Online 3D printing service

The easiest way to source high quality 3D printed prototypes and production parts. Order from our network of highly experienced 3D printers. ISO 9001, ISO 13485 and AS9100 certified.

Our 3D printing capabilities

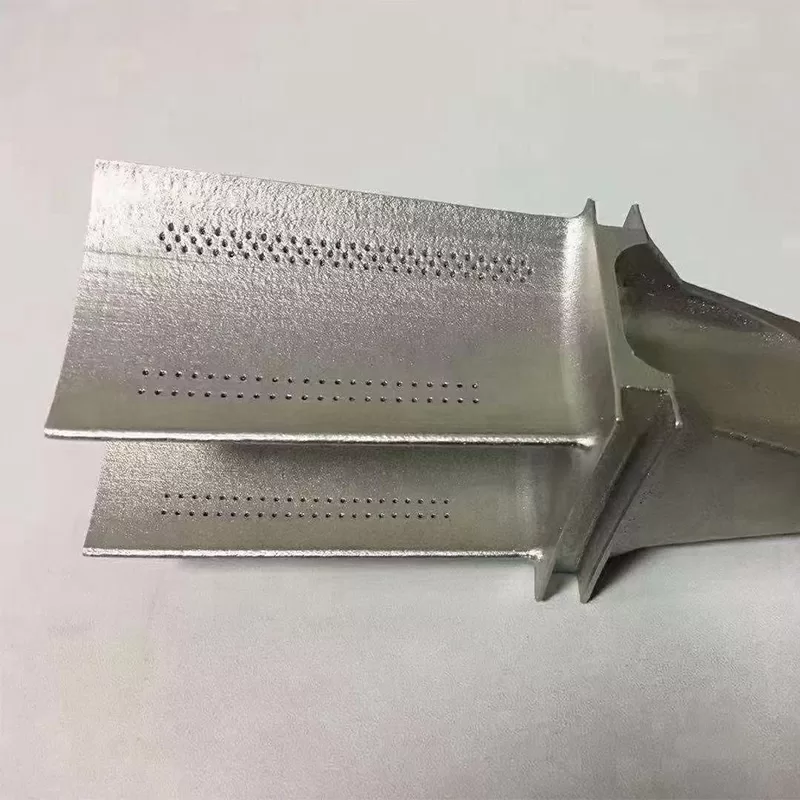

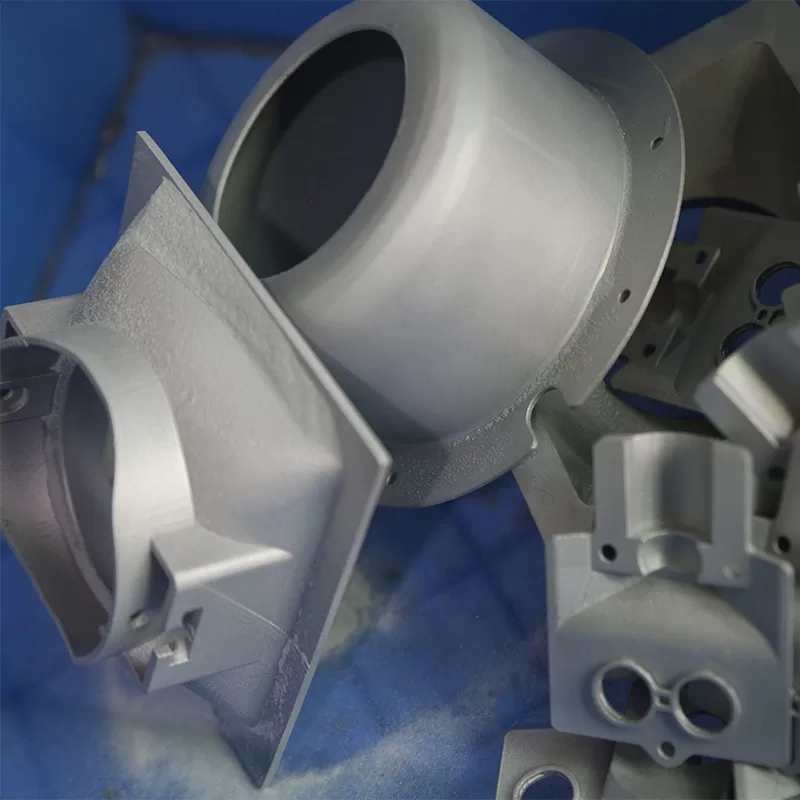

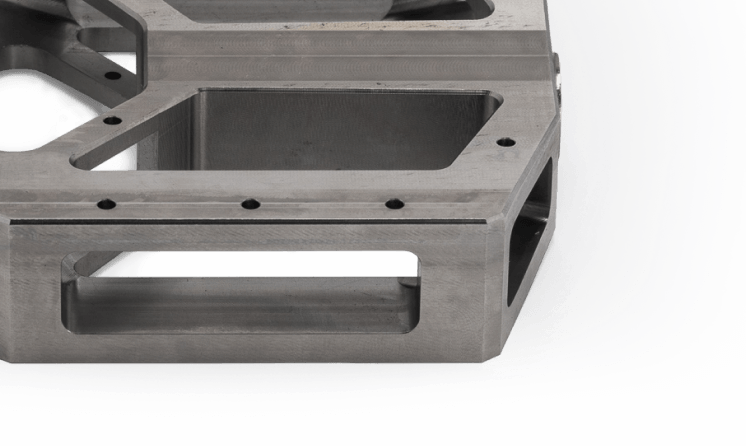

Metal 3D Printing

Metal 3D printing is an advanced technology for producing high-performance metal parts with complex geometries and exceptional precision. It caters to industries such as aerospace, automotive, medical, and industrial manufacturing. By offering rapid manufacturing