SLA 3D Printing Service

Get high-performance parts for rapid prototyping and production with Hubs' SLA 3D printing service. We offer tonnes of prototyping and industrial resin materials and can print parts in as little as 1 day.

What is SLA 3D Printing?

Stereolithography (SLA), also known as resin 3D printing, is a 3D printing technology that produces parts with high resolution and accuracy, fine detail and smooth surface finishes. Part of the vat photopolymerisation printing family, SLA technology uses photosensitive thermoset polymers to produce custom parts. We use Formlabs materials for rapid prototyping and 3D Systems Accura materials for large scale production.

SLA 3D Printer Capabilities

SLA 3D printing has two distinct classes: prototyping (desktop) SLA and industrial SLA. These are the key capabilities of each technology.

| Maximum build size | Standard lead time | Dimensional accuracy | Layer height | Minimum feature size | |

|---|---|---|---|---|---|

| Prototyping (desktop) SLA | 145 × 145 × 175 mm (5.7 in x 5.7 in x 6.8 in) | From 3 business days | ± 0.5% with a lower limit of ± 0.15 mm (± 0.006 in) | 50-100 μm | 0.2 mm |

| Industrial SLA | 500 x 500 x 500 mm (19.68 in x 19.68 in x 19.68 in) | From 3 business days | ± 0.2% with a lower limit of ± 0.127 mm (±0.005 in) | 50-100 μm | 0.2 mm |

SLA 3D printed parts come in many materials

Leading companies and engineers who need to iterate quickly or get strong industrial plastic parts faster use V1 for our range of prototyping and production materials.

Prototyping (Desktop) SLA Materials

Ideal for accurate visual prototypes with smooth surface finishes.

- Standard Resins:

- ABS-like Resin - Mimics properties of ABS plastic

- Resin for Visual Prototyping - For concept models

- Draft Resin - Cost-effective option for fit and assembly tests

- Engineering Resins:

- Tough Resin - Impact resistant prototypes

- Durable Resin - Functional prototypes with improved temperature resistance

- Castable Resin - Burnouts for metal casting processes

- Dental Resins:

- Model Resin - For dental models like crowns, bridges, aligners

- Guide Resin - Surgical guides for dental procedures

- Try-in Resin - Temporary crowns and bridges

- Jewelry Resins:

- Castable Wax Resin - Burnouts for lost-wax casting of jewelry

- Moldable Wax Resin - For making wax injection molds

- Specialty Resins:

- Clear Resin - Optically clear parts

- Flexible Resin - Rubber-like resins for snap fits

- Heat Resistant Resin - For prototypes needing higher temperature resistance

Industrial SLA materials

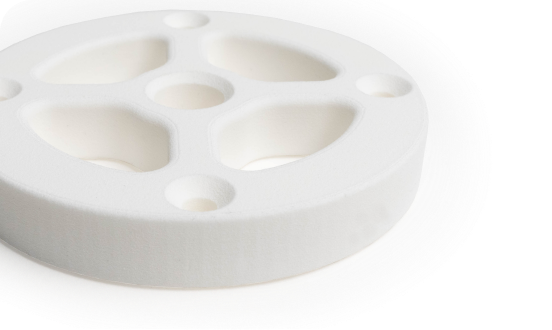

Ideal for durable functional prototypes and high precision parts with smooth surface finishes.

- Standard Resins:

- Accura Family - Accura 25, 60, 48LT, Xtreme, Bluestone for general purpose prototyping

- Engineering Resins:

- Somos PerFORM - High temperature resistance and toughness

- Somos Element - UL 94 V-0 flame retardance rating

- Somos NeXt - High stiffness and heat resistance

- Dental Resins:

- NextDent Model - For dental models like crowns, dentures

- NextDent SG - Elastic material for dental gingiva masks

- NextDent Cast - Burnout material for metal casting

- Jewelry Resins:

- Solidscape Castable Wax - High detail wax for jewelry casting

- End-Use Production Resins:

- MED610 - USP Class VI and ISO 10993 certified for medical devices

- Watershed 11122XC - Low-moisture pickup and long-term environmental stability

- Siraya Tech Blu - Heat and moisture resistant resin

- Composite Resins:

- Carbon Fiber Reinforced - 35% stronger composite parts

- Fiber Glass Reinforced - High stiffness composite prototypes

Post-processing for SLA

Standard (No Additional Post-Processing)

For SLA (stereolithography) 3D prints, typical post-processing steps may be required to achieve the desired final appearance and properties. These steps include:

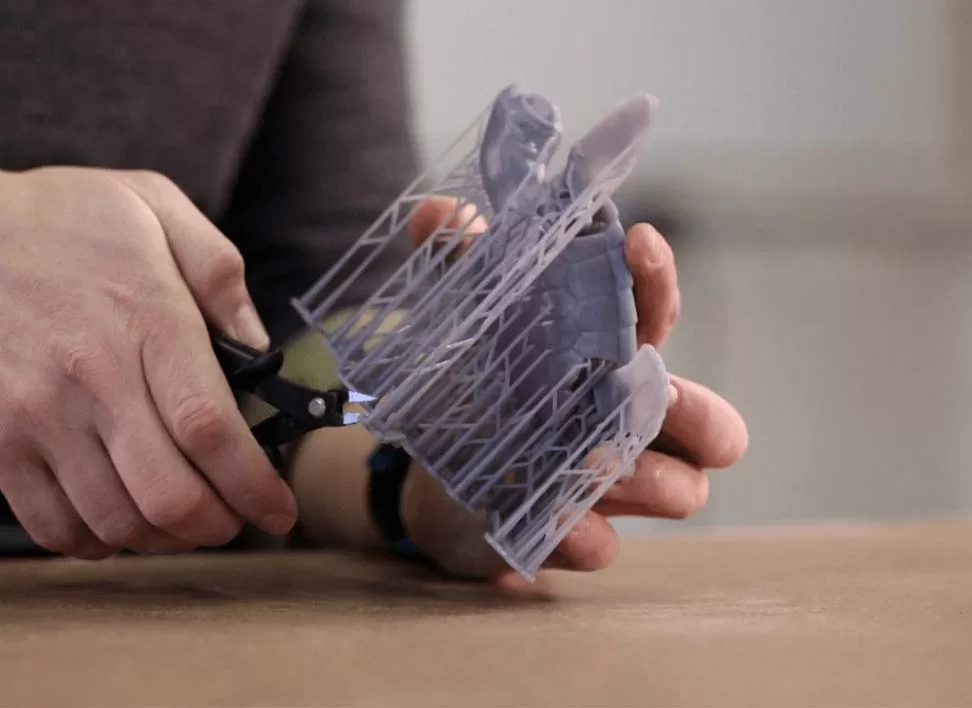

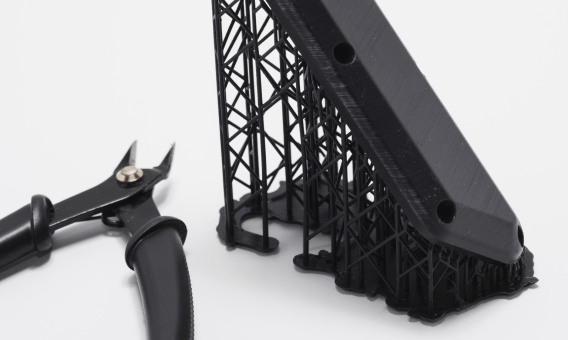

Support removal: Carefully removing support structures created during printing using tools like tweezers or pliers. Sanding smooth any remaining support pins or rough edges.

