Mold Manufacturing Service

With 20 years of experience, we are your trusted injection moulding specialists. We offer complete solutions for high-precision, quality-assured moulds, from design to delivery.

V1 Mold Manufacturing Capability

V1 leverages decades of industry expertise and cutting-edge equipment to deliver high-precision injection molds with quality and speed. Our experienced engineering team handles everything from 3D modeling and mold flow analysis to CNC machining and polishing. Using the latest CAD/CAM software, we optimize mold design to avoid defects and shorten cycle times. Our CNC machines enable tight tolerances down to 0.005mm for complex mold geometries. We incorporate high-strength steels and alloys and utilize premium mold components to ensure durability and longevity. Stringent quality control and comprehensive testing validate mold performance before delivery. With proficiencies across a wide range of part sizes and industry applications, V1 has the capabilities to manufacture molds that meet your exact specifications.

Production of serial tools

We have a professional engineering team and advanced equipment, which enables us to undertake mass production of various plastic injection moulds, ensuring high precision and quality.

Production of plastic parts

We can quickly produce plastic injection moulded prototypes to meet product design verification and low-volume production requirements.

Moldflow and warping analysis

We use advanced software to simulate the filling of the mould to help optimise the product design and to predict and reduce deformation.

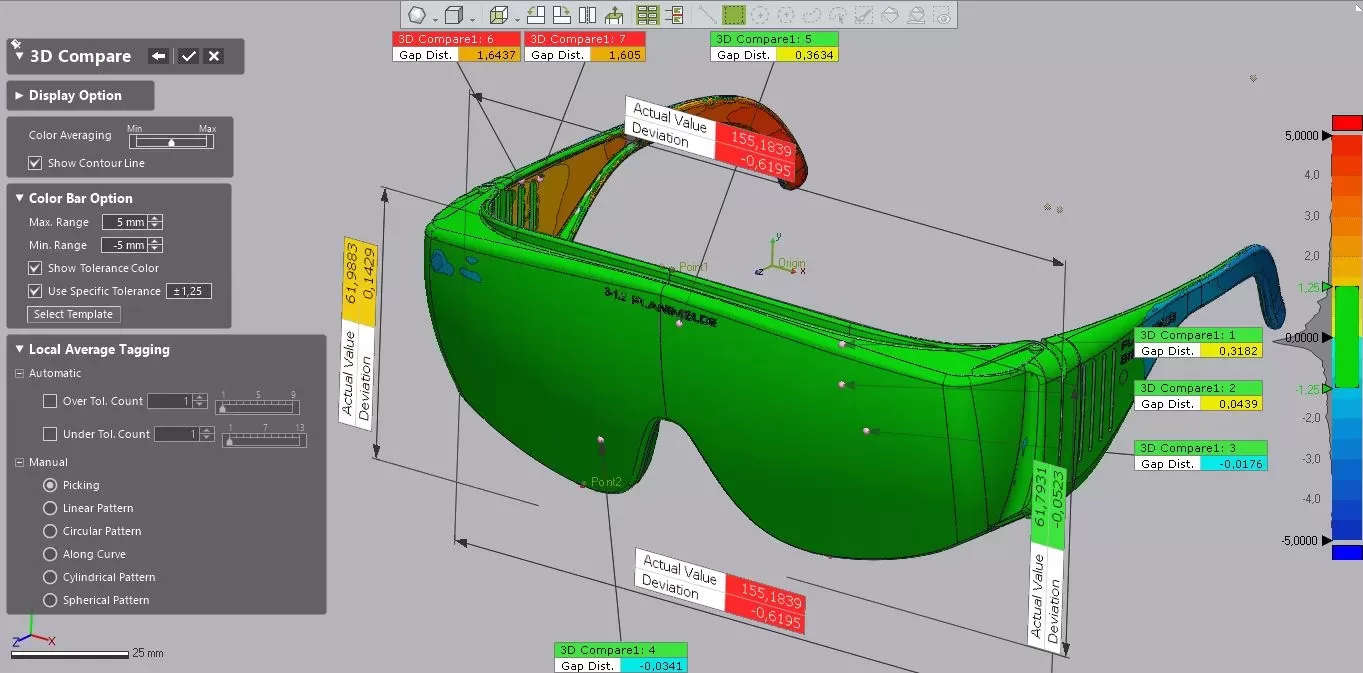

Tools and plastic parts metrology

We provide accurate dimensional inspection services for tooling and plastic parts to ensure quality standards are met.

