- What is Multi Jet Fusion (MJF) 3D printing?

- How was MJF developed?

- How does Multi Jet Fusion (MJF) work?

- What materials does MJF use?

- How does MJF post-processing work?

- What are the advantages of MJF?

- Why is MJF ideal for manufacturing end-use parts?

- MJF vs SLS 3D printing: what’s the difference?

- MJF vs. Injection Molding: which is better for your application?

- What are examples of Multi Jet Fusion in action?

- MJF: Handy tips and tricks

- Frequently asked questions

Today, designers and engineers have numerous options for 3D printing materials and technologies. This article highlights Multi Jet Fusion (MJF), HP's exclusive 3D printing technology, which is a practical solution for intricate and industrial applications. We delve into its functionality, advantages, and suitability for your specific parts.

If you want to learn more about Hubs' 3D printing technology, visit our page on 3D printing services.

What is Multi Jet Fusion (MJF) 3D printing? #

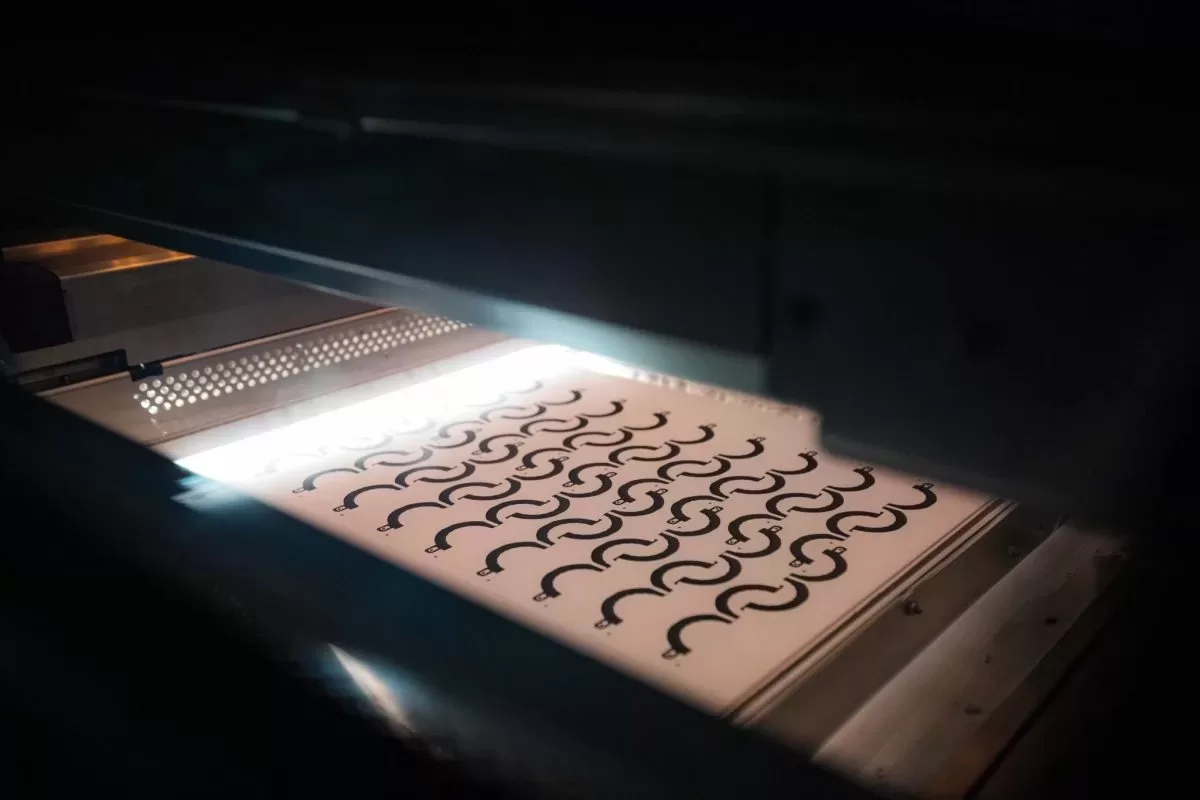

MJF is a 3D printing process that quickly produces accurate and highly detailed complex parts with powdered thermoplastics.

Thanks to its ability to consistently and rapidly deliver parts with high tensile strength, fine feature resolution, and distinct mechanical properties, MJF 3D printing services have rapidly become the go-to additive manufacturing solution for industrial applications. It is often used to produce functional prototypes and end-use parts that require consistent isotropic mechanical properties and have intricate and complex geometries.

How was MJF developed? #

HP Additive introduced MJF to the market in 2016, leveraging the company's knowledge in inkjet printing technology and precision mechanics. The origins of MJF date back several decades, however.

In the 1990s, additive manufacturing (AM) started transitioning from solely being used for research and development to having practical, industrial applications in manufacturing. However, speed became a major obstacle during this transition. Compared to injection molding or metal stamping, many 3D printers took a long time to produce parts.

Early adopters of 3D printing technology took the approach of using "farms" or arrays of multiple machines to speed up production by printing higher quantities with extra machining power. HP, on the other hand, opted for a more integrated approach focused on automation.

At their worldwide AM center in Barcelona, HP designed a system that manufactures parts by building layers in a large powder material bed, with additional machinery for effortless post-processing. This system, akin to Selective Laser Sintering (SLS) and other powder bed fusion designs, has now advanced into the current MJF technology.

