Sheet Metal Fabrication Service

Advantages of using V1 in sheet metal fabrication

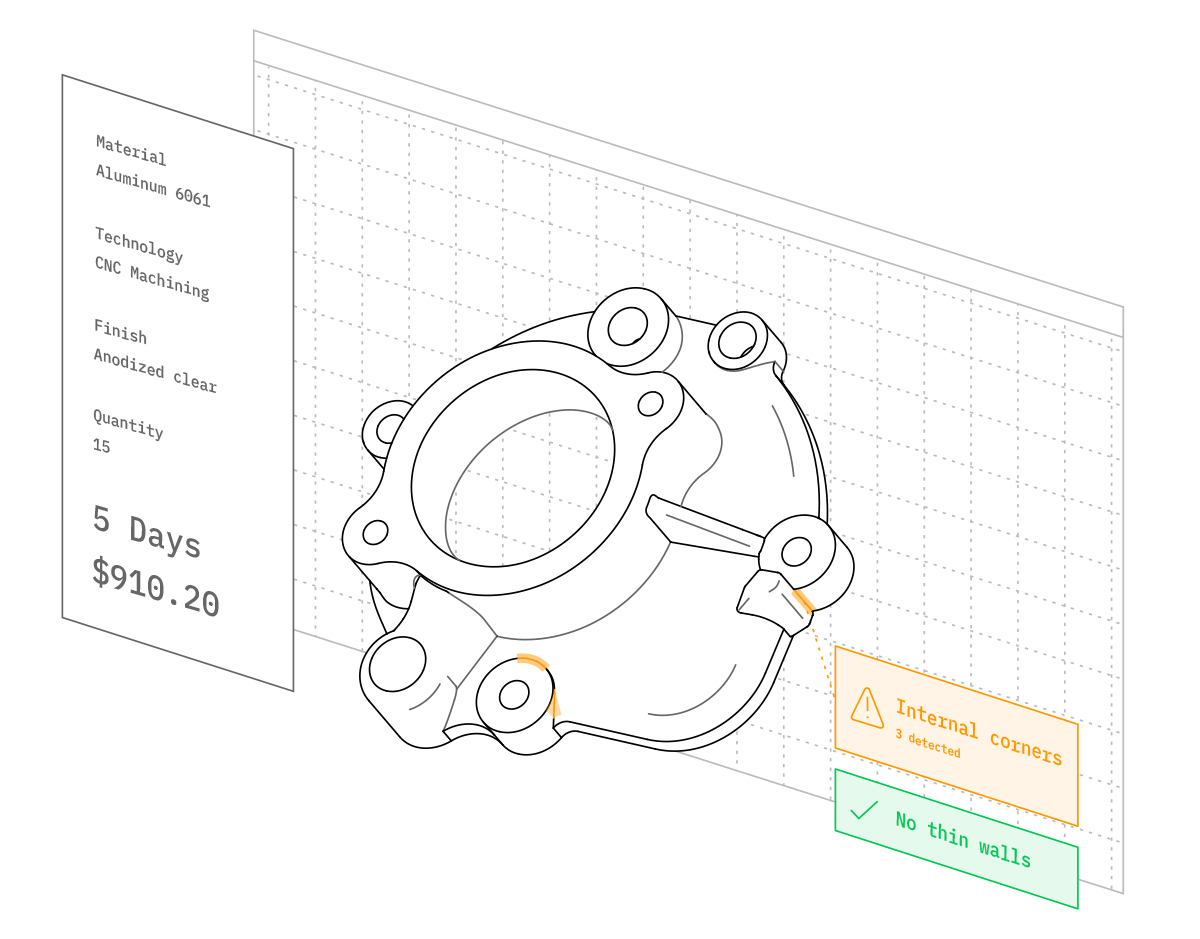

Instant quoting & DfM feedback

Create and modify your quote via the internet. Evaluate your components for suitability for manufacturing and calculate the expenses of various materials, procedures, and delivery times for your task instantly.