Full range of mould making equipment to meet all needs

We are equipped with a full range of mould making equipment to meet all types of mould making and repair requirements. Whether it is the manufacture of brand new moulds or the maintenance and refurbishment of existing moulds, our equipment and techniques are up to the task. We have advanced CNC machining centres, wire cutting machines, wire erosion machines, etc. to ensure high precision moulds through accurate CNC machining. We also have the capability for mould design and mould flow analysis to help optimise mould solutions. If you have any mould manufacturing or refurbishment needs, please contact us. We are confident that we can provide professional, high quality solutions.

CNC

Vertical Machining Center

2 Ingersoll High Speed Eagle V5– 5 axes – 42.000 rpm

1 DMG Mori DMU 80P Duo Block – 5 axes – 24.000 rpm

1 Mikron HPM 1150 – 5 axes – 24.000 rpm

2 Mori Seiki NV500 – 3 axes – 20.000 rpm

1 Mori Seiki SVD403 – 3 axes – 20.000 rpm

1 Mori Seiki SV 500 – 3 axes – 20.000 rpm

1 Eumach LBM1500 – 3 axes – 18.000 rpm

1 Eumach LBM2000 – 3 axes – 18.000 rpm

1 Mikron VCE 1600 PRO – 3 axes – 10.000 rpm

Micro-Drilling

1 Agie Charmilles Drill 20

EDM Machine with handling

1 Ops-Ingersoll Gantry Eagle 800 + MultiChange Light

1 Ops-Ingersoll Gantry Eagle 500 + MultiChange Light

EDM Machine

1 Agie Charmilles FO 550 SP

1 Agie Advance

1 Charmilles Roboform 200

Wire Cut EDM Machine

1 Agie Charmilles Cut 30P

1 Agie Charmilles Cut 550P

Surface Grinder

1 Jones & Shipman Techmaster 634 Easy

Turning Lathe

1 Harrison Alpha Plus 460 S

Drilling Centre

1 HETO 1000 Compact

CAD CAM

11 workstations with several softwares

Cimatron (Design and Milling)

TopSolid

PowerMill

Progecad

PowerShape

Fikus

LeMoine

Simulation Software

CADMOULD

CONVENTIONAL

Surface Grinder

1 Lipemec P400

1 Mater 15-8

1 Jones Shipman 540H

1 Aba

2 Monoprecis

Fitting Press

1 Millutensil Mil123

QUALITY CONTROL

3D Co-ordinate Measuring Machine

1 WENZEL SF87

1 DEA Mistral 100705

Hardness Meter

1 Emcotest

Profile Projector

1 Mitutoyo PH-350-H

Digital Profile Projector

1 TESA V300GL

3D Scan

1 CRONOS Camera 3,1Mpix

1 FARO ARM Quantum w/Scanner Laser Faro BLU HD

INJECTION UNIT

Injection Machines

BATTENFELD EcoPower 180T

ENGEL Vitory 500 (2K)

ENGEL Victory 300

ENGEL Victory 160

ENGEL e-Motion 110T (All Electric)

Cleanroom ISO6

Robots

All machines equipped with Viper and Wittmann Robots

Temp. Control Units

2 Tool Temp 137B/BP

2 Tool Temp TT 168EC

2 YUDO Bold312IC32C

International Manufacturing

Quality and Efficiency Combined

Benefit from our global manufacturing approach. By leveraging both overseas and Dongguan, China factories, we deliver top-quality results quickly. Our rigorous quality standards ensure consistency throughout the process, with final work completed overseas. Enjoy the cost advantages of China alongside reliable local manufacturing. Experience high quality, competitive costs, and fast delivery. Our dual-facility approach is the ideal solution for your needs.

Our Other Manufacturing Capabilities

In addition to moulding and tooling, we offer a wide range of manufacturing capabilities to meet your product needs. Our metal fabrication facility allows us to produce high precision CNC machined parts in a variety of metals. We also offer sheet metal fabrication and welding services for steel and aluminium components. For surface treatment we offer anodising, powder coating, plating, painting and other finishing services. Our workshop is equipped to produce functional prototypes, models and low volume production runs. We also partner with a network of qualified suppliers for secondary processes such as electronics assembly, plastic injection moulding and die casting. Our experienced engineers work to find the ideal production methods for your products, maximising quality, cost and delivery. Discover how our comprehensive manufacturing solutions can turn your vision into reality.