cycles, flexibility, and customization, metal 3D printing services enable industrial users to reduce costs, enhance efficiency, and drive innovation.

Our 3D printing capabilities

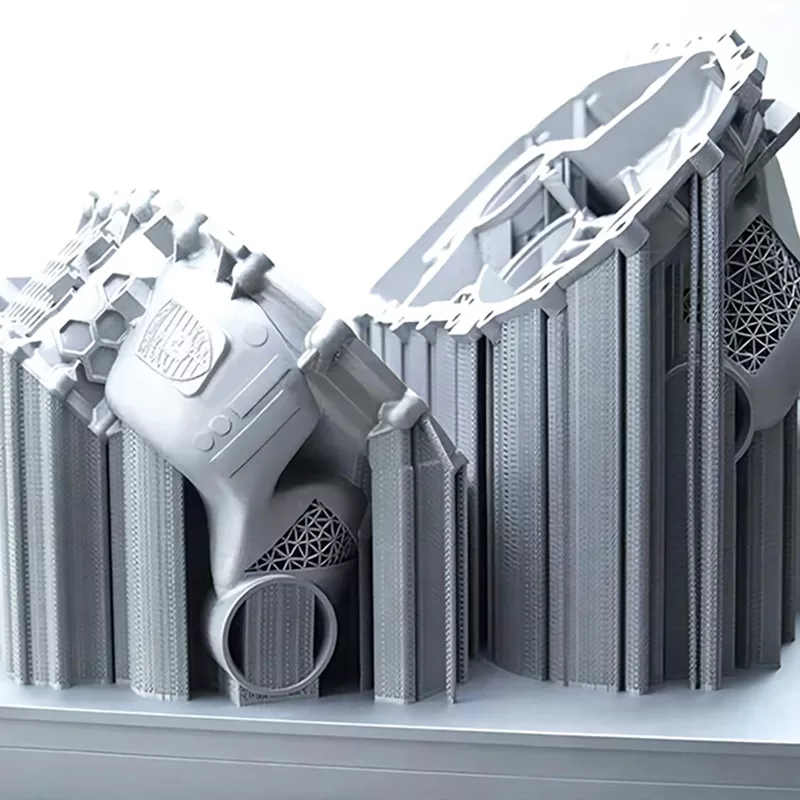

Plastic 3D printing

Our high-performance plastic 3D printing service utilizes top-quality materials to create durable parts with exceptional properties. It caters to industries such as aerospace, automotive, medical, and industrial manufacturing. With fast manufacturing cycles, customization options, and high precision, our service helps produce lighter, more efficient, and innovative parts while reducing costs.