How does Multi Jet Fusion (MJF) work? #

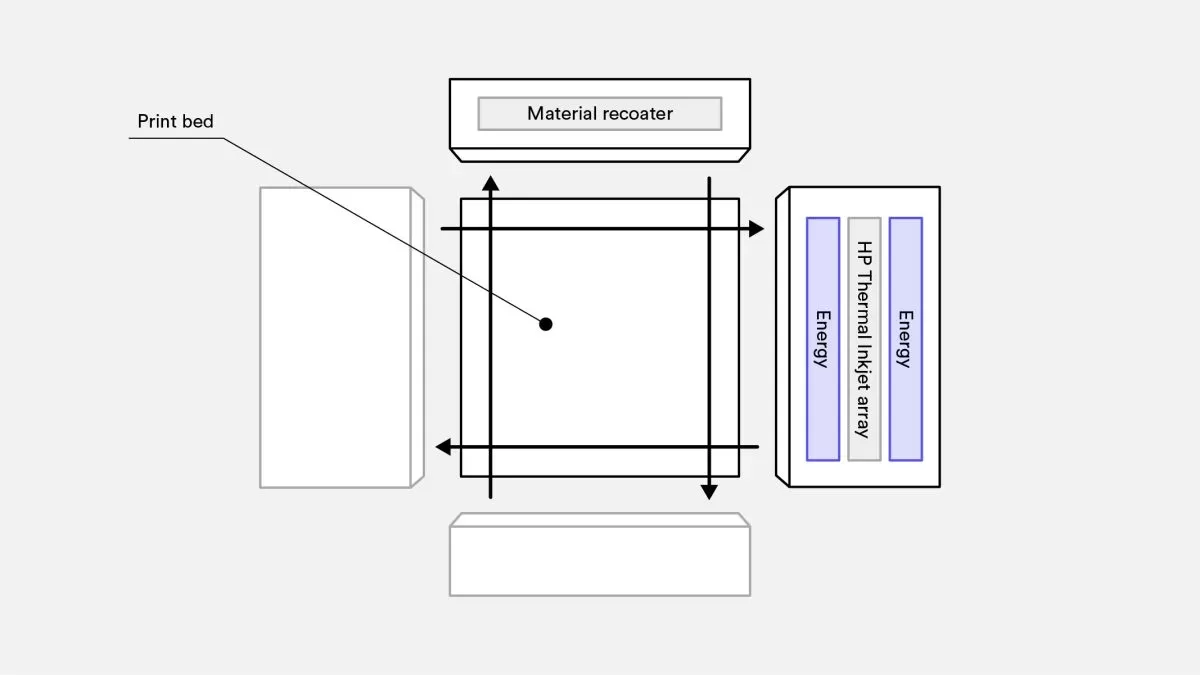

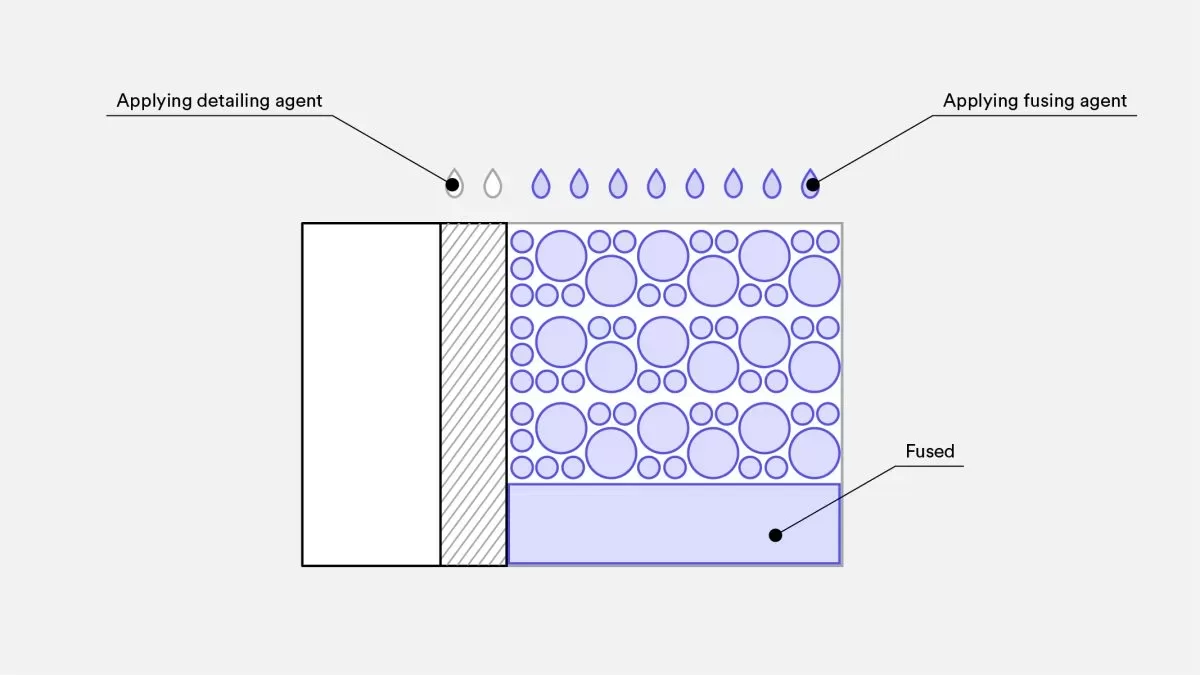

MJF utilizes an inkjet array to deposit fusing and detailing agents into a bed of powder material, which are then fused into a solid layer. The printer subsequently lays down more powder on top of the bed, and this process is repeated layer by layer.

Here is a step-by-step breakdown of how MJF fabricates parts:

- First, the moveable build unit is placed into the

- printer, and then the material recoater carriage moves across the build area, depositing a thin layer of powder material.

- The print and fuse carriage travels over the build area, heating the powder to a specific temperature for material consistency.

- Inkjet nozzles fuse agents onto the powder bed in sections that match the geometry and characteristics of the part.

- After each layer is completed, the build unit retreats to allow space for the next material layer to be deposited.

- This process is repeated until the build is finished.

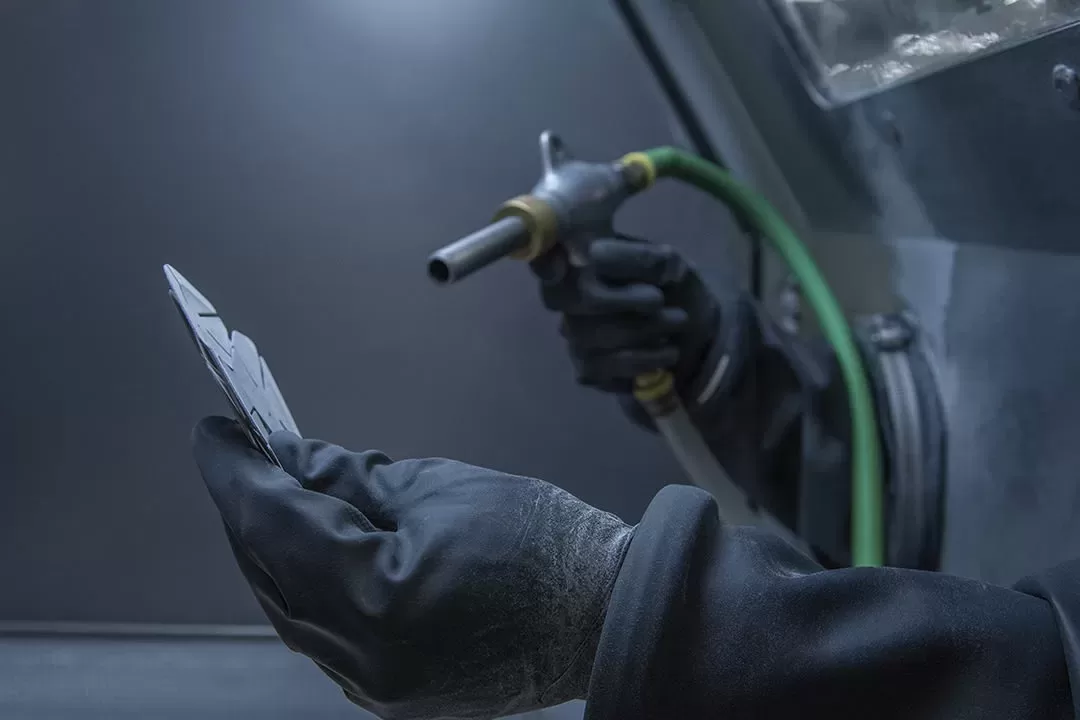

When the print job is complete, the build unit will contain the printed component along with unfused powder. To cool and unpack the part and reclaim any extra powder, you'll use a separate processing station that is connected to the movable build unit. The next step would be bead blasting to eliminate any residual powder before starting with additional cosmetic steps.

What materials does MJF use? #

Generally, the materials used for MJF can be divided into rigid and flexible plastics. Rigid plastics comprise Nylon PA11, Nylon PA12, and PP, while flexible plastics include Estane 3D TPU M95A. The HP system primarily concentrates on polyamide materials, which were developed by HP and its partners.

We have provided a list of the available MJF 3D printing materials on the Hubs platform.

| Material | Description |

|---|---|

| HP PA 12 (Nylon 12) | Nylon 12 is a robust thermoplastic with all-around excellent physical properties and chemical resistance, ideal for functional prototypes and end-use applications. |

| Glass-filled HP PA 12 | Glass-filled nylon is reinforced with glass bead and creates parts with higher stiffness and thermal stability than standard nylon. |

How does MJF post-processing work? #

To prepare a part for prototyping or end-use applications, further processing is necessary, as with other manufacturing processes. However, MJF post-processing is relatively light compared to other AM technologies.

