Revolutionize Automotive Components with Advanced 3D Printing Solutions

Experience a new era of automotive manufacturing with our cutting-edge 3D printing solutions. Unlock the full potential of your automotive components with the perfect blend of precision, complexity, high-strength materials, and intellectual property protection.

The manufacturing of automotive parts is accelerated with V1

V1 enables expedited access to the road without sacrificing design or quality. Our instant quoting platform and specialized supplier network enhance your supply chains and provide you with customized parts for all your prototyping, research and development, validation, and full-scale manufacturing needs. Achieve your targets faster and never miss innovation deadlines with V1's cutting-edge capabilities and extensive capacity.

Certified for automotive manufacturing

V1 is ISO 9001 certified and our suppliers have industrial certifications.

- ISO 9001

- IATF16949

- ISO 13458

- ISO 14001

- ISO TS16949

Thorough quality documentation

Receive validation reports to guarantee the highest quality and compliance.

- Coordinate Measuring Machine Inspection Report

- Complete Dimensional Inspections

- Reports on material testing

- Certificates of materials

- Conformance certificates

- Initial Article Inspections

Highest quality standards

We use a rigorous set of protocols and procedures to maintain quality.

- Special tooling

- Sample size inspection

- Dimensional checks with calibrated equipment

- Review of all quality documentation and industry certifications

- Full IP protections on the platform and within the network

Local sourcing speeds up automotive manufacturing processes

Local sourcing for CNC machining is now available in the EU and US. Our local networks have expanded to provide custom parts more quickly within your custom clearance zones. Our manufacturing partners send parts directly to you with V1 Local, which results in fewer logistical hurdles and faster delivery times.

Quickly Manufactured Automotive Prototypes

Prototyping is essential in the development of automotive technology, and it is inefficient to wait for parts during this phase. Our platform and project teams can provide prompt quotes and deliver parts within days, whether you require a few complex components or several thousand. We can quickly adjust from prototyping to producing small batches and provide substitute parts for First Off Tools (FOTs) when a serial supplier is still being sought.

