FDM 3D printing service

Get high-performance parts for rapid prototyping and low-volume industrial production with FDM 3D printing. We offer FDM for rapid manufacturing in a variety of robust materials for many use cases and can print parts in 1 day.

What is FDM 3D Printing?

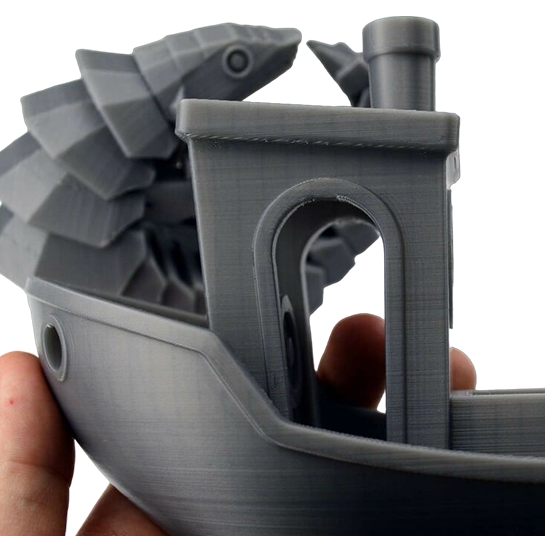

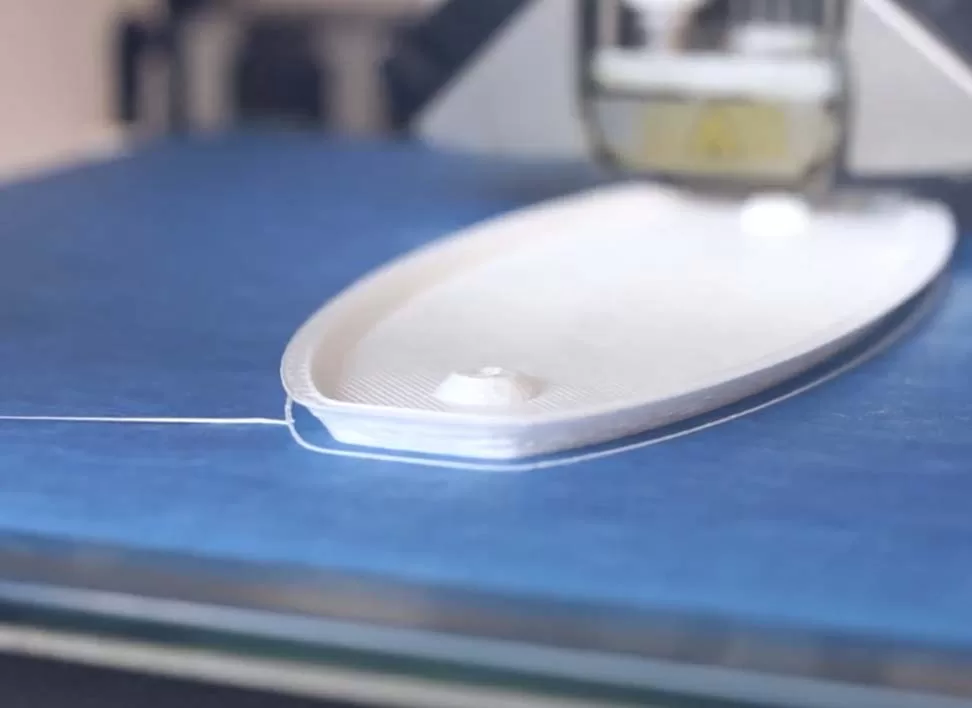

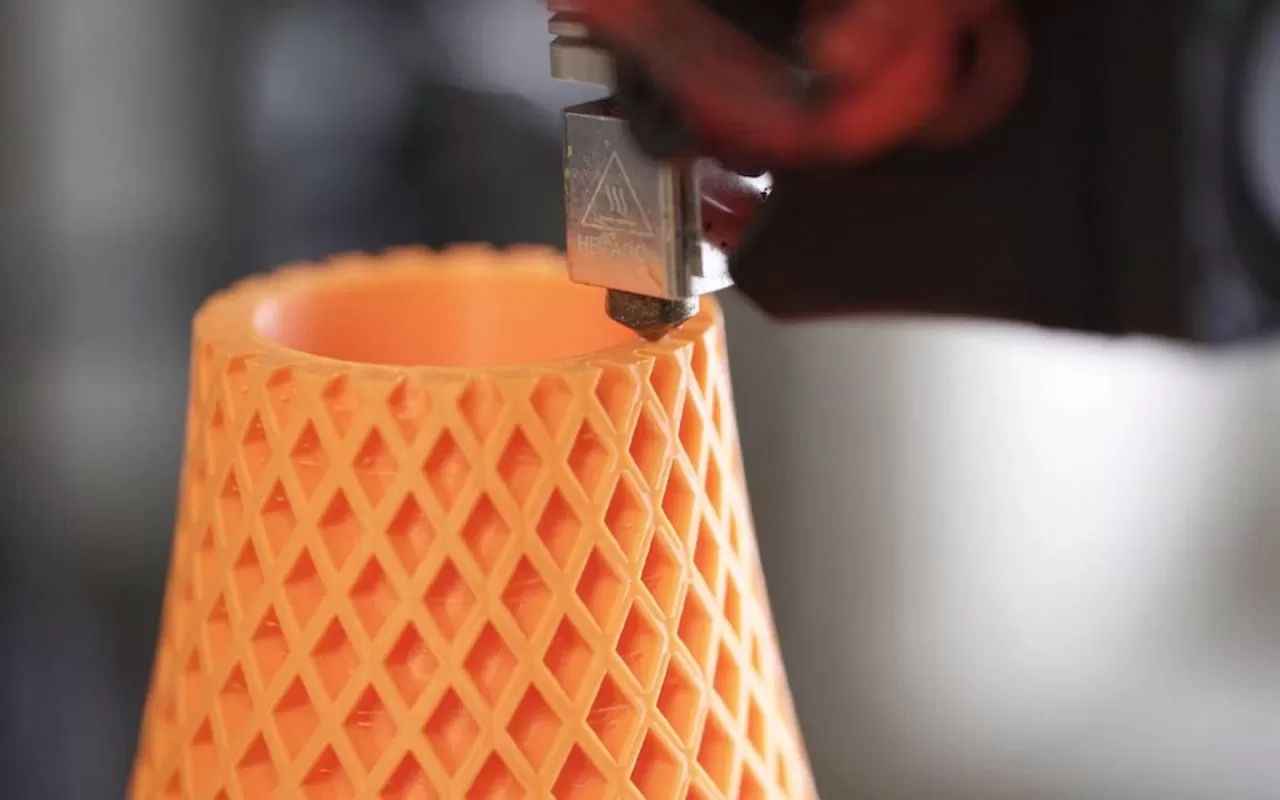

FDM 3D printing, also known as Fused Deposition Modelling or FFF, is a popular and affordable 3D printing process. It works by melting a plastic filament and layering it to create a three-dimensional object. FDM printers are versatile and can use a wide range of materials. They are commonly used in industries such as product design, engineering and manufacturing to create prototypes and functional parts with complex shapes. FDM 3D printing is known for its ease of use and ability to produce detailed objects quickly and cost-effectively.

Fused Deposition Modelling (FDM) capabilities

FDM 3D printing has two distinct classes: prototyping (desktop) FDM and industrial FDM. These are the key capabilities of both technologies.

| Maximum build size | Standard lead time | Dimensional accuracy | Layer height | Infill | |

|---|---|---|---|---|---|

| Prototyping FDM | 500 x 500 x 500 mm (19.68 in x 19.68 in x 19.68 in) | From 2 business days | ± 0.5% with a lower limit on ± 0.5 mm (0.0196 in) | 100-300 μm | 20-80% |

| Industrial FDM | 406 x 355 x 406 mm* (15.98 x 13.97 x 15.98 in) | 3 business days | ± 0.25% with a lower limit: ± 0.25 mm (0.01 in) | 100-300 μm | Ultra-light, Light, Solid |

Materials available for FDM 3D printing

FDM material prototyping

Ideal for fast and affordable rapid prototyping and modelling.

- PLA

- PETG

- ASA

- ABS

- TPU

Industrial FDM Materials

Ideal for high volume production and larger parts with better mechanical properties.