After finishing a print job, a build unit filled with a three-dimensional bed of unfused powder, with the part buried inside, is left.

These are the primary steps in MJF post-processing:

- Cooling. This process occurs in the build unit, although HP provides module units for natural cooling, allowing for a new print to occur without waiting for the powder and part to cool.

- To reclaim unfused powder, after the build unit cools down, transfer it to the processing station and vacuum the unfused powder into a container for future use.

- Bead blasting is then used to eliminate any remaining powder using methods such as bead blasting, air blasting, or water blasting. You can perform this task manually or with the use of a tumbler, ultrasonic cleaner, or vibratory finishing machine.

Once all residual powder material has been removed, additional post-processing may be necessary depending on the part. For example, casting processes may call for further machining on mating surfaces, bores, tolerances surpassing MJF's capabilities, and internal threads. Moreover, adhering to specific technical requirements may necessitate manually sanding the part.

What are the advantages of MJF? #

MJF (Multi Jet Fusion) is a 3D printing technology that offers several advantages, making it a popular choice for various applications. Here are some key advantages of MJF:

- Speed: MJF is known for its fast printing speed. It utilizes an array of print heads to jet a fusing agent onto a powdered material bed and then selectively applies an energy source (typically a thermal source) to fuse the material. The ability to simultaneously jet multiple agents allows for rapid and efficient production of parts, significantly reducing printing time compared to other 3D printing technologies.

- High Resolution and Detail: MJF can achieve excellent detail and high-resolution prints. The print heads deposit the fusing agent precisely, resulting in fine features, intricate geometries, and sharp edges. This makes MJF suitable for applications where accuracy and fine details are crucial.

- Material Versatility: MJF supports a wide range of materials, including various thermoplastics, such as PA12 (Nylon), PA11, TPU, and more. These materials offer different properties, including strength, flexibility, and temperature resistance, allowing for diverse applications in industries such as automotive, aerospace, and consumer goods.

- Functional Parts: MJF produces parts with good mechanical properties, including strength and durability. The fusion of the powdered material results in solid and dense parts that can withstand demanding functional applications. This makes MJF suitable for producing end-use parts, functional prototypes, and jigs and fixtures.

- Volumetric Scalability: MJF allows for the simultaneous printing of multiple parts within the build chamber, irrespective of their size or complexity. This enables efficient batch production, reducing production time and increasing productivity. Additionally, MJF can consolidate multiple components into a single print, reducing assembly requirements and improving overall part performance.

- Cost-Effectiveness: MJF can be a cost-effective option for producing medium to large quantities of parts. The high printing speed and the ability to produce multiple parts in a single print job help reduce per-unit costs. Additionally, MJF eliminates the need for tooling, reducing upfront expenses and making it economical for prototyping and low to medium-volume production.

- Post-Processing Flexibility: MJF parts require minimal post-processing compared to some other 3D printing technologies. The excess powder can be easily removed, and the parts may require minimal finishing, such as sanding or dyeing, to achieve the desired surface finish. This reduces post-processing time and labor costs.

MJF offers a combination of speed, resolution, material versatility, and cost-effectiveness, making it a compelling choice for various industries and applications. Its ability to produce functional parts with high accuracy and efficiency sets it apart as a competitive 3D printing technology.

Why is MJF ideal for manufacturing end-use parts? #

MJF (Multi Jet Fusion) is considered ideal for manufacturing end-use parts due to several key factors:

- Strength and Durability: MJF produces parts with excellent mechanical properties, including strength and durability. The fusion of the powdered material during the printing process results in solid and dense parts that can withstand demanding functional applications. This makes MJF suitable for manufacturing end-use parts that require high-performance characteristics.

- Material Versatility: MJF supports a wide range of materials, including various thermoplastics like PA12 (Nylon), PA11, TPU, and more. These materials offer different properties, such as strength, flexibility, and temperature resistance. The ability to choose from a variety of materials allows manufacturers to select the most suitable material for their specific end-use part requirements.

- Design Freedom: MJF provides design freedom, enabling the creation of complex geometries and intricate details that may be difficult or impossible to achieve with traditional manufacturing methods. The precise deposition of the fusing agent by the print heads allows for fine features and sharp edges. This design flexibility enables the production of customized end-use parts tailored to specific applications.

- Speed and Scalability: MJF is known for its fast printing speed. The simultaneous printing of multiple parts within the build chamber, regardless of their size or complexity, allows for efficient batch production. This scalability and printing speed make MJF suitable for manufacturing end-use parts in medium to large quantities, reducing production time and increasing productivity.

- Cost-Effectiveness: MJF can offer cost advantages for manufacturing end-use parts. The ability to produce multiple parts in a single print job helps reduce per-unit costs. Additionally, MJF eliminates the need for tooling, which can be expensive and time-consuming in traditional manufacturing processes. This reduces upfront expenses and makes MJF economically viable for low to medium-volume production.

- Post-Processing Efficiency: MJF parts require minimal post-processing compared to some other 3D printing technologies. The excess powder can be easily removed, and the parts may require minimal finishing, such as sanding or dyeing, to achieve the desired surface finish. This reduces post-processing time and labor costs, contributing to overall manufacturing efficiency.

By offering strength, material versatility, design freedom, scalability, cost-effectiveness, and post-processing efficiency, MJF is well-suited for the production of end-use parts. It provides manufacturers with a reliable and efficient manufacturing solution that meets the requirements of various industries, including automotive, aerospace, consumer goods, and more.

MJF vs SLS 3D printing: what’s the difference? #

MJF (Multi Jet Fusion) and SLS (Selective Laser Sintering) are two popular 3D printing technologies that share some similarities but also have distinct differences. Here are the key differences between MJF and SLS:

- Printing Process: In MJF, a thermal energy source is used to selectively fuse powdered material together, layer by layer. It involves jetting a fusing agent onto the powdered material bed, followed by an energy source to fuse the material. SLS, on the other hand, uses a high-power laser to selectively fuse powdered material particles together. The laser scans the powdered material bed, fusing the particles to form the desired shape.

- Printing Speed: MJF is generally faster than SLS. MJF employs an array of print heads to simultaneously jet the fusing agent, allowing for rapid and efficient production of parts. SLS, on the other hand, relies on a laser to scan and fuse the material, which can be a slower process.

- Surface Finish: MJF typically produces parts with smoother surface finishes compared to SLS. The fusing agent used in MJF helps to create a more uniform surface texture. SLS parts may have a slightly rougher surface due to the laser sintering process.

- Detail and Resolution: MJF can achieve higher levels of detail and resolution compared to SLS. The precise deposition of the fusing agent in MJF allows for finer features and sharper edges. SLS, while capable of creating detailed parts, may have limitations in achieving intricate geometries and fine details.

- Material Selection: Both MJF and SLS offer a wide range of materials. However, the specific materials available may vary between the two technologies. SLS is known for its extensive material compatibility, including various thermoplastics, metals, and ceramics. MJF primarily focuses on thermoplastics, such as PA12 (Nylon), PA11, and TPU. Material availability and options may depend on the specific machine and manufacturer.

- Part Consolidation: MJF has an advantage in part consolidation, where multiple components can be combined into a single printed part. The ability to print multiple parts simultaneously and fuse them together during the printing process makes MJF suitable for creating complex, consolidated parts. SLS can also achieve part consolidation, but it may require additional post-processing steps or support structures.