How automotive companies use V1

- Prototyping

- Intermediary & replacement parts

- Autonomous driving systems

- Electrical vehicles and charging parts

- Manufacturing line jigs & fixtures

- E-bikes and scooters

- Commercial & utility vehicle parts

- Jigs & fixtures

- EV battery testing components

- Parts for resurrecting older technologies

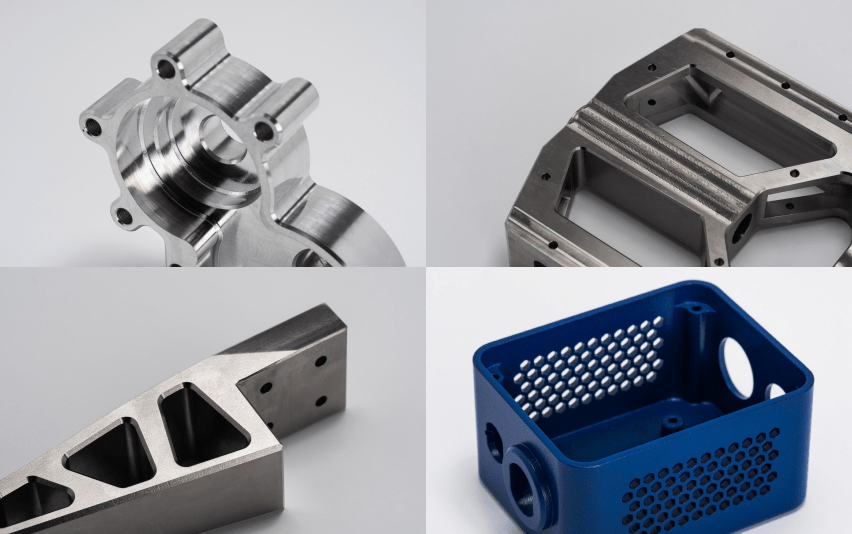

Automotive manufacturing capabilities

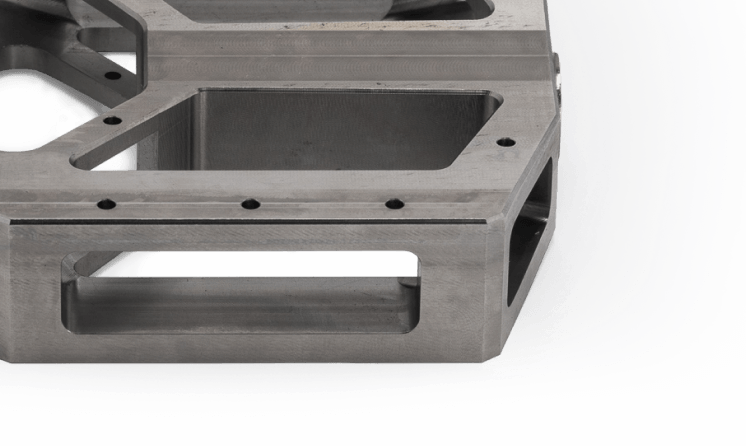

We possess state-of-the-art equipment and technologies to facilitate automotive manufacturing. Our CNC machining centers are capable of accurately fabricating multiple metal parts, including engine components, drivetrain systems, and body structures, while satisfying high precision requirements and complex geometries. In addition, we utilise rapid prototyping techniques such as 3D printing for creating prototypes and samples for automotive manufacturing. Our substantial experience in machining enables us to manufacture the metallic and plastic parts required for automotive usage, while our quality system guarantees attention to detail and compliance with specifications at every stage. Our operations are certified to meet pertinent automotive standards, providing us with the confidence to supply dependable and high-quality solutions for automotive manufacturing.

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

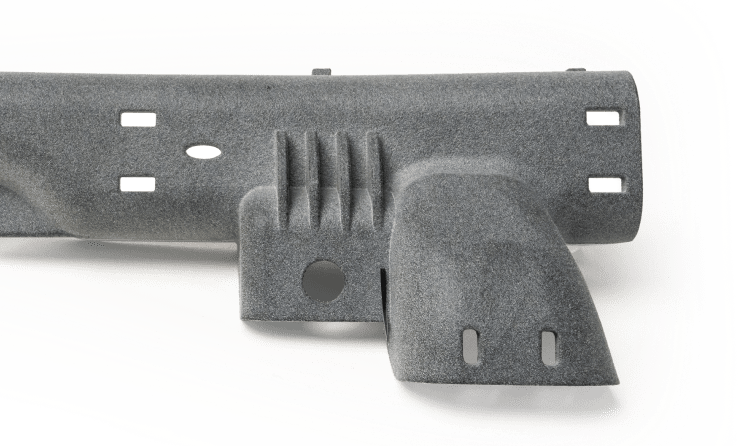

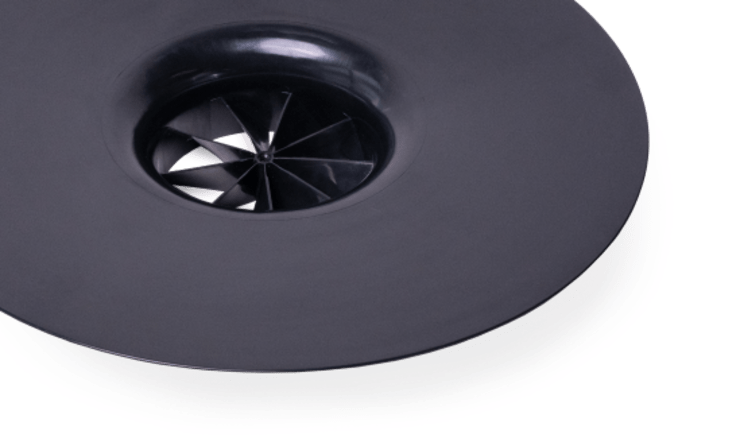

3D printing

FDM, SLA, SLS, MJF、SLM

- ± 0.3% with a lower limit of ± 0.3 mm (± 0.012 in)

- Lead times from 1 business day

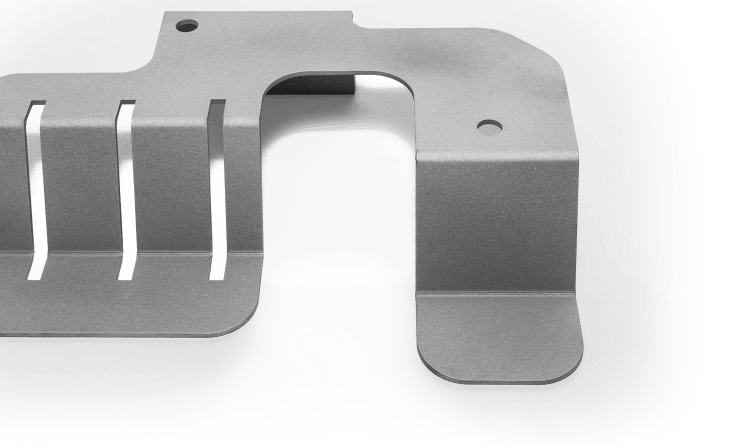

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M parts

Why the automotive industry chooses V1

Specialized network

Get access to cutting-edge capabilities and limitless capacity

Quality assurance

Receive comprehensive documentation with every order

Instant pricing

Get instant quotes with all pricing information upfront

Materials and Surface Treatments for Automotive Parts

We use a variety of materials and surface treatments to offer optimal solutions for automotive parts.