Achieve metal 3D printing through V1 global network.

We employ various printing technologies such as Laser Powder Bed Fusion (LPBF), Electron Beam Melting (EBM), Metal Jetting, Metal Binder Jetting, and Metal Extrusion. With these techniques, we can construct fully functional metal prototypes and production parts in as little as 7 days. Our range of metal production is suitable for end-use applications.

Our 3D printing capabilities

Online 3D printing service for custom parts

Our online 3D printing service uses a variety of printing processes including FDM, SLA, SLS, PolyJet and more to convert your 3D files into high quality plastic parts. With over 120 3D printers, we have unrivalled capacity to reliably deliver parts within days. In addition to a wide range of materials, we offer a variety of post-processing options to improve appearance or enhance mechanical properties. Our online 3D printing service allows you to 3D print your custom parts on demand, whether it's a rapid prototype or a final part, we can meet your needs.

Compare 3D Printing Processes

New to our 3D printing service and not sure which additive technology is right for your 3D design? Compare the capabilities of each process below to see what fits your application's requirements.

| Materials | Max Part Size | Min Feature Size | Tolerances | |

|---|---|---|---|---|

| Metal 3D Printing | Aluminum Stainless Steel (17-4, 316L) Titanium Inconel Cobalt Chrome |

9.6 in. x 9.6 in. x 13.0 in. **X Line:** 31.5 in. x 15.7 in. x 19.7 in. |

0.006 in. | ±0.003 in |

| Stereolithography | ABS Polycarbonate Polypropylene Silicone |

29 in. x 25 in. x 21 in. | 0.0025 in. | ±0.002 in. |

| Selective Laser Sintering | Nylons Polypropylene TPU |

19 in. x 19 in. x 17 in. | 0.030 in. | ±0.010 in. |

| Multi Jet Fusion | Nylons | 11.1 in. x 14.9 in. x 14.9 in. | 0.020 in. | ±0.012 in. |

| PolyJet | Elastomer (30A to 95A) | 19.3 in. x 15.4 in. x 7.9 in. | 0.012 in. | ±0.005 in. |

| Carbon DLS | ABS Polypropylene |

7.4 in. x 4.6 in. x 12.8 in. | 0.020 in. | ±0.010 in. |

| Materials | Max Part Size | Min Feature Size | Tolerances | |

|---|---|---|---|---|

| Metal 3D Printing | Aluminum Stainless Steel (17-4, 316L) Titanium Inconel Cobalt Chrome |

245mm x 245mm x 330mm **X Line:** 400mm x 800mm x 500mm |

0.1524mm | ±0.076mm |

| Stereolithography | ABS Polycarbonate Polypropylene Silicone |

736mm x 635mm x 533mm | 0.0634mm | ±0.0508mm |

| Selective Laser Sintering | Nylons Polypropylene TPU |

482mm x 482mm x 431mm | 0.762mm | ±0.254mm |

| Multi Jet Fusion | Nylons | 281mm x 378mm x 378mm | 0.508mm | ±0.305mm |

| PolyJet | Elastomer (30A to 95A) | 490mm x 391mm x 200mm | 0.305mm | ±0.127mm |

| Carbon DLS | ABS Polypropylene |

89mm x 118mm x 326mm | 0.508mm | ±0.254mm |

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our plastic company, v1plastic.

| Category | 3D Printing Materials |

|---|---|

| Metals | Stainless Steel, Aluminum, Titanium, Inconel, Copper, Cobalt Chrome, Tool Steel, Bronze, Brass |

| Plastics | PLA, ABS, PETG, Nylon, TPU, Polycarbonate, PEEK, Polypropylene, Polyethylene, TPE |

| Elastomers | TPU (Thermoplastic Polyurethane), TPE (Thermoplastic Elastomer), Silicone |