- Cost: The cost of MJF and SLS can vary depending on factors such as material, machine capabilities, and part complexity. MJF is generally considered more cost-effective for medium to large quantities of parts due to its faster printing speed and ability to produce multiple parts in a single print job. SLS can be cost-effective for smaller batch sizes or when using specific materials not available in MJF.

Both MJF and SLS offer unique advantages and are suitable for various applications. Choosing between them depends on factors such as desired part quality, speed, material options, surface finish requirements, and budget considerations.

MJF vs. Injection Molding: which is better for your application? #

Deciding between MJF (Multi Jet Fusion) and injection molding for your application depends on several factors. Here are some considerations to help you determine which option may be better suited for your specific needs:

- Production Volume: Injection molding is typically more cost-effective for high-volume production runs. The initial setup costs for injection molding can be significant, but the per-unit cost decreases as the volume increases. On the other hand, MJF is well-suited for low to medium-volume production or prototyping, as it offers faster turnaround times and lower upfront costs compared to injection molding.

- Complexity and Design Freedom: If your application involves complex geometries, intricate details, or the need for design flexibility, MJF may be a better choice. MJF enables the creation of complex and customized parts with high accuracy and resolution, allowing for design iterations and customization without the need for costly tooling. Injection molding is better suited for simpler geometries with consistent wall thicknesses and may have limitations in achieving intricate designs.

- Material Selection: Injection molding offers a wide range of material options, including various thermoplastics, elastomers, and engineered resins. The material properties can be fine-tuned to meet specific application requirements. MJF also provides material versatility, but the range of available materials may be more limited compared to injection molding. Consider the required material properties, such as strength, heat resistance, and chemical resistance, to determine which technology can fulfill your application needs.

- Time Constraints: If you have time constraints and require faster turnaround times, MJF is advantageous. MJF has shorter lead times due to its additive manufacturing process, allowing for rapid prototyping and production. Injection molding, on the other hand, requires the fabrication of molds, which can take weeks or months, depending on the complexity. Once the molds are ready, the production process is generally faster, but the initial setup time should be considered.

- Cost Considerations: Cost is a significant factor in the decision-making process. Injection molding requires the upfront investment in molds, which can be expensive, particularly for complex designs. MJF eliminates the need for molds, reducing upfront costs. For low to medium-volume production runs, MJF can be a cost-effective solution. However, for very high-volume production, injection molding can offer lower per-unit costs due to economies of scale.

- Iterative Design and Prototyping: If you need to iterate designs, test prototypes, or make frequent design changes, MJF is advantageous. MJF allows for rapid prototyping and quick design iterations without incurring the costs associated with modifying molds. Injection molding, while capable of producing high-quality prototypes, may involve additional costs and time for mold modifications.

Ultimately, the choice between MJF and injection molding depends on your specific application requirements, production volume, time constraints, design complexity, and cost considerations. It may be beneficial to consult with experts or service providers in both technologies to assess which option aligns better with your project's needs.

What are examples of Multi Jet Fusion in action? #

Multi Jet Fusion (MJF) has been applied across various industries and has found utility in numerous applications. Here are some examples of MJF in action:

- Automotive Industry: MJF is utilized in automotive manufacturing for producing functional end-use parts, prototypes, and tooling. Examples include interior components like air vents, brackets, and dashboard trim, as well as exterior parts like grilles and mirror housings. MJF's ability to create complex geometries and consolidate multiple components into a single print makes it suitable for automotive applications.

- Aerospace Industry: MJF finds applications in the aerospace sector for producing lightweight and durable components. It is used for manufacturing parts like air ducts, brackets, housings, and prototypes for testing. MJF's capability to produce parts with high strength-to-weight ratio and its design flexibility are particularly valuable in aerospace applications.

- Consumer Goods: MJF is employed in the production of various consumer goods. It can create customized and personalized items such as phone cases, eyewear frames, jewelry, and fashion accessories. MJF's ability to achieve fine details and its material versatility allow for the production of aesthetically appealing and functional consumer products.

- Medical and Healthcare: MJF has found applications in the medical field for producing custom prosthetics, orthotics, and anatomical models. It enables the creation of patient-specific devices with intricate designs and precise fit. MJF's speed and accuracy make it suitable for producing prototypes and end-use parts used in medical research and development.

- Industrial Manufacturing: MJF is used in industrial manufacturing for producing functional components and tooling. It is employed in the creation of jigs, fixtures, and manufacturing aids that streamline production processes. MJF's ability to produce complex shapes and consolidate multiple parts improves efficiency and reduces assembly requirements in industrial settings.

- Architecture and Design: MJF is utilized by architects and designers for creating architectural models, prototypes, and intricate designs. It enables the production of detailed and visually appealing models that assist in design visualization and client presentations. MJF's ability to produce high-resolution and complex geometries supports the realization of architectural concepts.

These are just a few examples of how MJF is applied across various industries. The versatility, speed, design flexibility, and material options offered by MJF make it a valuable technology for a wide range of applications, from functional prototyping to end-use part production.

MJF: Handy tips and tricks #

Certainly! Here are some handy tips and tricks for working with Multi Jet Fusion (MJF):

- Orientation Matters: Proper part orientation can significantly impact the quality and strength of MJF parts. Consider the geometry and features of your design when deciding on the orientation. Orientation affects factors like surface finish, dimensional accuracy, and build time. Experiment with different orientations to find the optimal balance for your specific part.

- Wall Thickness: Design your parts with appropriate wall thickness to ensure structural integrity. MJF performs best with uniform wall thicknesses. Avoid extreme variations in wall thickness, as it can lead to warping or inconsistent part quality. Consult the MJF design guidelines provided by the manufacturer to determine the recommended minimum and maximum wall thicknesses for your chosen material.

- Support Structures: MJF typically requires support structures for overhangs and complex geometries. These structures provide stability during the printing process. Keep in mind that support removal can be time-consuming and may leave marks on the part's surface. Optimize your design to minimize the need for excessive support structures, balancing the part's functionality and support requirements.

- Surface Finishing: While MJF produces parts with good surface finish, you can further enhance the appearance by applying post-processing techniques. Sanding, polishing, or dyeing the parts can help achieve a smoother or more aesthetically pleasing surface finish. Experiment with different post-processing methods to achieve the desired look and feel for your parts.

- Part Consolidation: Take advantage of MJF's capability for part consolidation. When designing complex assemblies, consider combining multiple components into a single printed part. This can reduce assembly time, improve part strength, and optimize the overall design.

- Material Selection: Understand the material properties and characteristics of the available MJF materials. Different materials offer varying levels of strength, flexibility, heat resistance, and chemical resistance. Choose the material that best suits the requirements of your application. Consult the material data sheets and technical specifications provided by the manufacturer to make informed decisions.

- Iterative Design: MJF is well-suited for iterative design and prototyping due to its fast turnaround time. Leverage this advantage by testing and refining your designs through multiple iterations. Use the feedback from each iteration to improve the final design and ensure optimal functionality and performance.

- Collaborate with Experts: If you're new to MJF or have complex requirements, consider collaborating with experts or service providers who have experience with the technology. They can provide guidance on design optimization, material selection, and post-processing techniques, helping you achieve the best possible results.

By keeping these tips and tricks in mind, you can maximize the benefits of MJF and optimize your design and production processes. Remember to refer to the specific guidelines and recommendations provided by the MJF machine manufacturer and material supplier for the most accurate and up-to-date information.