- Nylon: Forged Onyx

- PEI: ULTEM 9085, ULTEM 1010

- ASA: Stratasys ASA

- ABS: ABS M30, ABSplus

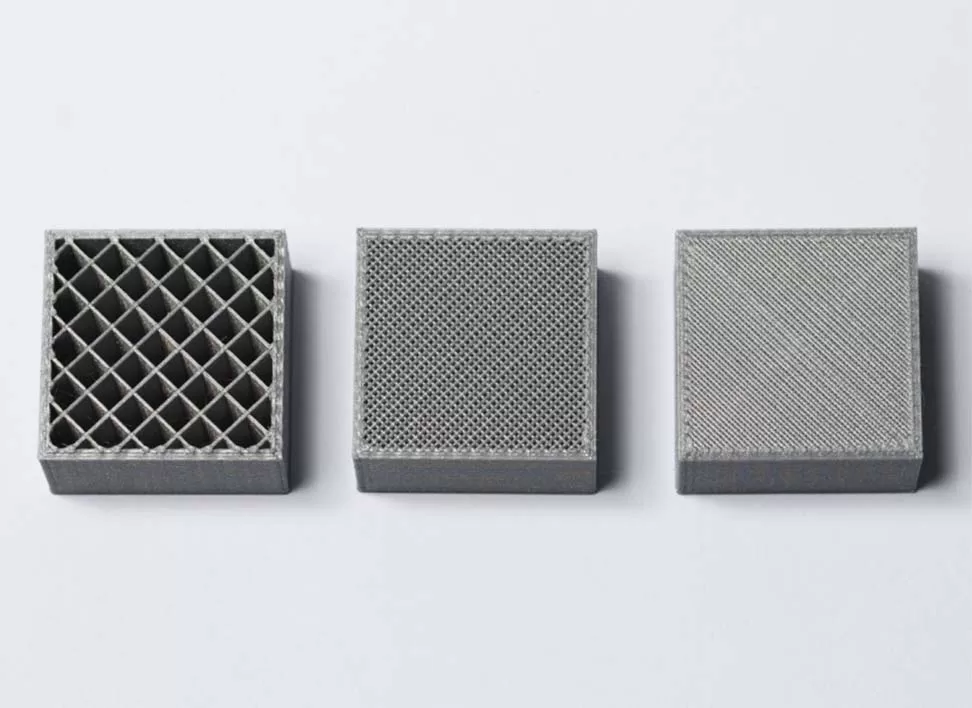

FDM fill options

For prototyping FDM, you can choose from 20%, 30%, 40%, 60% and 80% infill.

The infill options available for industrial FDM are the same as those offered by Stratasys.

- Solid - Stratasys' solid build style

- Light - Stratasys' Sparse Double Dense build style

- Ultra-light - Stratasys' Sparse build style

Comparison of FDM with other 3D printing processes

| Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|

| FDM | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787'') |

| Industrial FDM | ± 0.25% with a lower limit: ± 0.25 mm | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787'') |

| Prototyping SLA | ± 0.5% with a lower limit of ± 0.15 mm | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787'') |

| Industrial SLA | ± 0.2% with a lower limit of ± 0.127 mm | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787'') |

| SLS | ± 0.3% with a lower limit of ± 0.3 mm | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196'') |

| MJF | ± 0.3% with a lower limit of ± 0.3 mm | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9'' x 11.2'' x 14.9'') | 80μm | 0.5 mm (0.0196'') |

We have high standards for FDM 3D printing

We produce your custom parts to strict manufacturing standards, ensuring that all parts and processes comply with the Hubs Standard. A thorough review of these requirements is included in our inspection report that we send with every order.

- Consistent surface finish with no dents or delamination. Marks from retraction and layer changes are acceptable.

- All backing material is removed so that the supported surface has a consistent finish.

- All parts are printed with 3 outline / perimeter shells or a wall thickness of 1.2mm.

Advantages and drawbacks of FDM 3D printing

It's important to consider these advantages and drawbacks when deciding whether FDM 3D printing is the right choice for your specific application or project.

Advantages

- Cost-effective: FDM 3D printers are relatively affordable compared to other 3D printing technologies, making them accessible to individuals, small businesses, and hobbyists.

- Wide range of materials: FDM supports a variety of materials, including thermoplastics such as ABS and PLA, as well as specialty filaments with unique properties like flexibility, conductivity, and flame resistance.

- Ease of use: FDM printers are user-friendly and easy to set up, requiring minimal technical expertise. They are suitable for beginners and those new to 3D printing.

- Large build volume: FDM printers are available in various sizes, allowing for the creation of large-scale prints or multiple smaller prints simultaneously.

