speeds

- Excellent surface finish

- High-detail resolution

- Scalability for small-batch manufacturing

- Versatility in material options

Drawbacks

- Limited material selection

- Potential need for post-processing

- Higher cost compared to other technologies

- Size and build volume limitations

- Requirement for support structures

Design Guidelines for MJF

This table summarises the recommended and technically feasible values for the most common features of MJF 3D printed parts.

| Feature | Recommended size |

|---|---|

| Unsupported walls | 1.0 mm (0.040 in) |

| Supported walls | 0.7 mm (0.030 in) |

| Minimum detail size | 0.25 mm (0.010 in) |

| Minimum hole size | 1.0 mm (0.040 in) |

| Moving parts | 0.5 mm (0.020 in) |

| Assembly clearance | 0.4 mm (0.016 in) |

| Maximum wall thickness | 20 mm (0.8 in) |

Our other 3D printing processes

FDM

Fast & affordable prototyping

- Dimensional accuracy of ± 0.05% with a lower limit: ± 0.05 mm

- Lead times from 1 business day

SLA

Visual prototyping

Dimensional accuracy of ± 0.5% with a lower limit of ± 0.15 mm (± 0.006")

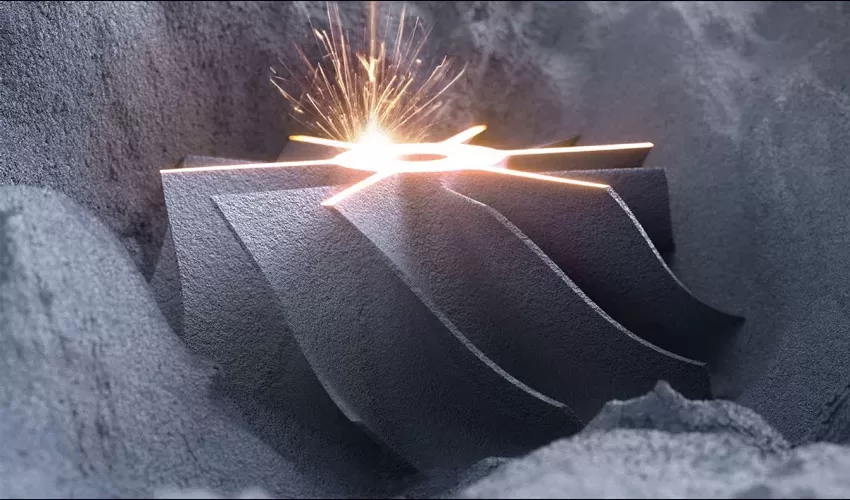

SLS

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.0118")

SLM

High-precision metal manufacturing

- Dimensional accuracy of ± 0.1% with a lower limit: ± 0.1 mm

- Suitable for complex and detailed metal parts

- Lead times from 2-3 business days