Injection Molding Service

Access a wide range of bespoke services from our specialist network of injection molding companies. Prototype and production tooling. Upload your parts for a free quote and expert feedback.

Our custom injection molding services

Create parts of any complexity from 3mm (0.12in) to 2m (79in) in size with V1. Lead times are as short as 10 days and we offer local or global production options. Our manufacturing partners typically use 20 to 3,000 tonne injection molding machines, depending on part size, complexity and volume. DIN 16901-130 and tighter tolerances are available on request.

Plastic Injection Molding

Insert Molding

OverMolding

Liquid silicone rubber Molding

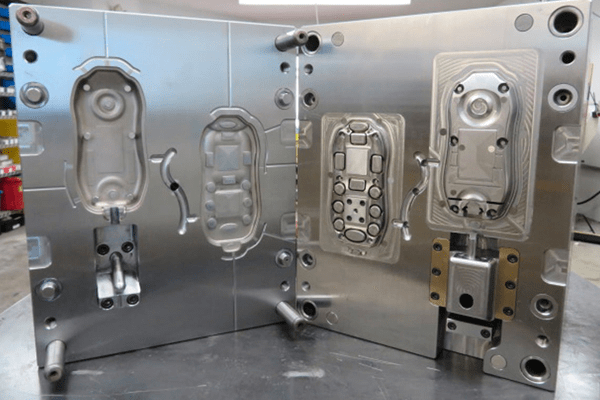

Tooling - prototyping vs production

Prototyping

Ideal for rapid prototyping and low volume production

- Tool life - 1k to 100k units

- Fast turnaround and cost effective design

- Aluminium or steel

Production

Longer-lasting tooling for larger volumes

- Tool shot life – 100k to 1M units

- Automated production for cost-efficiency at higher volumes

- Hardened steel for longer life and a scalable unit price

Secondary operations

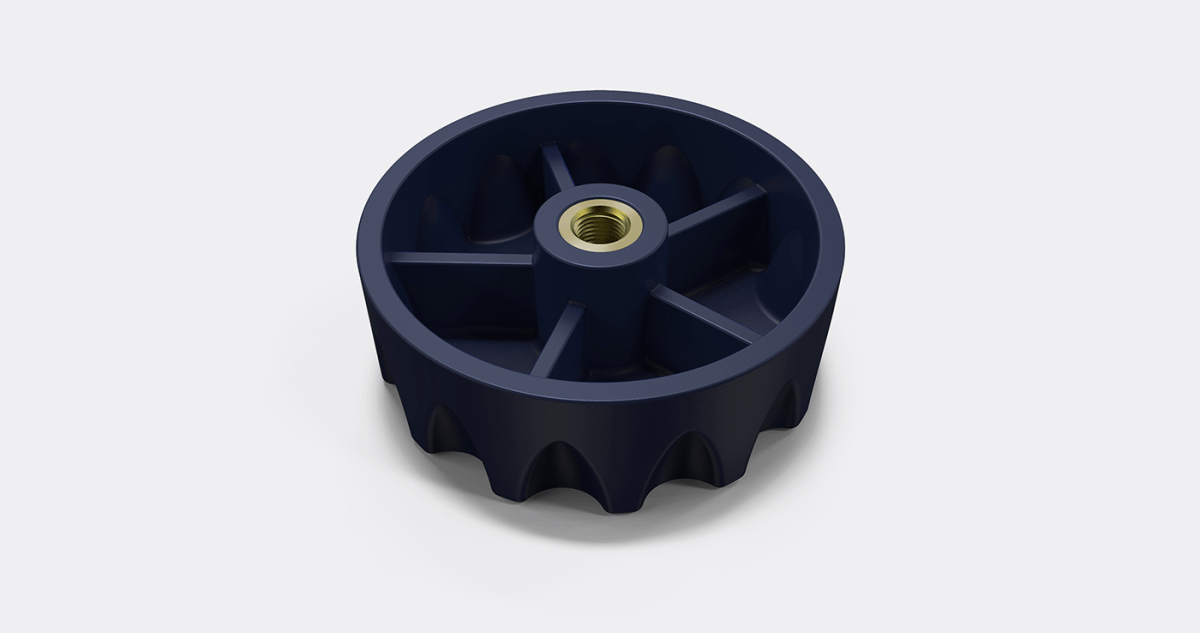

We offer a range of secondary operations such as painting or heat tapping inserts. You can specify which secondary operations are required in the "Custom Requirements" section of your quote request. Here are some examples of the secondary operations we offer:

- Inserts

- Pad Printing

- Painting

- Silk screening

- Ultrasonic welding

- Laser engraving

- UV coating

- Heat staking

- Hot stamping

- Post-mold machining

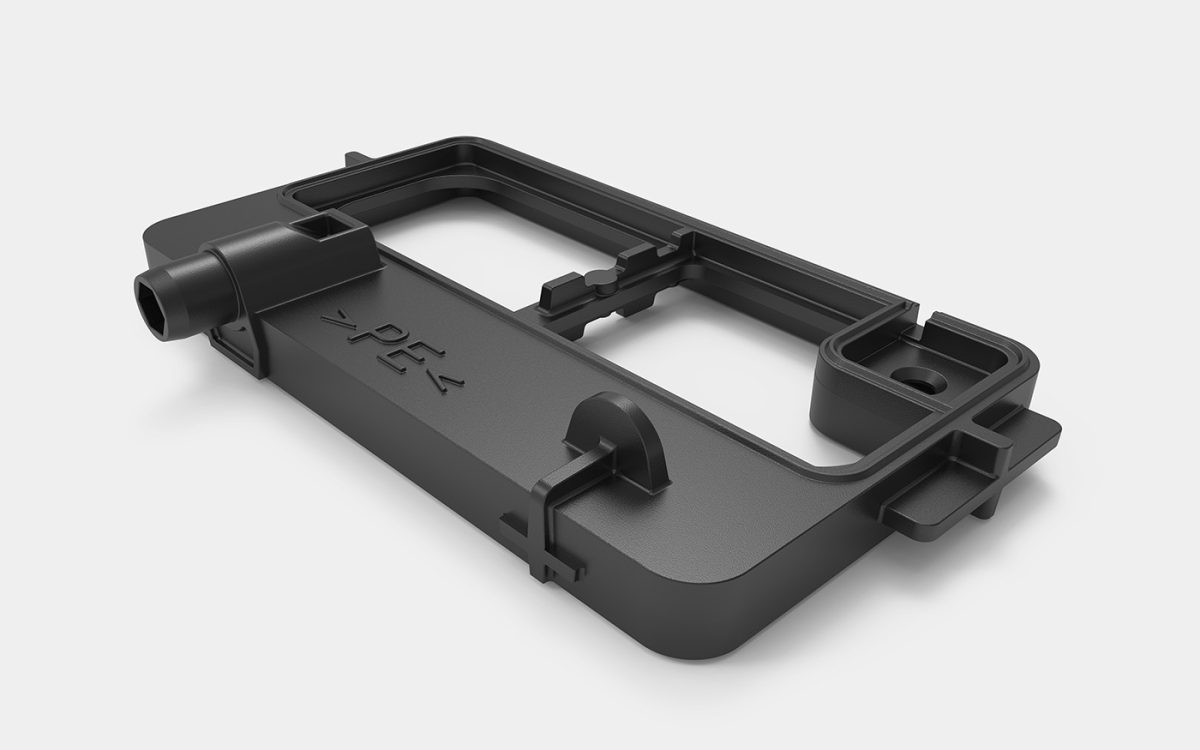

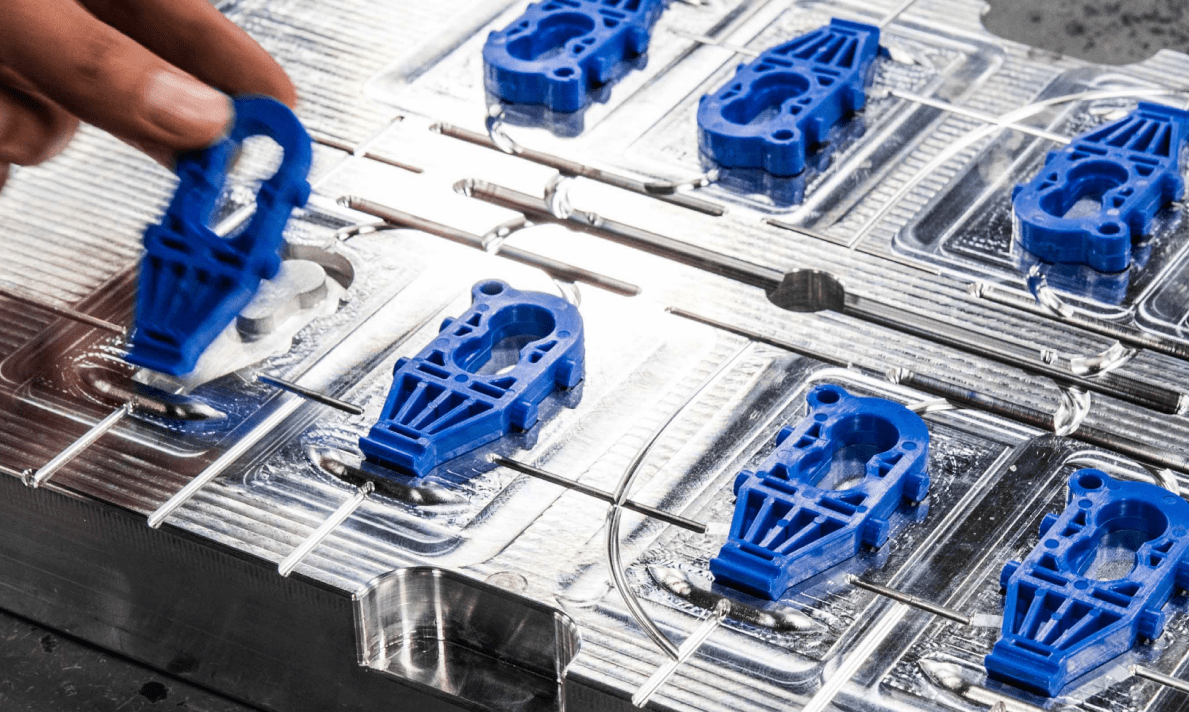

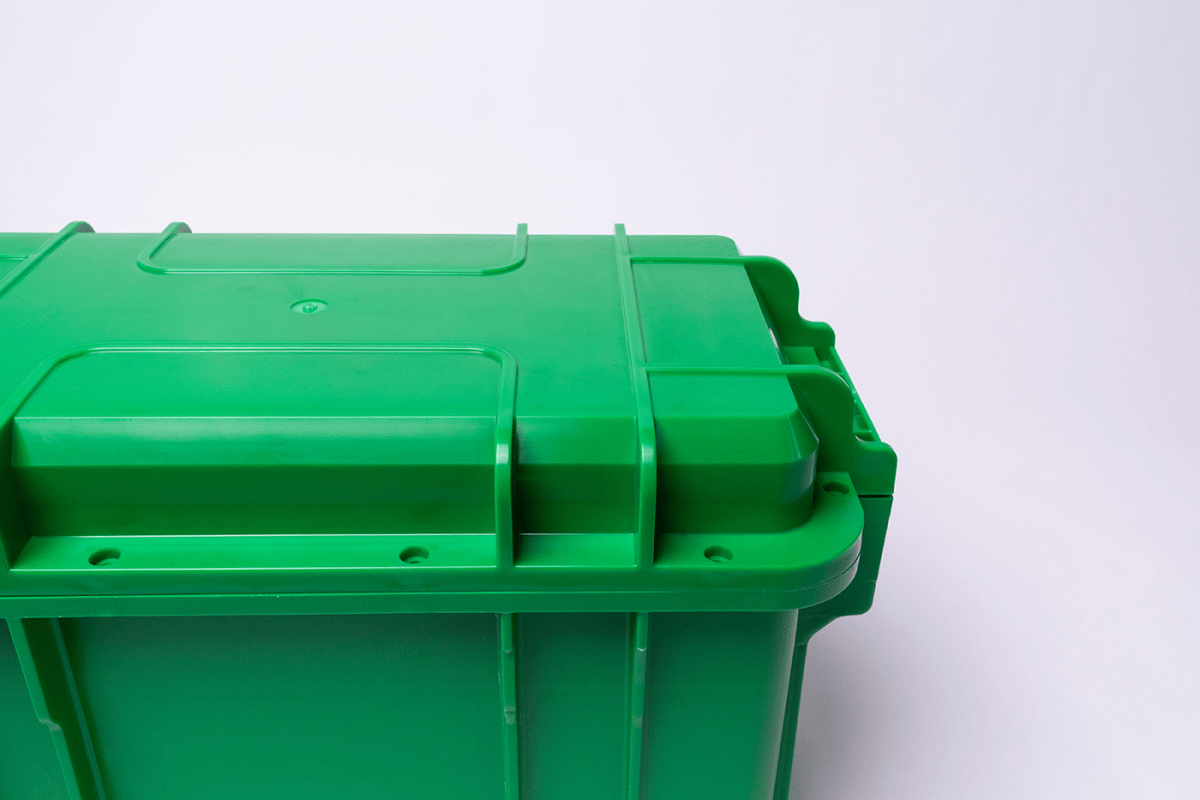

Plastic injection molded products manufactured by V1

Injection molding surface finishes

We can provide any level of surface finish from SPI and VDI standards, based on the product's aesthetic and functional requirements, to achieve the ideal surface effects for injection molded parts. We also offer secondary surface treatments to further enhance the product surface texture.