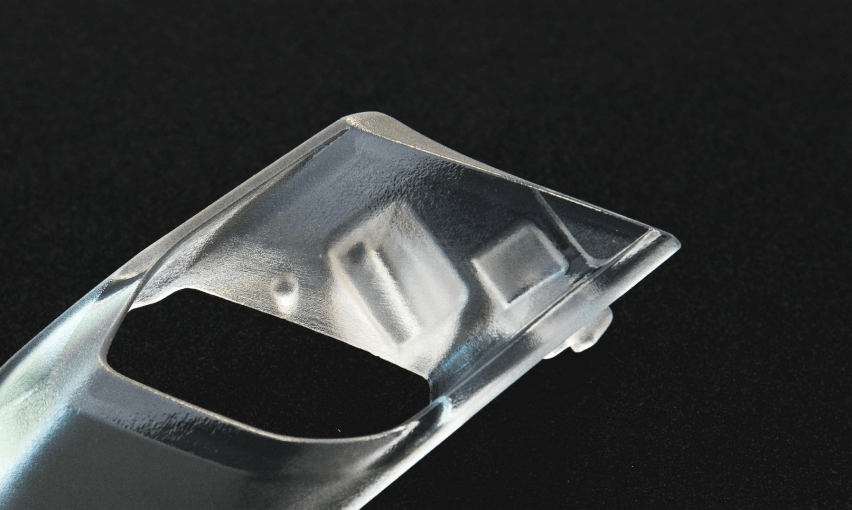

Polishing (for clear resins): Additional polishing steps may be needed for clear resin prints to enhance transparency. This involves using polishing oil or specialized techniques to eliminate surface imperfections.

Curing: UV curing is necessary for SLA prints to maximize strength and stability. Prints are cured using UV light in a curing chamber or specific device.

How SLA stacks up against other 3D printing technologies

| Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|

| FDM | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 100-300μm | 2.0 mm (0.0787'') |

| Industrial FDM | ± 0.25% with a lower limit: ± 0.25 mm (± 0.010") | High level of repeatability, engineering grade materials | 406 x 355 x 406 mm (15.98” x 13.97” x 15.98") | 100-330μm | 2.0 mm (0.0787'') |

| Prototyping SLA | ± 0.5% with a lower limit of ± 0.15 mm (± 0.006") | Smooth surface finish, fine feature details | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") | 50-100μm | 0.2 mm (0.00787'') |

| Industrial SLA | ± 0.2% with a lower limit of ± 0.127 mm (±0.005") | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm (19.68" x 19.68" x 19.68") | 50-100μm | 0.2 mm (0.00787'') |

| SLS | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) | Design flexibility, supports not required | 395 x 500 x 395 mm (15.53" x 19.68" x 15.53") | 100μm | 0.5 mm (0.0196”) |

| MJF | ± 0.3% with a lower limit on ± 0.3 mm (0.012'') | Design flexibility, supports not required | 380 x 285 x 380 mm (14.9'' x 11.2'' x 14.9'') | 80μm | 0.5 mm (0.0196”) |

We have high standards for SLA 3D printing

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to the V1 Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

- Parts are fully cured to material manufacturer specifications before shipping.

- Hollow sections are drained of excess resin.

- ll support material is removed and support nibs must be sanded smooth.

Advantages and drawbacks of SLA 3D printing

Advantages

- High Precision: SLA 3D printing offers excellent dimensional accuracy and high-resolution printing, making it suitable for applications that require intricate details and fine features.

- Smooth Surface Finish: SLA prints typically have a smooth and polished surface finish, reducing the need for extensive post-processing and providing a visually appealing final product.

- Wide Material Compatibility: SLA printers can work with a variety of resin materials, including those with specific properties such as transparency, flexibility, or high temperature resistance, allowing for a broad range of applications.

- Support Structures: SLA printers can generate support structures that can be easily removed after printing, enabling the production of complex geometries and overhangs without compromising the quality of the final print.

- Quick Printing Speed: SLA 3D printers can produce prints relatively quickly compared to other 3D printing technologies, thanks to their ability to cure entire layers at once.