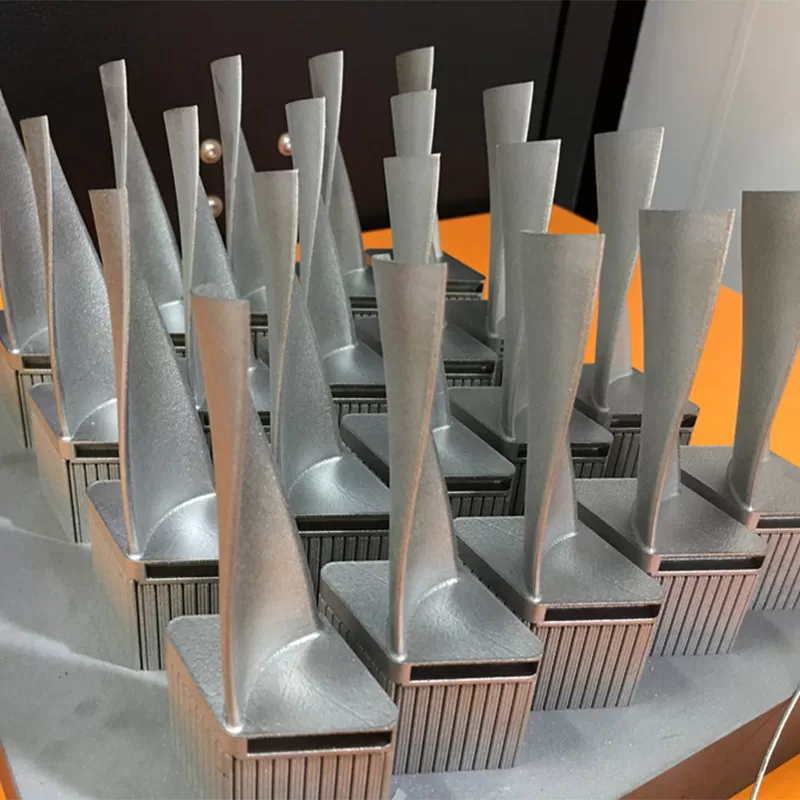

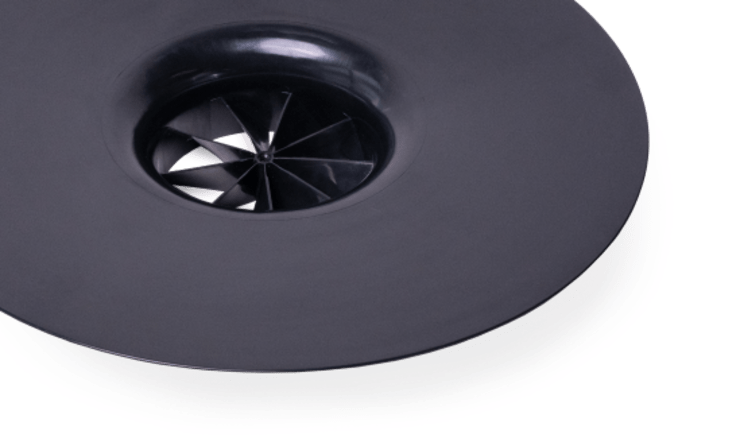

Gallery of 3D printed parts produced by V1

With over 65,000 customers in every industry, including aerospace, defence, robotics, medical, machinery, automotive and electronics, we have extensive experience in meeting a wide range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection moulded prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, fixtures and durable end parts.

The V1 standard - consistent quality, every time

V1 takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Every order is dimensionally and visually checked to ensure it meets the V1 standard.

Some of our vetted manufacturing partners

Source parts with V1's custom 3D printing services

V1 offers a comprehensive range of additive manufacturing solutions for the production of custom parts. From single or low-volume prototypes for rapid product development, to intricate and highly durable end-use parts for high-volume production, our 3D printing services enable you to source parts efficiently without compromising on quality. We offer a wide range of production polymers, including PLA, PETG, ABS and nylon, and our manufacturing partners are always offering newer and more robust plastics. For metal 3D printing, speak to an account manager or explore what V1 has to offer. Our 3D printing capabilities make it easier to produce complex end-use components or hold your product in your hands for the first time, all without having to wait for quotes.