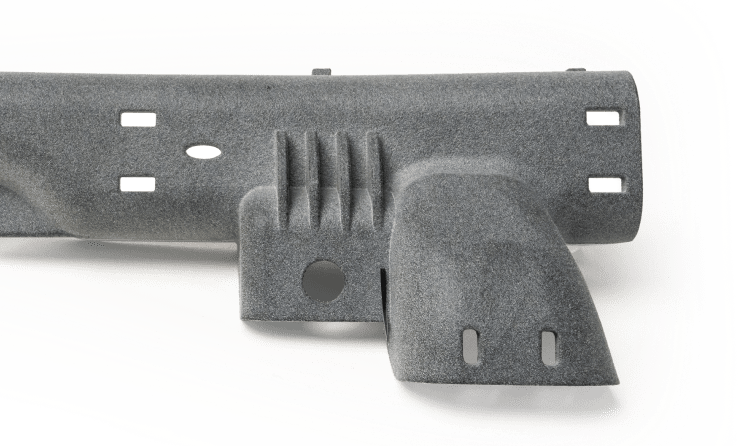

3D printing

FDM, SLA, SLS, MJF、SLM

- 25+ plastics & 35+ colors

- ±0.5% dimensional accuracy with a lower limit down to ±0.0059 in (0.15 mm)

- Lead times from 1 business day

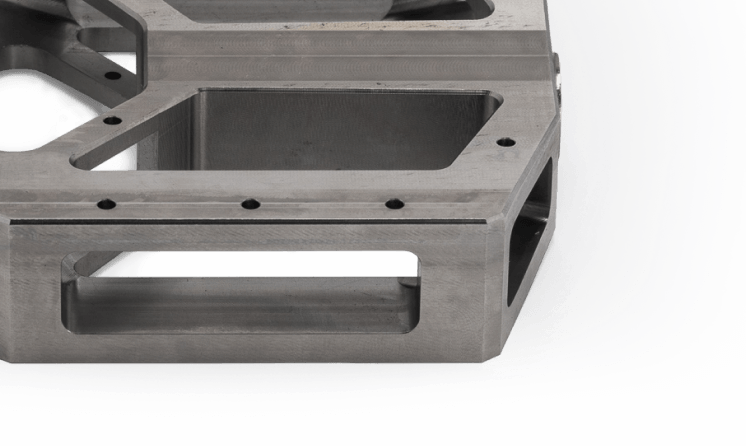

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

- 50+ metals and plastics & 10 surface finishes

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

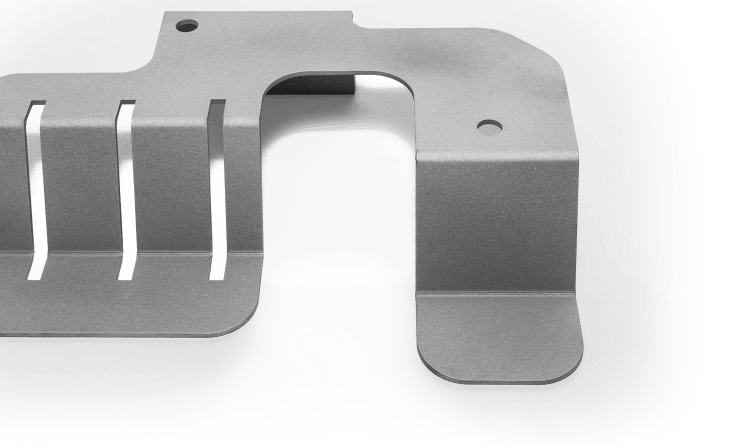

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

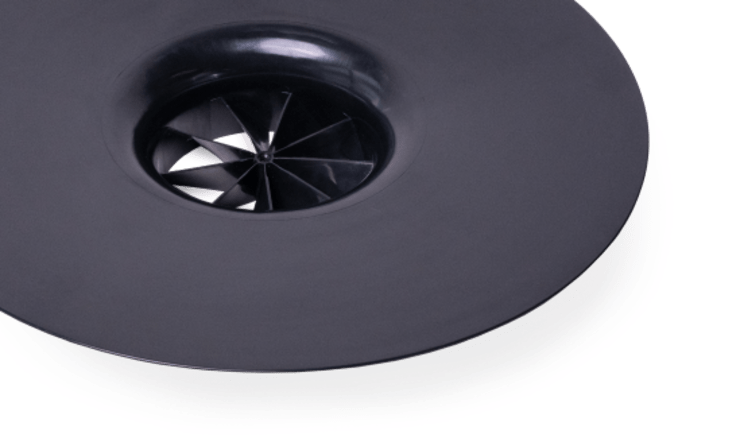

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M parts