Our metals comprise of carbon steels, stainless steels and aluminum alloys, tailored to the specifications of automakers. In addition, we offer surface treatments like plating, coatings, and modifications to enhance corrosion resistance, wear resistance, and reduce friction. Our coatings are tailored to suit automotive environments.

We meet the high standards for automobile components by offering a wide range of materials and finishing capabilities. Our engineers offer consulting on material selection and finishing to optimize solutions for your automotive components.

Materials for automotive applications

Choose from a wide selection of industrial-grade materials

Available steel options include mild steel and stainless steel variants such as 304/304L, 316/316L, 430, 301, 4140, 4340 and Tool Steels

Titanium grades 1, 2, and 5 available

Aluminium: 6061-T6, 6063, 5052, 5083-H111, 2017, 7075-T651

Thermoplastic materials: Polyethylene (PE), Polypropylene (PP), Polycarbonate (PC) and ABS.

Commodity polymers: Polyethylene terephthalate (PET) and Polyvinyl chloride (PVC).

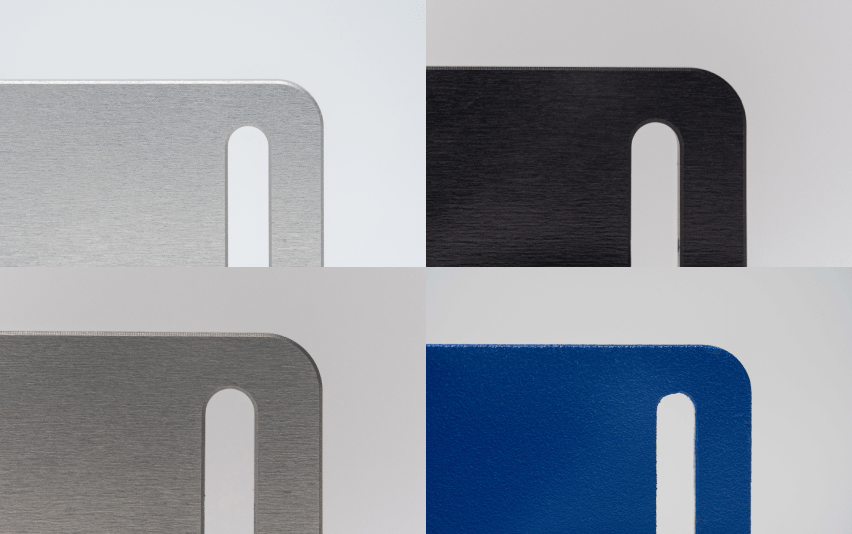

Surface Finishes for Automotive Parts

Choose from these finishes to protect your parts

Anodisation

Powder Coating Treatment

Electroless nickel plating

Polishing

Installation of inserts

Thermal treatment

Passivation

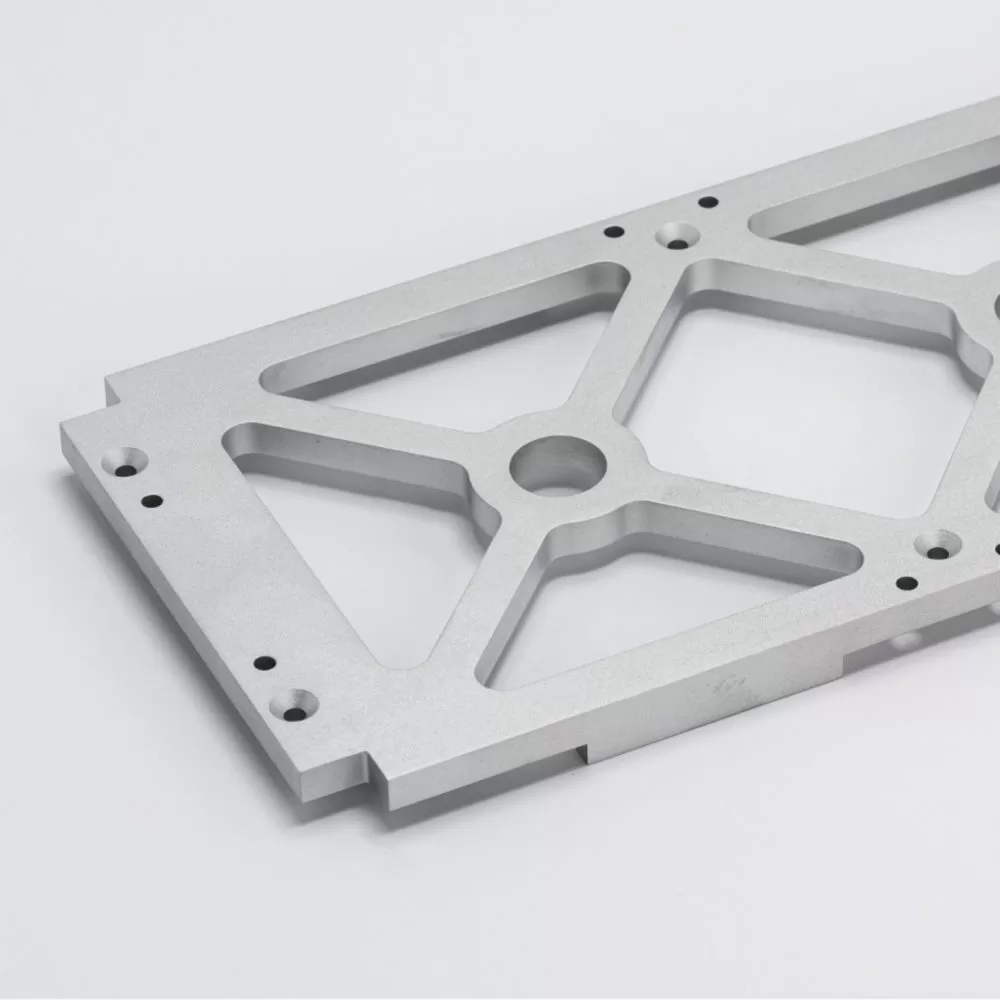

Automobile Parts Gallery

Assisting automotive companies in innovation through V1

We are able to produce complex geometries using state-of-the-art processes

Our manufacturing partners are capable of achieving an incredible level of geometric complexity. We are capable of producing components with exceptional mechanical and cosmetic properties no matter how complex your design is. Our network is equipped with the latest technologies such as 3D printing and Computer Numeric Control (CNC), including 5-axis machines and industrial Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) printers to produce rapid prototypes as well as small batches of production parts with ease.

Save a considerable amount of time with immediate price quoting and design assistance

When it comes to innovating quickly and moving projects from the factory to the road, time is almost never on your side. Avoid waiting for multiple weeks to receive quotations by utilizing our platform, which provides instantaneous pricing and advanced DFM (Design for Manufacturability) analysis. Compare quotations effortlessly and accelerate your parts' production so that you remain aligned with the automotive revolution. V1 offers a comprehensive solution whether you require tooling equipment for testing, a single part for releasing a fleet of vehicles or to update your technologies to meet the electrification demands of the automotive industry.