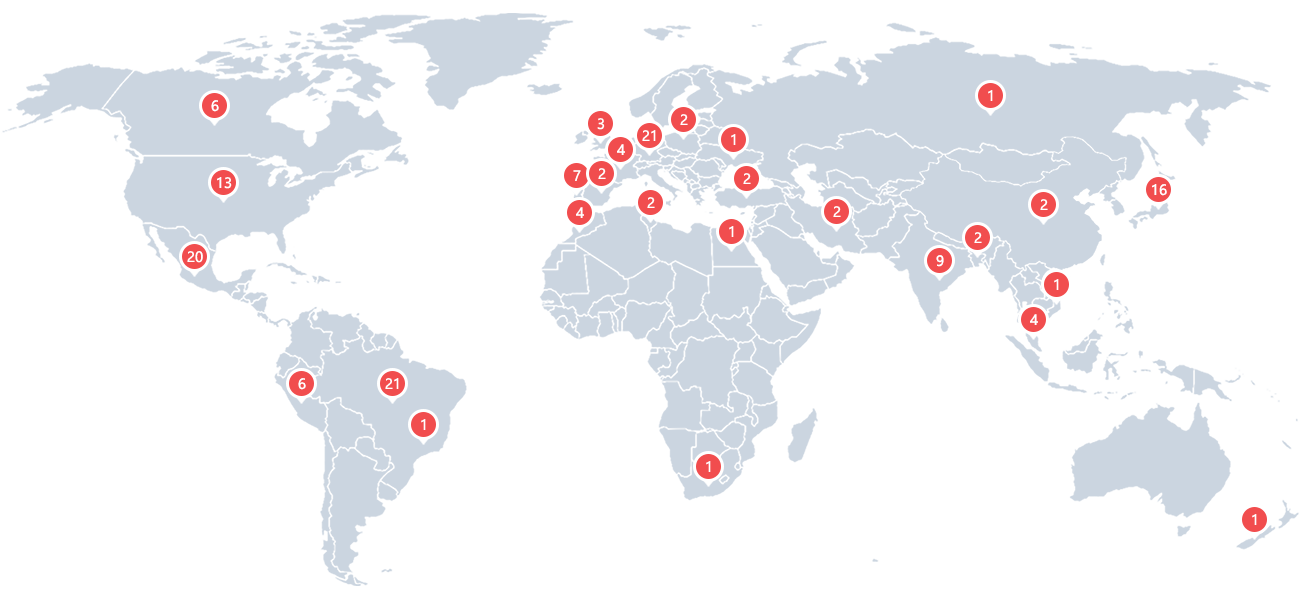

A network built for professional 3D printing services

Our network of manufacturing partners brings together highly professional and specialised 3D printing companies. The 3D printing partners we work with are highly skilled at producing prototypes and production-ready parts using technologies such as Fused Deposition Modelling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). This network of experienced and passionate additive manufacturers can produce parts using specialised printers such as the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project and Viper line. So no matter what type of parts you need, we have access to shops with professional skills and limitless capacity.

Industrial 3D Printing Services for Manufacturing & Tooling

3D printing technology has evolved from a low-cost process for rapid prototyping. There are now many larger, more advanced 3D printers for larger batch sizes of parts and for using materials other than polymers. Technologies such as industrial FDM and SLA, SLS and MJF are being used for more industrial purposes such as higher volume production and tooling. 3D printing is ideal for producing cheaper moulds for injection moulding, which reduces the overall cost of mass-producing plastic parts. Industries such as automotive, medical, electrical and even toys are using industrial 3D printing technology as a viable alternative to traditional industrial processes such as CNC machining and injection moulding. With 3D printing, you can speed up and reduce the cost of industrial-scale production.

Frequently Asked Questions

Online 3D Printing Service FAQ

- What are viable alternatives to powder coating?

If you're looking to replace powder coating with another finishing option, we recommend wet painting.

- How will powder coating affect the price of my part?

For a standard metal (such as aluminium 6061) powder coating will add approximately 15% to the production price. This can vary depending on the complexity of the job.

- How durable is powder coating?

Powder coated parts typically last up to 20 years. Constant exposure to UV light and the outdoors, as well as general overuse, will cause the powder coating to deteriorate more quickly.