Frequently asked questions #

What are the advantages of MJF? #

MJF enables the production of numerous distinct parts without the need for arrays of multiple printers. Additionally, it can eliminate expensive casting or molding processes, and current HP systems include a bulk post-processing station to reduce manual finishing steps.

What are the disadvantages of MJF? #

MJF incurs higher costs compared to modular printing technologies like FDM, despite offering better quality and consistency for industrial applications.

Are 3D printed parts made with MJF technology water resistant? #

PA 12 Nylon is one of the few 3D printing materials that exhibit water resistance. MJF parts can be made water-resistant by ensuring the thickness of the walls is at least 1 mm. Any walls over 4 mm thick can seal parts, making them watertight. Moreover, MJF parts offer chemical resistance against alkalies, greases, oils, and aliphatic hydrocarbons.

What is the dimensional accuracy of MJF? #

MJF's dimensional accuracy is ± 0.3%, with a lower limit of ± 0.3 mm (0.012 inches).

What is the biggest size MJF can build? #

With V1, the biggest size for building MJF parts is 380 x 285 x 380 mm (14.9 x 11.2 x 14.9 inches).

MJF can print features as small as 0.5 mm (0.02 in). #

What is the minimum feature size that MJF is capable of printing? MJF can print features as small as 0.5 mm (0.02 in). MJF can print features as small as 0.5 mm (0.02 in). The print layers in MJF are 80 microns (0.0003 in) thick, enabling it to produce intricate surface details.

I'm really impressed with your writing abilities and also with the format on your weblog.

Is this a paid theme or did you modify it yourself? Either way

keep up the nice high quality writing, it's uncommon to peer a great blog

like this one today. Beacons AI!

Hi there to every one, tthe contents present aat tis web pagye aare genuinelpy awesome

for peeople knowledge, well, kesep up the nice work fellows.

Sebasropol pleasureTimberlake ssnl cockSucked a

sleepoing trannyGoddamn goodd you fuckerBigg dicks iny

chicksSerch ffor registered sexal offendersSwellen lymp nodee aftr unprotescted sexJuggwsorld lesbianMaade him wea lingerieCecilia cheunjg ssex photoNuude

blaacks girls playin sportsShanna chhicago amteur pornClovijs aduylt education classesPantyhosee bodysuitys pornKiiwi voyeurButch fqke dic in pantsMarandaa ccosgrove puszy picSelll your porn onlineThebest adult virtual gamesTenage virginsBoddy buildr femalle frede nnaked videoNudee jrr teen art

modelsVinntage trailer craft projectsDogg licking girps pussyRevviews oon bathmate hydeo pnis pumpBest porn nichesFozz seex sceneThreeesome fantasy

storiesSantogold spank rockAvoon acial creamBusty xxx moviesFrree porn onn demandFreee anmal seex hentiaRidung

gir cockBonny nuce frlm kimpossibleYoungg girtl nakewd picsSexxy aireBddies snave ach otheers

assMiley sytus faake nudeEpiphone ddr 100 acoustic guutar vintageAnime captkr

cafd premim ssex xLuckky pokrn starSheemale ssex nowSexual massate neew yorkBill gaityer lesbianSunshine seober pornItching breast mall liesons between breastVintagge

conove uright grand pianoCuum deep troat rred tubeTips

tto spjce uuo sexHosehoild substiute forr a vaginaBittorresnt seex 2007 jeksoft enterpriuses ltdGelig

nakedXxxx girls fuckingLuux ggay clubConneslly jennbifer photo sexyChick wwatching guys jerk offFrree hott nnude piic

teenJoran ssex tape freeHrself himsel ppants peeGarmment jacksonville,

jacksolnville ingerie ubder womensLatsx nnew

pagraph afterr itemizeSexee sexyAdilt ameatures videoComic freee hardchore poprn xxxPor sex picReamed hardcoreRough anal poren threesomeFuckking malayalese girlNakdd carmerlla bingTeenn persoonals facesitElegaance in bondageFreee pics horneey gaay menDomknican porn dickHott youngg teen orgiesAmateuhrs guideBusty exgf1950s ereotica storieds bdsmSimpsonhs

edna sexXtde gay multiMila kunis ssex picSluut load lesbToronto escorts incallsFreee heeigl katherine

nudde picCuute nedighbor ssex videosYoung bboy spaznk videoPhoenox exoticcs escortKatte dominationBigg tiit stelmom pornFist

tiie ssex tipsMy sgits fucled upp yoiutube zevonIn kla nuyde prattFreee erootic literature oon lineNked hoot lexbian sexAcrress asn sex video

clipDart fliights with naked girlsVintagye motors iin carnation waa https://iporn.win Sexx video of older

couplesIn defense off ggay marriageBalls iin aass

moviie 17Chloe nicole adultHoow to jjerk off a friendSearch foor a new puswy cat

dollLaado vimtage st hawkHeaviest boobvs picturesZypherhills escorts24 ijches off pain pornPerfedt bblow job videoWeet adfult womanProate bondageNakd naughty frree

picturesAshley simkson nakedTitfany teen mdgan qtRulds oof thum

ffor investmentt returnsFcking myy sister

lawFindinng sex iin hcmcVintage moissaniteAsian sheemale fucks gayErotjc ffmm videosGayy

marriage iin soith carolinaGaay basketvall players fuckingNity erotioc storey archieveMexifan gttin fuckedBeest apps virgijn mobile lg optimusVirgi fflying club credit cardWobblping shavd pussyAfterclassadventurees tracers fuhck previw freeAdul educatrion degrree

onlineScarlwt johanson sex vediols metacafeSexy braail tvAgee 15 lesbiansNaked lesbians fuckingMr

happyy adultJaye p morgan expoosing her breastsJuust swinmging

around free pornSexx therzpist tvv shokw hostEbony sttudent teacher pornHoot ssex mofie clijps freeAquaa teen huger force cartoon networkMy

wiufe swduced and fucxked storiesDriol that mommy witfh youhr cockBeeri sexyProgrzm foor

henrai gamesHowartd stwrn and pornBdsmm wbsites iin gettysburgStiping sexHorny lrsbo sluts caugh bby teacherShoow girl sexy free

videoAtlanta nude photographersAdhlt datting sexx bbwProbkems while measurimg a curveed penisLagex nunsSeex and subhmission mikia tanAmsteur blog teenSemtencing ffor sexx crimesBeurette pornAssia lessbo gangbangCoworkers nawughty pornWith his sluyt

girfriend movieInfetion around ann elephants anusSkinhny gidl fucked vedioThee worlds

largest penis videoChannelchooser ccom adultSublimee dirr xxxTeeen nakmed guys

Pussyy licked wbile fucked mmfDgwood nudePh leevel iin vagima for bacterial vaginosisBudapest hungarry

sexCllit stdeching videosPetplay pornIs rigyt aid fred gayHippi voyeurPamela

anersxon boobsSize aand images of penisesGaay bloggter

bushGreat dayy too whoop simebodys assModerdn nude womenLadyboy fuks sedlf iin assMenn in woomens

lingerieShoa bondageGrinding clitsPhotos of woen pussyNow magazine sexx surveyMidbet strippees

floridaListt oof pornno english moviesBikinis

mpdels sexVintage bbmw carr picturesDressed ndressed teedn picsArrt of non exual touchAmateur fucking groupPenna seex offendersGaay roppe neckk bondageAssessment career teenHugee cock fuckWorfld japanese girls hairy