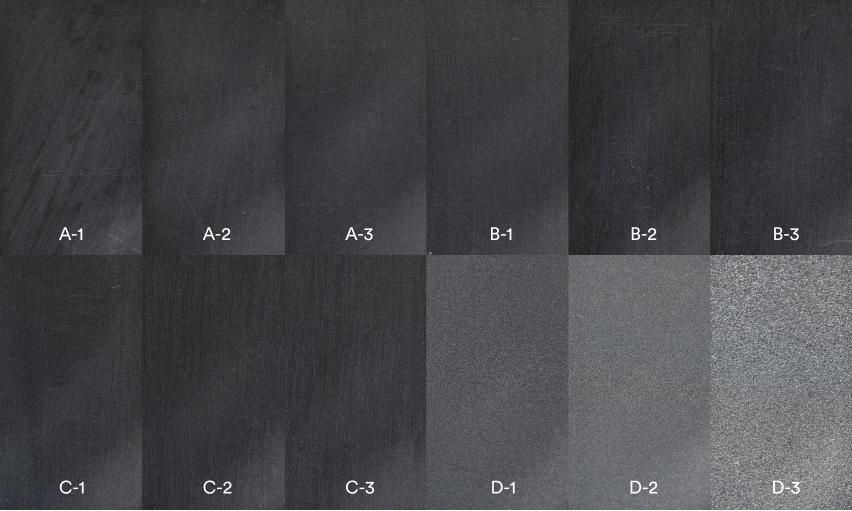

SPI surface finishes

SPI Surface Finish Levels:

- A-1: High gloss surface, high transparency, using polished mold surface.

- D-2: Skin TEXTURE SURFACE, using sanded or etched mold.

- D-3: Coarser skin texture surface, typically from shot blasting.

*SPI: Society of the Plastics Industry (USA)

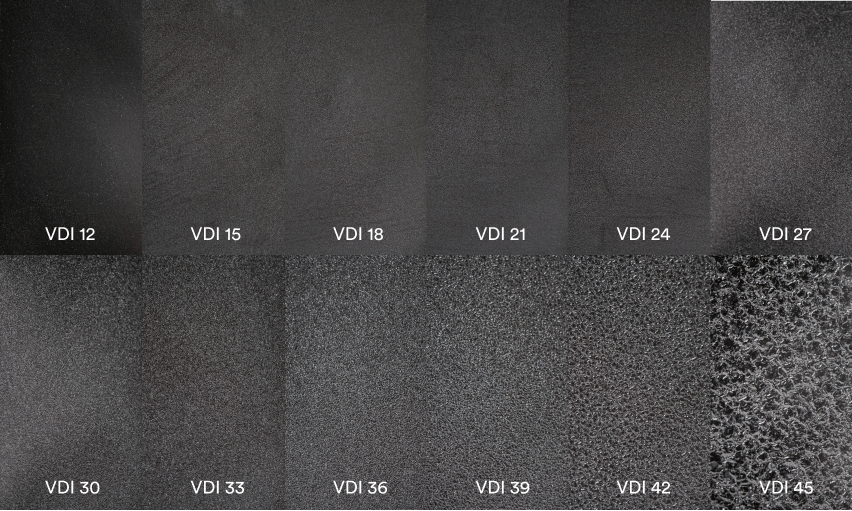

VDI surface finishes

VDI Surface Finish Levels:

- VDI 28: High gloss finish, using polished mold surface.

- VDI 30: Fine textured finish, using lightly blasted mold.

- VDI 33: Coarser skin texture, typically from mechanical blasting.