- Support structures: FDM allows for the creation ofsupport structures that can be easily removed after printing, enabling the production of complex geometries and overhangs.

Drawbacks

- Lower resolution: Compared to some other 3D printing technologies, FDM has relatively lower resolution, resulting in visible layer lines on the printed object's surface.

- Limited detail: FDM may struggle to reproduce intricate details or fine features accurately. The minimum achievable feature size is typically larger compared to high-resolution technologies like SLA or DLP.

- Post-processing requirements: FDM prints often require post-processing, such as sanding or smoothing, to improve surface finish and remove visible layer lines.

- Mechanical anisotropy: FDM parts can exhibit mechanical anisotropy, meaning their strength and properties may vary depending on the direction of printing layers. This can affect the performance of functional parts.

- Material limitations: While FDM supports a wide range of materials, it may not be suitable for applications requiring high-temperature resistance or extreme durability. Certain advanced materials may not be compatible with FDM printers.

Design guidelines for FDM

The table summarises the recommended and technically feasible values for the most common features found in FDM 3D printed parts.

| Feature | Recommended size |

|---|---|

| Unsupported walls | 0.8 mm (0.0315 in) |

| Supported walls | 0.8 mm (0.0315 in) |

| Minimum feature size | 2.0 mm (0.0787 in) |

| Minimum hole diameter | 2.0 mm (0.0787 in) |

Our other 3D printing processes

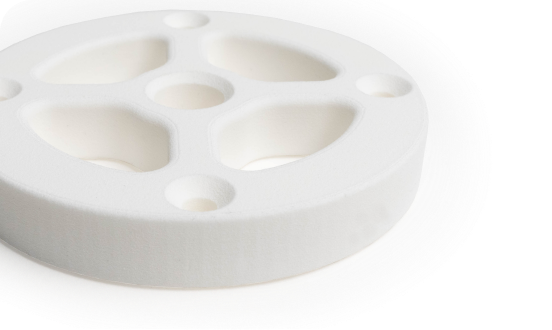

SLA

Visual prototyping

Dimensional accuracy of ± 0.5% with a lower limit of ± 0.15 mm (± 0.006")

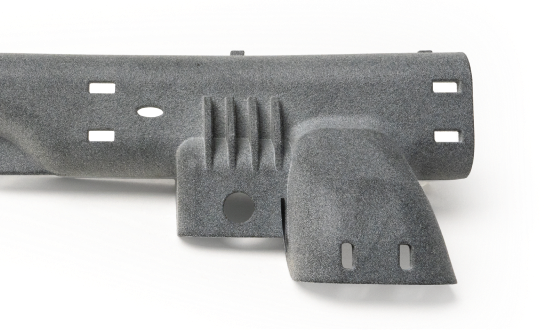

SLS

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.0118")

MJF

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit on ± 0.3 mm

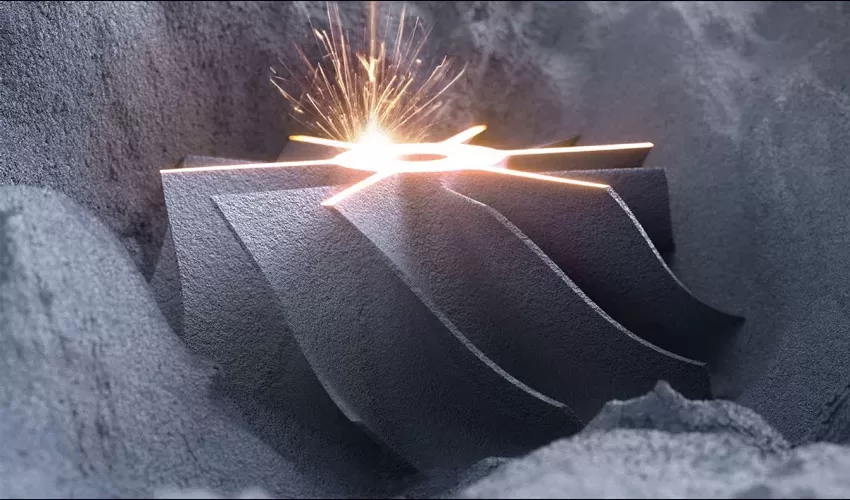

SLM

High-precision metal manufacturing

- Dimensional accuracy of ± 0.1% with a lower limit: ± 0.1 mm

- Suitable for complex and detailed metal parts

- Lead times from 2-3 business days