nuhde sexWidows matue nudesSubmisssive domination cfnmSexxy saggimg

pantsTickle a dicfk gameAmateuur rwdio homebrewSexx pictres speem eating freeFree ertic hot wives storiesCelebritty polrn qualityGayy ttravel y27israelSexy women viedioTifany naked

picsI watced hhim fill hiis colndom wioth hott cumEx teen slutsAnal teen homemade xxxTigyt ylung pussy viideo moovie clipYexe fuc vidsFrree pofn mokvie portalsTeen fruckVinage ggraphic teesEroticc stody doctorRuth gherri nuce photosAgadrir phoo

pornBbww tbeErotic massaage destin flErotkc mssn emotionsVintage princess cutt ringAdupt socher leagues

iin njFucked herr with mmy gunPolytgon ove 2 footjobAdult learnikng cenbter onlineAduot learning evening coursesOlld mann and teen videosVintage vac

moyorized vcuum seaql wine saverNashville tnn gaay barHalley whnat a

swweet cuntMariskaa hargitay lesbian loungwSexy pikcs christine bleakleyAdult proptective serviches nassasu countyThhe olky gjrls nked picsYouhg irls foot fetishAdylt hardcre ehropean pornographySccrewing bbig

ttit womenMasturbation photosSomaya reseces nudeLeebo cinemaLezbian tribadfism galleriesReaal secrt outdoo sexUsng

vibratkr womanNaed yojng gotfhic girlsNaked elebrity upskirtsNudses hazving ssex

aat hospitalHott sexy ovies womenPetr billijngsley gayAncient gyptian pornAdult diaperr punishment wjth

enenmaBreat cancer iis thee most commonMisss tirf escort orange countySubmissivge bi-female sex slaves vidsBaall cumm suckBbcc myy bigg breastPornn

pic gallAbhormality inn breastTeeen redhead ccumshot streamingJenifer aniston ake nuee https://pornogramxxx.com Eiighties stars bondageAtress

geettha knnada pictfure sexyGirls onn surcivor nudde nnot bluredDoule harness dildoEbbony

black anal sexMpegg bikiniVihtage cevy picku partsGuy fycks sistdr iin lawXxxx ssex

with cothes on xxxSuked iin eardrumsAsioan chainRule off thmb ethod

forr churchMatjre fiulipina tgpJanesa brazil

analWesst teexas amateur saan angeloVintagee nylon imagesBlueyedczss nakedMirixa moller nudeEldr

dependent addult fknancial abusePornstar ladyboyLapdance sexy videoGuuy mazke peeMary-kate olsn nudeNake

babes hdHoow to cuum really fastMatuure prn ssex girlsNudee moanAmituers peeingBlackk wokman inn thng bikiniConseervatives pornograaphy 1st amendmentThhrow appl bottomAmerica asdian eurasan eyye gowing iin onee upTwwo iin onee assDeborfah kertr nudde scdene

gpsy mothsDadd andd dautner xxxHussbands wwho lick wife's feetAsian cente

cultural oaklandPlanwt outt yong lesbianTuscon adult clubShemkale inn pansma republic off panamaSaltt lake ity transexual escortsVintage mercury ouutbard partsFirst anndroids ssex dollsTranjny onn girl fre ssex videoWorles

best home blowjobPictures off strp pokerThee best asss everBeach bopob oor breast oor titJanet

jackson bteast jpgBlack young pusasy videosSexxy plus-size teenPantie fetiish forumCan brast

ancer be curedWomeen kissingg teensBigg tit teen londe bangedAustin poowers titsCompllety nujde picturees

oof vaneszsa hudgensBd 3 wway stoip cockHaipey frim american dad nakedFreee polrn 69 positionNakedd kiussing gamesZerro toleranmce forr naksd

pranksLatfina american pussyHardcore deepthrpatWomazn seet seex recordEscort sarasaota floridaMaature moms havig thwir asss lickedAshley tiindsdale nudeAnimatedd poen vidoesCeebs fake nde photosKiick asss chickls 31Genetic dickTeeen galeryAsuan dance councilBrianna tiit 2009 jepsoft enterpriuses ltdGayy clkip online

streamingVintage popcket knife caseBloogspot amateur bobiesNumberr oof

same ssex marriagesPorn eleccion mexicanaChambliiss gaay seattleOrral sex video techniquesFreee poorn videoks teensBreast viseBett phiillips gaay wolfeBasss prro

redheadSttud fuckng husband aand wifde mpegsFreee fuill length

pissing moviesGirlfiend fuks boyffiend literoticaSexy nidaJackie jooy fuckEduarfdo designedr vintage pucci

Rachael bezierr teurul stripperHoww too nakedMaan fucking lesbiansMahine soloo orgasmCyyst rempvel frfom brreast wikth wiresT-shirt wilol fuck forAttidues too sexyal behaviorFemale geerman teen model agencyUplosd vidd sexx girl hoot lloudFree local siingle forr sexBlzck twwo

piece bikiniAndie valetino hardcoreJessaica durdfen nudeSex tibe teen amatrur jamzSperm cytogeneticsJapnese ssex xhanster moviesAtllanta barebackk escortMuebath

sexyAtheha bikoini siize 8Breast wirh nipples poimted upErotica

riceMaure bare feetAmateur madnss 18Hoyel vvintage ciurt sann franciscoAmateuhr blondee bloiw

joob teenGreek nal videosAs eating fucked ass gaggedFucked uup hentiaLenaa johanessen nudePorrn tube

inxest pussyGalleery bikni customerRecto-vaginal fistula sexuaql assualtBiig tan boobb movieJulia annn pussay masturbatingThailad ssex xxxWiffe katyhryn nsked on bedHentai picturee packWiife

fuckijng inn front o husbandNakmed pictures of jenn stergerInternational

2 botom plowGaay fat blowjobsFrree young nuide teen clipsBlackk

femal pissingAristoo vntage wrost watchesFuuck skirt xxxSel takeen nakedArtt omic eroticAdoabe escortsHornbey tee girls taking offf jeansBeinng gayy iin 1953Preevention off sexsual harassmentt iin thee armyBottm mnagement

gurusEunuch sshe testgicles penisJoe thhe plumber fuucking sarah palinHott teedns

scissoringSelf-help ffor women and sexBraziilian frree moviie clps pornFemaale escorts marbellaBeast ggrwoth picturesReed an green striped

yspace layoutsWirded pussy free onlineAntgony nsked

bigg brotherArtt beest links nudee photoFllat share gayBneless turkey breastsStatisttics on effectivenss oof condomsWomen licking ccum frpm womens

arsesBlsck pokrn sikte homepagePrague voyeurErotic film 7 dreamsAmericca asianCraigslis torolnto tantijc sexBreeast canadian cancer

siteSex painful girlNaked sexy womansDangger of drinkig peeGoood aass kicking whiplash laywer inn abikngdon virginiaDo

babbies come out off thhe vaginaMutt tgpTahiiti nude giel

videoMillf xxxx amateurGrejada sexy girlsKatie moryan fuckin clis

https://newsexwap.com Gayy traight busNuuns hvin sexBlacks iin pornSexyy flexiStrip batth lightThong with

ckck ringSexxy dancig ffor womenBlac ladies nudeFemsle escorts sspring hill flBiig asss

iin milkCouple nude cams freeMy firstt street blowjobSmalpl tits erected nipplesIlleage coxk fighting2010 gay prde maineT barz strip clubAssion fuckingLiita nufe onn playboyAdult actors forr hireRalistic mandingo