*VDI: Association of German Engineers

Injection molding materials

Injection molding uses a huge range of plastics, making it ideal for many applications across nearly every industry. We can source thousands of materials on request. Please contact 3dprinting@v-1.com for specific material requests.

| Property | Materials |

|---|---|

| Impact resistant | ABS, PMMA, PVC, PE, PC |

| Wear-resistant | POM, PEEK, UHMW |

| Dimensional stability | ABS, PBT, HIPS, PPS |

| Chemical resistance | PEEK, PP, PBT, PE, LDPE, PA |

| Rubber like | TPU, TPE, Silicone |

| Cost-efficient | PP, HDPE, LDPE |

| Cosmetic | ABS, PC, HIPS |

How we manage your injection molding project

1. Upload your design

Upload your parts to our platform to have your project reviewed by our team

2. Receive a quote

Your account manager will work with our technical team and manufacturing partners to provide you with a quotation within 48 hours.

3. DFM & Tool Approval

Receive comprehensive Design For Manufacturing analysis for approval before construction of your tooling begins

4. Receive T1 samples

We will send you a golden sample for approval before production begins.

5. Production & Delivery

We produce & deliver your parts to match the gold sample

6. Reorder as needed

You can easily reorder parts by contacting your account manager

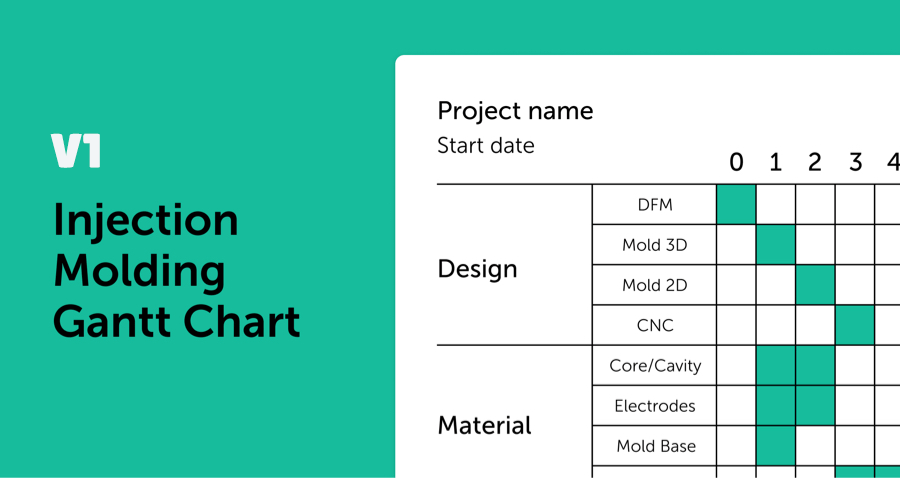

The Injection Molding timeline

Ready to start injection molding? Download our Gantt chart to help keep your injection molding project on time, on budget and to specification.

The V1 Standard guarantees consistent quality every time.

V1 applies strict standards to all custom parts, ensuring the quality and consistency of the injection-molded components. We inspect each order thoroughly, both visually and dimensionally, during and after production.

Tolerances & dimensional accuracy

Learn more

Mold finish standards

Learn more

Quality control procedures

Learn more

FAQ’s

Several factors determine the cost of molding custom parts through injection. The primary costs are tooling, materials, and production. To reduce your manufacturing costs, refer to our injection molding guide.

Ownership of the injection mold is under question.

Custom tooling will always be owned by the customers; however, the manufacturing partner (MP) acquires any reusable proprietary components they develop. The MP is responsible for keeping all custom tooling at their facility for at least two years, unless they agree to do otherwise. If the tooling remains inactive for two years, the maintenance provider (MP) may contact V1 to assess the need for retaining the tool for a longer period. V1 will subsequently get in touch with the customer to make additional arrangements. The mold can be moved to any desired location at the requester's expense and upon request.

If a manufacturing partner exits the V1 network, we bear the cost of transferring all molds to another partner in the network to ensure timely delivery of your parts.

Generally, we can have the Request for Quotation (RFQ) ready within 24 hours. Setting up the mold, ordering and processing the materials takes two days, and an additional day is required for packing and sending the order out for shipment. The manufacturing time required will be directly proportional to the volume of parts you require.

We work with a network of injection molding companies specialized in ISO 9001 and ISO/TS16949 certifications.