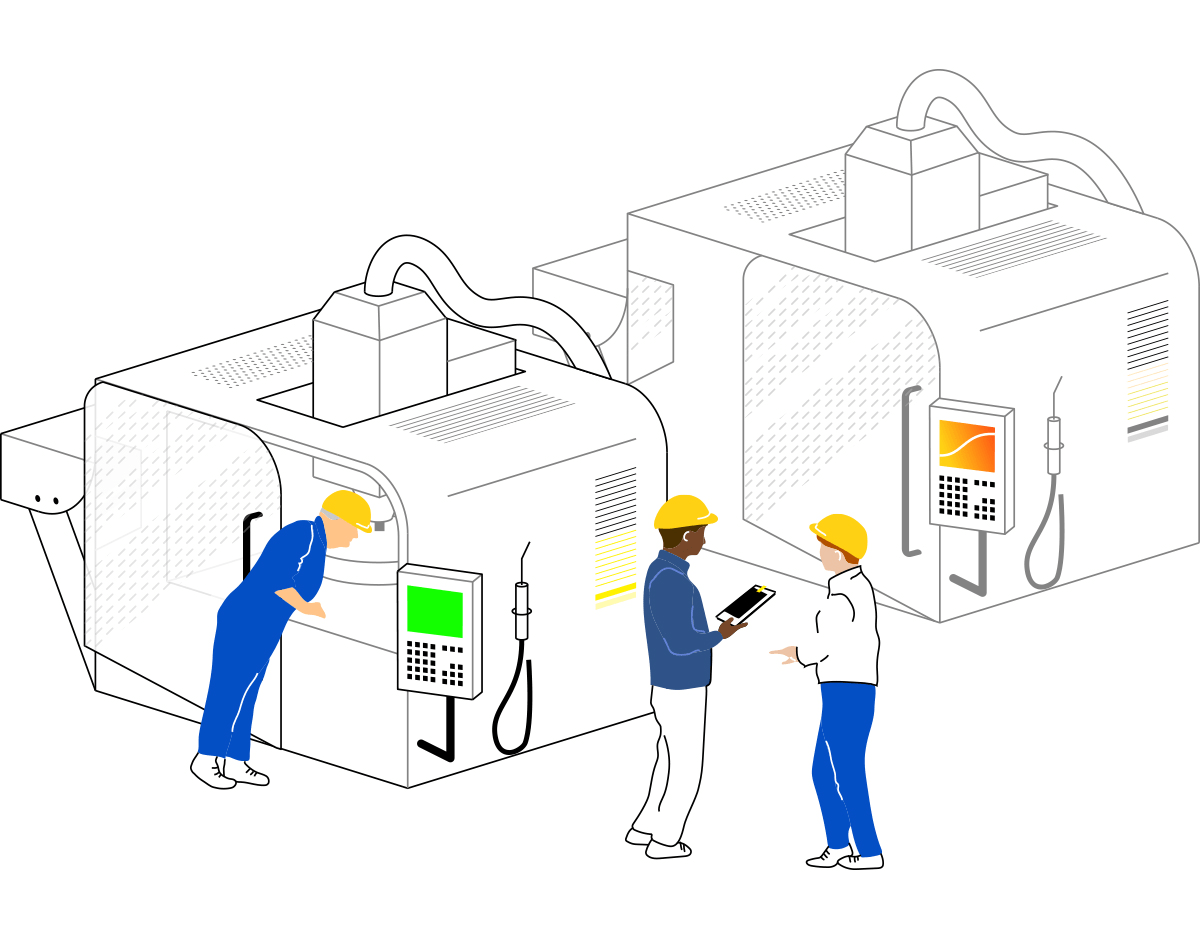

Readily available capacity

Leverage our network of 250 manufacturing partners to access readily available capacity instantly. Our manufacturing partners are located locally and overseas.

Quality and reliability

We have a dedicated V1 team to guarantee that your parts meet your quality expectations consistently. Additionally, we provide phone, email and chat support to address any concerns or questions you may have.

To receive a free quote, upload your designs.

What is the process of sheet metal fabrication?

The process of sheet metal fabrication involves cutting and bending metal sheets to create various shapes.

Fabricating sheet metal is more cost-effective than CNC machining while dealing with metal components with a uniform wall thickness.