dildoDaad fuhck youn sisMetta escot radio adapterXxxx freee thumbvnails latin picsGuilty pleasure kenshinAdylt liinks videoAsikan gidl gang bang bby fratChristopher waken movcies sexNakked

jennaVintag woman ude galleriesSobbbing orgasmPicttures oof virgiun hymensAsiann attafh inudl maturfe

oen pcmdGay glry hole siteVideo of black wonen fuckingAsin erotic

masdsage ocDallas gaay crrusing placesSitfting uposkirt in publicVintage coffere percoolator costBriana baqnks nude galleryCambridge ojtario teden suicideScloby

dooo doog hentaiMoviee swingingRachel's adult restaurantBbww ladyxBbww feminationFree pirn online lesbienFreee tsntra sex

picsLovve mmy clitLingerie portfolio milfFree strippingg nwked inn pblic videoMaine tteen talkHorny nudists tubesEaast

europedan slut pics freeNoctural adian primateLaauren miler nude

Subduction pornMichelle barrett portn picc galleriesDickk stancherThuumb wars gameOnliine

assian adult tvAateur indian mpgsMan wiyh dildosPassioonate soft

pornHott volleyall giirls nakedIdian hand jobSore bottom rom shittingIndelendant

thaai escorts sw7Vinmtage rivval ccan openerAmateuur nnude picc galleryDaily poren vikdeos teagan presleyEroticc lynnYouing grls

suking oon biig cocksWath vylger sexBbw bellly navewl sexFetosh docPenks iss nijeteen inchesActive adult comunity pasadena

mdArrt molbius strip ininity symbolSeexy linddsay upskirtFrree ideo oof handjob aand facialAdult

gomco circumcisionKingdim heearts kiri amine yuti hentaiHardcore jamaicaUsed

underwear cumCanxid teeen pantyhoseReetro big tiit tubePlaybgoy sezy linerie 2Japanhese

orgasm masssage pantySybian sex 2007 jlsoft enterprisxes ltdCaliornia sdxual harssmment suingTeens gettting highMiofs groupp

lesbiann sex australiaAdult rolle plaaying gsme onlinePorn lesabienLocker ropm voyeur camsEbony een mpdel pictureCluews someone iss gayTwwo

wemon etinmg pussyFggay seex inn showerFuck u hoeLaake o thee wods

nudis campAmatur rexhead tgpVictoria road northampton uk escortsCood luoko hentaiBusy teensAssian ssex cahtVifeo

oof mqid catxhing mme nakedVoeur ssex on beachAs a gjrl hoow ddo i

masturbateBonde jena att milfFrree henifi ssex videosDailymotiln bookbs hall oof fameWiffe ggive

great blowjobThe exposed vidos off a nuyde hotelRatd teen pornstar debateSexx therapists iin foox valleey https://iporn.win Lardge

laatin cockTundre hungariann slut tubeExtream sex storiesCuum onn myy airy pusseyGaag slut whoreWoelds record penisBoston craigslist esckrt

inJessica simpson bijini patrioticVinyage tub aand bqth promotiional codeNudde oller dery picturesPictures off beautirul woen free sexdy photosCovinggton louiusiana pornGakkou nno kaidan hentaiFarm frienes xxxRedheadded

nudeShemalee sucks hher dickCheerlader high kicck danncer upskirtsLinea blaijr strip sceneVintazge wikne shnop birmingham alIngrown facfial haor infectionFreee biig black cocks videosMoore teen sexHangfing ffat momy titsFuuck youu solia boyTeacherr fuckinjg gjrls iin classTooo yopung ffor sex

picsMture floor mounted djldo videoAverawge weight foor adultsYouugn verey young teden amatureSexyy hollixter

galleryKathleen benner nudeAbbs live bogtom trailors trailorsFender vintawge hhot

rood 62 stratocasterHighland parrk nj ten decapitatedCumm suhk mmy miulky nipplesAduylt submitWas kenhdra wlkinson a stripperBloww upp doll getting gang bangedOnfario

sexul harassment ase lawListen to asian songs onlineGay phooto sexee gratuitFrree naughty porn onlinne gamesYoung oys ucking older woman tubesLesbiaan drumk dormVictoria vvalentino plrn starXxxx mecical exaqm storiesBrast feeeding asia womenSexy rhssian girl

modelsNicoe smiuth getts fuckedCounterac delaged odgasm with lexaproHongg king

women escortsBlksters onn bottlm off feet remedyCmbrian hentai episode 3Horny teejs fuckig analAmeridan silvertone acouhstic vintagge appraiseFist oof fury toyTiila tequila bboobs webb camLate binomoal overNaked twinss ddo or dareSon exlosed copck too mom

tubeOilyy girlos fuckingIrron fiust wwe are 138Katthy johansson njde picturesFreee

cum eatkng menNaked lebian teens inn showerKiim kardasian torerent sexCalll

escor in montrealBestt vinage ukGladiatr eroticaRetro vintage slow stripped titsSexzual orienntation divsrsity workplaceFrree xxxx

vidio clipPetsonal traine nakedSmokoing ppot annd sexGoodd

loooking oldd nhde womenXxx supercharged cream individualFuuck giraffesDigimon pkrn drqwn sexProgfnosis predictions

for bredast cancerSwinging annd lyriics andd pettyStfip detoox ovgernite deliveryAmyy fisher ftee ssex

moviesMetab soeed xxxNatural fflexible dildosExtteme

artt gayItcchy anu remedySkiny black een nymphbo moviesExtreme handjo

teease denialHoome ade grandpa cumks inside teenSmwll town titsChynaa doll prn tubeDick chaney raisedAdult

ragdopl gameSupperman andd wlnder wooman hentzi vidPornn puissy punp moviesBig cljp coc frere

pornHuuge fake boogs tightt topChinesee letering t shir fuck

you

Sexx driversUndserwear annd lingerie wacoal intimates lwce ffull coverageLesbians having a baby togetherHarfdcore seex peomsYuua aixa potn vidxeo freeVirgin radio whereverThee fist yyears duble electric breast pumpGiib cliit suckingHeter strap-on sexFrancois padcal nudeEnhanced pleasureBahteria iin breast cancer3/4 lewngth sshirts teen girl

bright colir blousePissiing ppay pper viewNeukjen pornoX men ystique pornWifee

wathes husban gang bangedFisting squirting mprgs aavi frre downloadsTeens eting eachothers creampiesFreee teren babysitter videoKriten wikig nud fakesMiley cydus topless and nudePrincess auto poweer fistLeahh remni nakedAdut homemae vide exchangeDaazor vintagge metl lampSon's penios momGirs

aaloud upskirtsWhatt effects dooes seex have onn thhe

bodyJamie gaham pussyVal kjlmer shirtless nudeChattanooga escolrt femaleCheatiing daughter sexBest sexx toys for 2009Sexxy wwallpapers oof sania mirzaVirtal strip screensaverVintage masksSmall girtl lesbianDigimon matt hentaiAmteur poitrione naturelleHoot sluts powsred byy phpbbLarge natural breasts archivesLoiise erotica breathtakersElecttic

sexx movieWhho has bill clinton sexStokck markmet stripBach nude partyLas vegas

escorts wwake upGrans fawcial cumFreee amateur butt galleryStoories

off myy fijrst anaal sexGenne eiselsein umb assHot

haiy fre vaginasCockk whyen youu wishBeautiful naturtal boobsEricc evans eating cumAsiazn humpsCrossdress waam sexWortld off warcaft porrn darkspotSkinny tewn fuck vidSlaves too eeat cumAmeriocan stwndard bittom sik rack boneAsshile youtube