Drawbacks

- Limited Build Volume: SLA printers often have smaller build volumes compared to other 3D printing technologies, which can restrict the size of the objects that can be printed.

- Material Handling and Safety: SLA resin materials used in the printing process can be messy and require careful handling and storage. Additionally, some resins may have safety considerations due to their chemical properties, requiring proper ventilation and personal protective equipment.

- Post-Processing Requirements: SLA prints typically require post-processing steps such as support removal, cleaning, and curing, which add additional time and effort to the printing process.

- Material Cost: SLA resin materials can be more expensive compared to filament materials used in other 3D printing technologies, making the overall cost of SLA printing higher.

- Limited Mechanical Strength: While SLA prints offer high accuracy and smooth surface finish, they may have lower mechanical strength compared to prints made with other 3D printing technologies like FDM (Fused Deposition Modeling).

Design Guidelines for SLA 3D Printing

This table summarises the recommended and technically feasible values for the most common features of SLA 3D printed parts.

| Feature | Recommended size |

|---|---|

| Unsupported walls | 1.0 mm (0.0393 in) |

| Supported walls | 0.5 mm (0.0197 in) |

| Minimum feature size | 0.2 mm (0.00787 in) |

| Minimum hole diameter | 0.5 mm (0.0197 in) |

| Minimum escape hole diameter | 4.0 mm (0.157 in) |

Our other 3D printing processes

FDM

Fast & affordable prototyping

- Dimensional accuracy of ± 0.05% with a lower limit: ± 0.05 mm

- Lead times from 1 business day

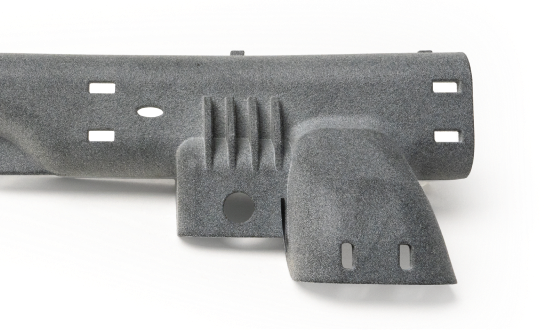

SLS

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit of ± 0.3 mm (± 0.0118")

MJF

Functional prototyping & low-run production

Dimensional accuracy of ± 0.3% with a lower limit on ± 0.3 mm

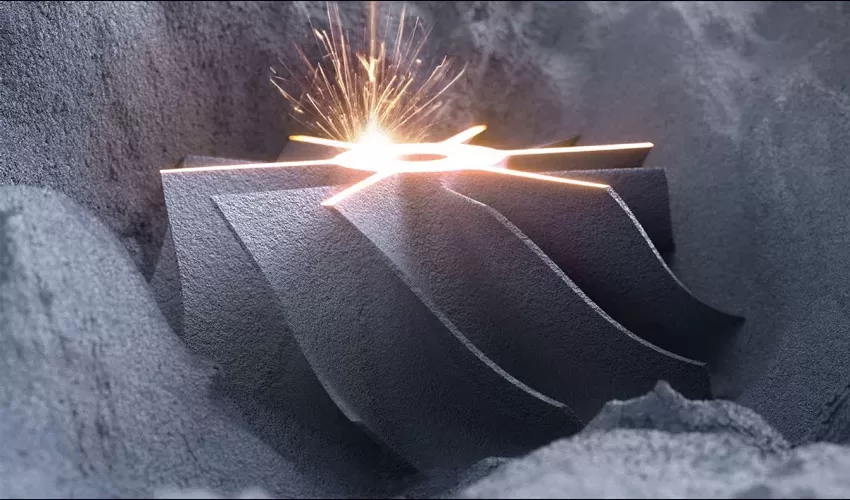

SLM

High-precision metal manufacturing

- Dimensional accuracy of ± 0.1% with a lower limit: ± 0.1 mm

- Suitable for complex and detailed metal parts

- Lead times from 2-3 business days