Available materials for sheet metal

Our standard materials for sheet metal fabrication are: To request a custom material, please get in touch with 3dprinting@v-1.com.

| Aluminum | Stainless steel | Mild steel | Copper |

|---|---|---|---|

| 5052 | 304 | 1018 | C110 |

| 5754 | 316L |

Sheet metal fabrication processes currently available

Our network of manufacturing partners provides convenient access to sheet metal fabrication capabilities for all your manufacturing requirements.

| Name | Description | Allowable sheet thickness |

|---|---|---|

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 1-6mm (depending on material) |

| Bending | This manufacturing process uses dies to produce a U-shape, V-shape or channel shape along a straight axis in ductile materials. | 1-6mm (depending on material) |

Sheet Metal Fabrication Tolerances

The table below summarizes the standard tolerances of the parts produced by certified V1 Manufacturing Partners.

| Feature | Tolerance |

|---|---|

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010” (0.254mm) |

Learn more about our manufacturing services

Surface finishes available for sheet metal

Surface finishes are applied after machining and can alter the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

| Name | Description | |

|---|---|---|

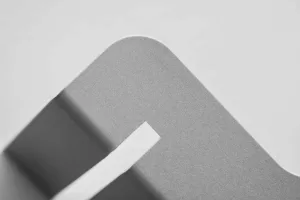

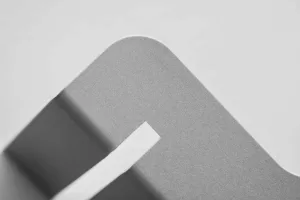

|

Standard | This is our standard surface. Parts are delivered cut and bent, without any further processing. Sharp edges are removed to ensure safe handling. |

|

Bead Blasted | Glass beads are used to bead blast parts, resulting in a grainy texture. Sharp edges are removed to ensure safe handling. |

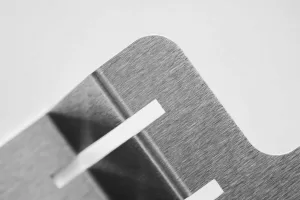

|

Brushed | After they are cut and bent, parts are manually brushed with grit #180. To ensure safe handling, sharp edges are broken and deburred. This is ideal for reducing the surface roughness of a part. |

|

Brused + Anodized type II | After manual brushing, the parts are dipped in an anodizing bath (type II). This process is useful in enhancing the corrosion resistance of the part. This process is useful in enhancing the corrosion resistance of the part. To ensure safe handling, sharp edges are smoothed and deburred. |

|

Bead blasted + Anodized type II | The components undergo an anodizing process (Type II) after being bead blasted. This process is useful in enhancing the corrosion resistance of the part. To ensure safe handling, sharp edges are smoothed and deburred. |

|

Anodized type III (Hardcoat) | Components dipped in an anodizing (Type III) solution immediately after fabrication. It is an ideal solution to enhance the corrosion and wear resistance of the components. To ensure safe handling, sharp edges are smoothed and deburred. |

|

Powder coated | The powder coating layer is applied immediately after fabrication. To ensure safe handling, sharp edges are smoothed and deburred. |

|

Black oxide | After fabrication, parts are treated with a black oxide bath. This process is ideal for enhancing corrosion resistance and reducing light reflection in steel components. To ensure safe handling, sharp edges are smoothed and deburred. |

|

Chromate conversion coating | After fabrication, the parts are immersed in an alodine bath. It is ideal to enhance the corrosion resistance of the part while retaining its conductivity. It complies with RoHS regulations. To ensure safe handling, sharp edges are smoothed and deburred. |

Our Other Manufacturing Capabilities

We offer a comprehensive range of manufacturing capabilities including 3D printing, CNC machining, injection molding and mold manufacturing to turn your vision into reality. Our experienced engineers identify the ideal production methods for your products to deliver maximum quality, value and speed.