- What are the best applications for powder coating?

Powder coating makes metal parts resistant to outdoor conditions, including heat, cold damage and corrosion. You're likely to find powder coating on parts used in agricultural equipment, industrial machinery and heavy-duty automotive applications.

- When should you powder coat?

Powder coating provides a cost-effective, tough and durable finish to your parts, increasing their longevity and resistance to harsh environments. This makes it ideal for marine applications, for example.

What can you do with V1's custom 3D printing service?

V1 offers a comprehensive range of additive manufacturing solutions for all applications, from single or low-volume parts for rapid prototyping to complex functional parts for high-volume production. Our online 3D printing service enables you to produce parts faster and more cost-effectively, so you can accelerate your innovation cycle and focus on creating breakthrough products.

We work with a global network of manufacturing partners using four key technologies Fused Deposition Modelling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) and HP's Multi Jet Fusion (MJF). Through our vetted manufacturing network, we can produce parts on specialist 3D printers such as the Stratasys Fortus line, EOS P390, Markforged Mark 2, HP MJF 5210, 3D Systems Project and Viper line. So no matter what type of parts you need, we have access to the ideal technologies for your designs.

We offer a wide range of build polymers, including PLA, PETG, ABS and nylon, and our manufacturing partners are always offering newer and more robust plastics. For metal 3D printing, speak to an account manager or explore what V1 has to offer. Our 3D printing capabilities make it easier to produce complex end-use components or hold your product in your hands for the first time, all without having to wait for quotes.

Our other manufacturing capabilities

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±.0008” (0.020 mm)

- Lead times from 5 business days

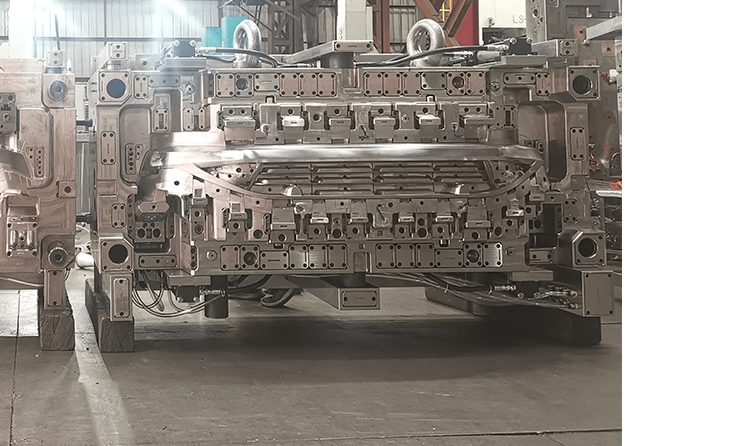

Mould Manufacturing

Injection mould design, manufacture, production and finishing

- Focus on automotive and white goods mould making

- Over 1000 square metre injection moulding factory and workshop

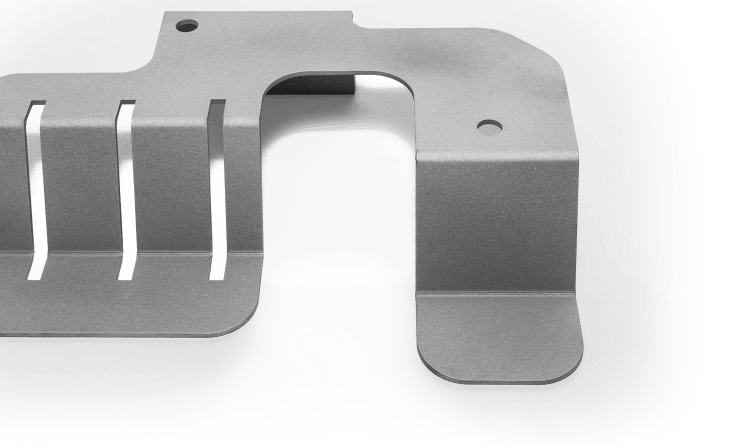

Sheet metal fabrication

Laser cutting, bending, post-processing

- 6 metals & 9 surface finishes

- Tolerances down to ±.004” (0.010 mm)

- Lead times from 5 business days

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M parts