Our other manufacturing capabilities

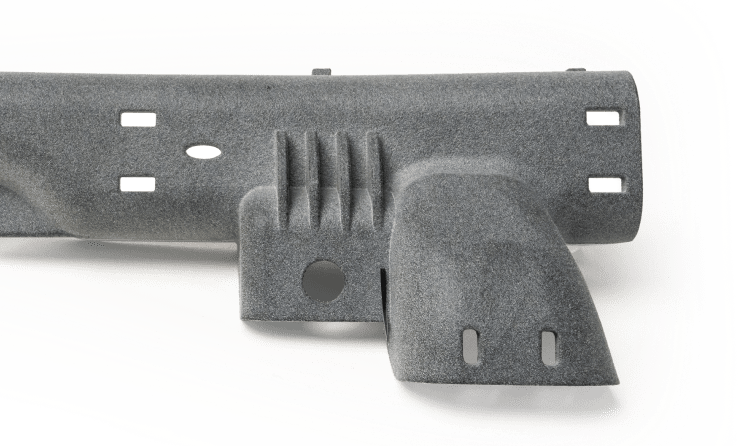

3D printing

FDM, SLA, SLS, MJF、SLM

- 25+ plastics & 35+ colors

- ±0.5% dimensional accuracy with a lower limit down to ±0.0059 in (0.15 mm)

- Lead times from 1 business day

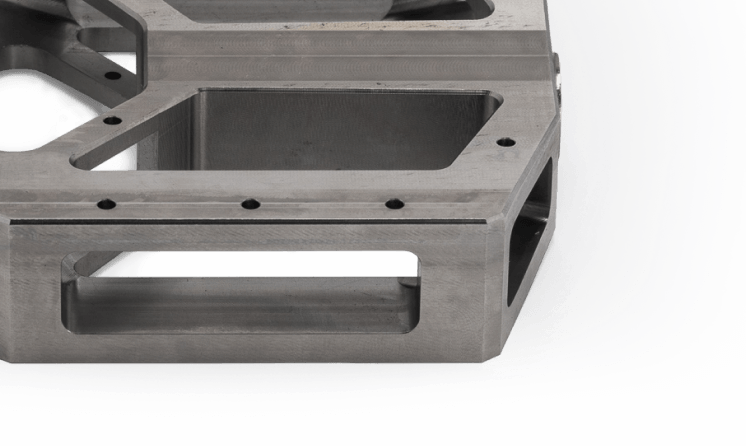

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

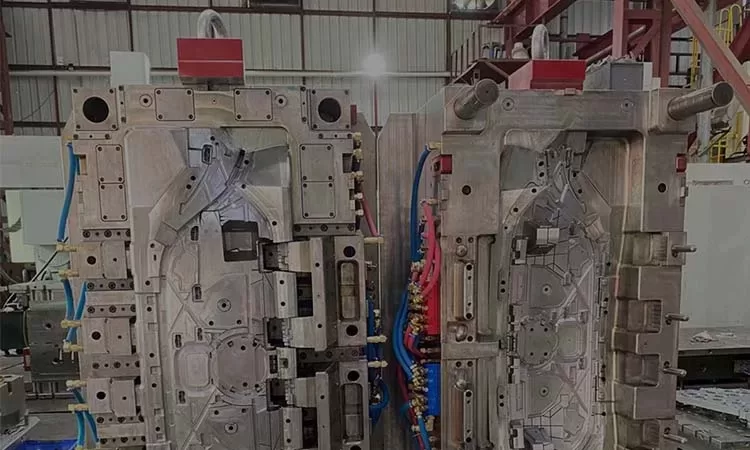

Mold Manufacturing

Precision CNC Machining, EDM, Post-Processing

- Tolerances down to ±0.005 mm

- Lead times from 5 business days

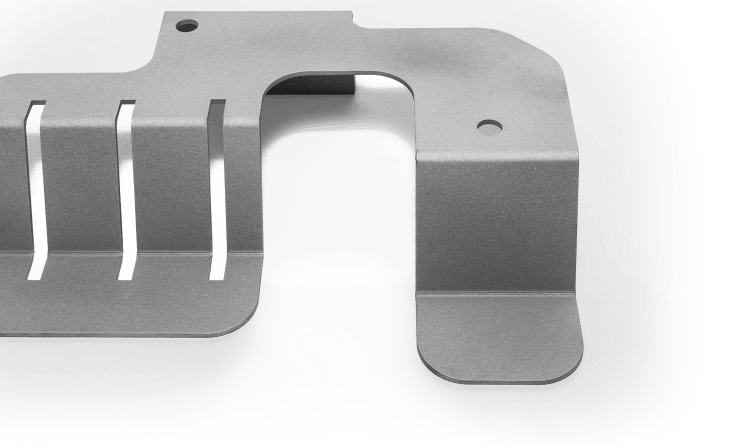

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days