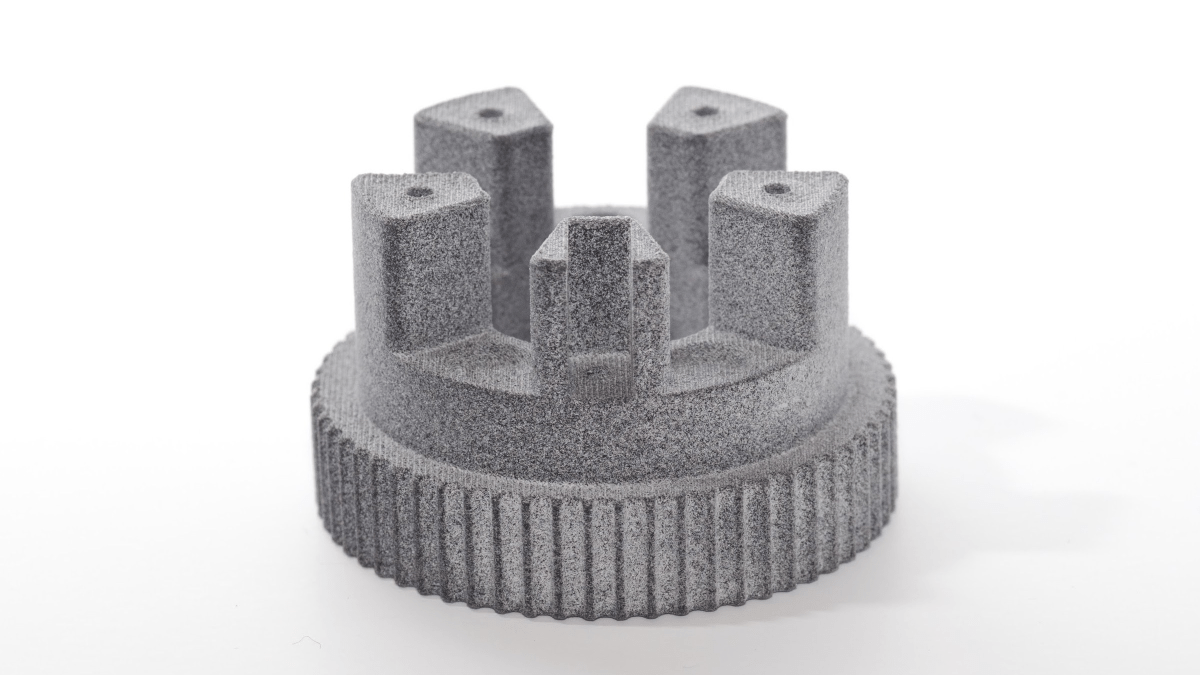

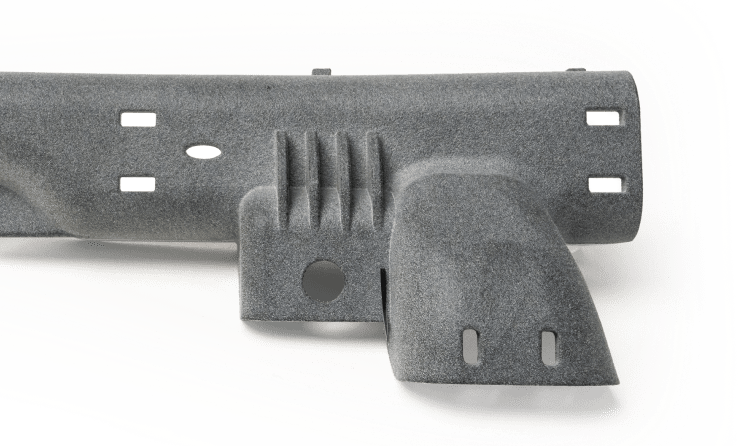

3D printing

FDM, SLA, SLS, MJF、SLM

- 25+ plastics & 35+ colors

±0.5% dimensional accuracy with a lower limit down to ±0.0059 in (0.15 mm)