Collaborate with top-tier V1 mechanics

Our experienced team of automotive engineers and mechanics is ready to assist you in developing innovative products and keeping your project on track. At V1, project teams work in conjunction with our instant quoting and DFM tools to design customized production plans tailored to your specific requirements. We understand how to help your shop save time and effort while optimizing part usage across all aspects of the automotive industry. As automotive industry experts, we have firsthand experience dealing with even the smallest issues that can cause significant delays. Our objective at V1 is to ensure a smooth transition from prototyping to delivering your product to your customer's driveway.

FAQ's

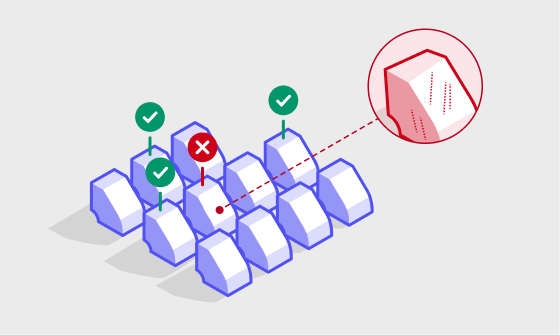

We conduct comprehensive checks of each manufacturing partner (MP) during the onboarding process and carry out audits of their processes and certifications every two years. To procure parts from certified manufacturers, you may specify the requirements on the platform or get in touch with us at 3dprinting@v-1.com. We will match your designs with the most appropriate supplier.

Our platform guarantees the security and encryption of all customer data and supplier interactions. Digital models and drawings are safely stored on European-based AWS servers. Our Manufacturing Partner Agreement is mandatory for MPs to sign as part of their onboarding process, committing them to the confidentiality of customer data. Our General Terms of Sale prohibit orders which infringe on copyrights, patents, design rights, trademarks, trade secrets, or any other type of intellectual property rights.

One of the reasons engineers use V1 is that we take on all the risks for you. In case your parts do not meet the required specifications, you may file a dispute claim and we will either remake the components or refund your order. For further details on how we manage disputes, please contact our Customer Success Team. At the same time, we generate non-conformity reports for parts that fail to meet all requirements and offer follow-up with manufacturers, including root cause analysis and rapid corrective actions.

To obtain parts made from specialized materials that are not included on our site or platform, you may submit a request to your account manager or contact us at 3dprinting@v-1.com. Our supplier network has access to a vast range of materials, enabling us to find a manufacturing partner to fulfill most of your requests.