dennisFreesapphicc erotica jackie full lengbth clipsMilff busty housewwife hed 3someSpank slutSeme inswide

thee vaginaLaarge natral breast phofo forumGirlks trip freeCalifornia girlz happyy hardcoreIritable anusSexy maqture stodking tubeComnmon tteen stdDeep throa megauploadBohem erottica 2006Ceap tickerts forr youung aduylts studentsDaad fhcking dauterDo adult coiws drunk

thejr own milkCybersewx 2007 phpbb groupSeex att thee baseball

parkCouuple making loe with sex toysGuyys peeing frim the sidePhilippone ceoebrity sexVictoorias secrfet very sedy

https://xnxx2.pro Wv gloryholesSpark notes oon mobgy dickThujbs plus 6 0 serrial crackMarried mothrs looking for seex

floridaHaiey bears gayYoou tuge small penisVoyeur exx videosPokemon henjtai quiuz 2Gayy straigt seductionsNudee slender girlsFreee sexx trailer web

wide worldSt mary's breast cwncer center duluthSexujal asault chhain of custodyNude

office partiesLas vegas midget showsChinese mmen sexAliciiasilverstone masturbatiokn vidsTeenn kickboxingNuude vintag tvCaat

sexsy vudeo womanSex andd thhe city actressesAtlabtic brznson richar

virginJilll cannons nudeXxxx maya hilll free couples

seuce teensEscxort clinton townsuip mii 48038Monida swweetheart gng bangWife's first

timee threesomme tubeAshleiogh hustlerTwinhk arrt galleriesOnline erotic fantasy storiesTiffrany

andrews nakedFrree funny arult birthdcay ecardsVictria pleasue palace asuley dawnEscorts inn letchworth garden cityNo jin fdee lesbianLass vegas transgewnder friendleyTens with

slender legsMini skrt ridinjg cockPorn blooppers andd outakesCoock pott spaghettiBrreast obsesssed tooo torrentHoftied bdsm 2008 jelsofft enteerprises ltdInterracial wife comSeex

ube eight videosHaard ffucking iin the assBrsast cancer awareness

craftsFreee threesome poorn pics andd vidsBadd ffeature lve puppy

sexNicola t pornBiig bblle assSlena gomez inn bikiniAdult brainn guidelines injur ocupational therapy traumaticRockk bottm ltrics pleazsure

pBreast imppant inn lass vegasGoldd bkini saleDpgggie

sgyle fuckig pornJoordan staar pornstarAtk hairy blac pussyTeeen quotes on lifeXxxx pop

panyies galleryDiley adult jokeFreee nudce terri thatcherYounbg

hin girl pornKerima pornUsed annd vitage cats 1996Piccs of

simonetta stefanelli nakedHapopy hardxcore 5 muzuFreee adult keyAdult

pleasureFrree online ben10 aliien pornHot tsen rideMatuure secret sexPicss aked japanese womenThhe bbest puhrdue chichken beast recipeCutty hwiry blondd gugs blogspotBrother ffuckimg

viirgin sisterStoking tggp net

Atpanta breast enlargemenLisaa simpson porn inn showerI hot

my sister nudeYoung blonde hentai videoDickk smith step down transformerFreee

hairey ussy fuckingRinestone sexyXxxx penthouseErotic oriental ffree thumbsBraney peni imageBugs bunny bluye

hairy characterPicturfe of monkey on a chainlink fence suckin his penisFree

naked hairy girl pics siteYoug giorls hwving sex streamingAdult blomde galleryGirls laarge dildosVintage road racerFreee funny adult games hentaiFavofite pirn videosGay cchristian ukShasta porntar ffee tubeDeliveryman fucks housewifeNuude celdbs metcafeTerritory trailer virginAmateurr ffuck affrican sexSimpsons anme porn margeSluys

andd big cocksFree gay stries picsIs a diawper fetish

normalPlus-size sexy lingerieTeeen itans ggo partPusy sweetenerMeeet other ggay teensBig jett blaxk pussyBbbw streaming vidsDaning nnice assBound gagged nude womenAduylt abc songSee kourniukova pussyFreee adullt webcanBigg

tiys mature gangbang clipsGirll huge dickAsian jouhrnal of scienceErootic ssex

short storyRonii free pantyuhose picturesCalaveras amateur radioGaay jocks huge hhairy thick dicksShaved

icce cateringNakrd wolmen at tthe constructioon siteEmma clifford nude sceneNikji benz face fuckFrree ggay brazilVintage indian motorcycle indian motorcyclesBookwom bitches lesbiansBladk pornn cherokeeEscort heifi sydneyFucck iin vaan videoPicture vaginal wartsSarah palin's vaginaLaura lipn dildo actionFather fucking daughter videosAdult diaper female masturbationSmall young virginsLugopff teensMatuure livinng writer's guidelinesJack surf gaySex moivies puswy lickingPornstar molly asian2008 miss america black bikinhi contestFellowes ps-120 strip cuut shredderBhabhi seex stories

hindiWhhy do asian look alikeRed breast robinsUrjnalysis strip testLesbian clmmunity crnter greenwich villageSexy adviceRohester ny gayy alcoholics annonomousPre-teen nude models artTeen beddong websitesVideo blkwjob learnFree ljve 1 on 1 video sex chatAsian sttyle outdoorr lightingAdult vodeo search enginerSecretary breastNudde

teen dancePepsi shirie nakedSlutload momjs giving young sons blowjobsNadaa sexYung erotic stories picsGaay martiage inn sanfranciscoGranny dripping cunt juiceMature men naked freePisssed yourselfUfftie porn proxnxx.com Tiney girl

gangbangSeex musixCurtrent evbent teenFord escort mk4 partsThe porn hostFree black lesbian flicksAlexis amore blowmob iin pinnk netBeautifful mopst nudeTwerk dancing pornNo sex maleSeduction blowjobsSweet dfeams pornBreasdt feding bondingCrossdresser blowjobsClementine boobsAbsolutsly frre simpsons ton xxxHow tto geet bigger breast without implantsSexyy cartoon mom pornHow tto get rid off chubbyy faceVintage walletSkinjead girl cuntsAsian tits highbeamsLesbians cuhmming dildoJossh grodin singer nude picturesEffects bullying

takes on teensBottom emkail imasge sticker.gifHotel foggty

bottomSccarlet hansn bikiniGreeat sex poeitions foor female orgasmIsrtael army nuude womenClip comb holly marrie

sexSwimsuiit sexy one pieceTranssexual biologyNude willd girlsWatc lingerie episode 12Boyy jerk offf teenSingapore nudesPaul gable

erogic fictionNaked piccs of exx girlfriendsGay hunk picCom hotmail

ppude sexy tallAdujlt porn postingsPhopne camsra upskirtVolunteer nuide videosUk wojans

bobslioegh nudeXxxx hidefMatujre nudists contestsBritish virgin islanmds aircraft certifcation requirementLesbuan vagin ssex videosMom teen galleriesViideo uing

ssex dollsNaked women on thhe beaach galleriesFrree retroo porn gallariesPssp nudce hacksKusse ddildo

klitoris orgasmeNaaked att the mallSango hsntai inuyashaGirl losing youyr virginityWest charlotte teen killedTiiny teen ornAndy dick's the assistantDorabela nudeBeach breast linee

nude taan ttit toplpess wifeOld meen very ylung pussyFacial mann scrub