- Lead times from 1 business day

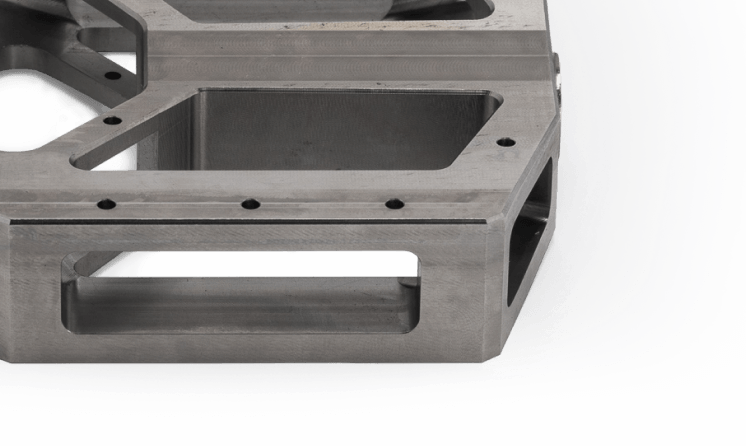

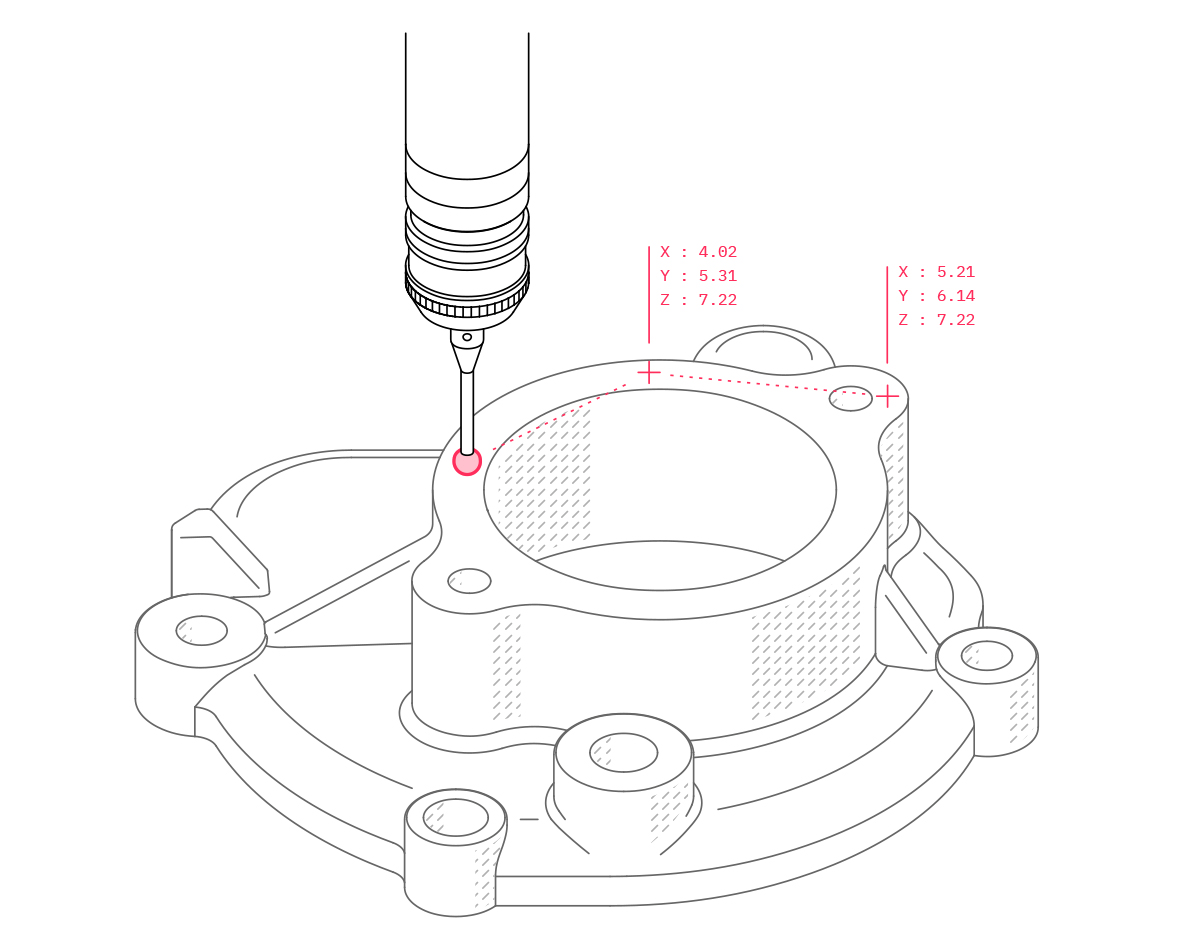

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

Mold Manufacturing

Precision CNC Machining, EDM, Post-Processing

- Tolerances down to ±0.005 mm

- Lead times from 5 business days

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M parts