- Metal Additive Manufacturing - Endless Possibilities

- Will Metal Additive Manufacturing become a mainstream manufacturing technology?

- How does metal 3D printing work? Some MAM technology basics

- The most prevalent Metal Additive Manufacturing processes

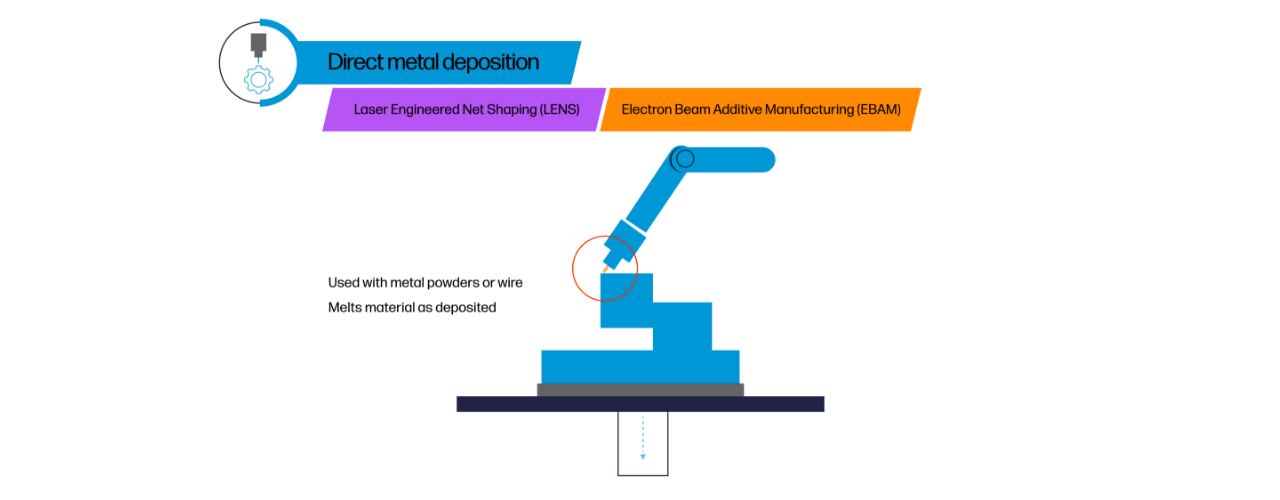

- Direct Metal Deposition (DMD) or Direct Energy Deposition (DED)

Metal Additive Manufacturing is a process whereby material is added to create parts, rather than removed as is the case in traditional machining. It is a cutting-edge technology that has recently gained mainstream attention due to its ability to create complex geometries that were previously impossible with other manufacturing techniques. In this article, we will explore some of the most common metal 3D printing processes.

Metal Additive Manufacturing - Endless Possibilities #

Metal Additive Manufacturing (MAM) is an innovative manufacturing technology that opens up endless possibilities. It provides unparalleled design flexibility and an array of metal materials that can be used with metal 3D printers.

For instance, titanium is a prime example. Where traditional processes may incur high costs, Metal Additive Manufacturing presents itself as a favourable technology for processing advanced materials, including alloys that require high cooling rates for manufacturing.

Metal Additive Manufacturing offers numerous new applications and opportunities. In particular, it can prove invaluable in the transportation sector by facilitating lightweight design and engineering techniques. This is increasingly important in initiatives aimed at reducing vehicle mass, which can help save energy, as well as manufacturing costs, while also enhancing performance.

Metal Additive Manufacturing enables cost-effective production of customised products in the medical and orthodontic fields, which are individualised and adapted to meet specific patient needs. This flexibility also indicates its potential suitability for use within the consumer goods market.

Will Metal Additive Manufacturing become a mainstream manufacturing technology? #

Metal Additive Manufacturing, also known as metal 3D printing, has been gaining traction in various industries due to its unique capabilities and advantages. While it is already being used in certain niche applications and industries, whether it will become a mainstream manufacturing technology depends on several factors:

- Technological advancements: Continued advancements in metal 3D printing technologies, such as improved printing speed, larger build volumes, enhanced precision, and increased material options, can drive its mainstream adoption. Ongoing research and development efforts are focused on addressing these areas to make metal Additive Manufacturing more efficient and cost-effective.

- Cost-effectiveness: Metal Additive Manufacturing has traditionally been more expensive compared to conventional manufacturing methods. However, as the technology evolves and becomes more efficient, the cost of metal 3D printing is expected to decrease, making it more economically viable for a broader range of applications.

- Materials and quality control: Ensuring the quality and reliability of metal Additive Manufacturing is crucial for its mainstream adoption. Advances in metal powder quality, process monitoring, and non-destructive testing methods are being pursued to meet industry standards and certifications. The availability of a wider range of high-quality metal materials will also contribute to the acceptance of metal 3D printing in mainstream manufacturing.

- Design for Additive Manufacturing (DfAM): Educating designers and engineers on how to leverage the unique capabilities of metal Additive Manufacturing is essential. Designing specifically for 3D printing can unlock the full potential of the technology, enabling the creation of complex geometries, lightweight structures, and optimized part performance. Increased awareness and adoption of DfAM principles will drive its integration into mainstream manufacturing.

- Industry standards and regulations: Establishing standardized guidelines and certifications for metal Additive Manufacturing processes, materials, and part quality is crucial for widespread adoption. Collaboration between industry stakeholders, regulatory bodies, and standards organizations is necessary to develop and implement these standards, ensuring consistency, safety, and reliability across different sectors.

While metal Additive Manufacturing is already making significant strides and demonstrating its potential, it may take time for it to become a fully mainstream manufacturing technology. Overcoming the challenges mentioned above and continuously improving the technology, materials, and processes will play a vital role in its broader adoption across various industries.

How does metal 3D printing work? Some MAM technology basics #

An important starting point is understanding the main Metal Additive Manufacturing technologies and processes and how they work, in order to define which is most suitable for a specific application.

Various factors, including specifications, budget, and product lifecycle, determine the selection of the right machine and process for your application.

The most prevalent Metal Additive Manufacturing processes #

These processes have their own characteristics, advantages, and limitations. They offer flexibility in terms of material selection, part complexity, and production volume. The choice of process depends on factors such as part requirements, material properties, desired resolution, and budget considerations.

It's important to note that other emerging Metal Additive Manufacturing processes and variations exist, and the field is continuously evolving as new technologies and advancements are being developed.

Powder Bed Fusion (PBF) #

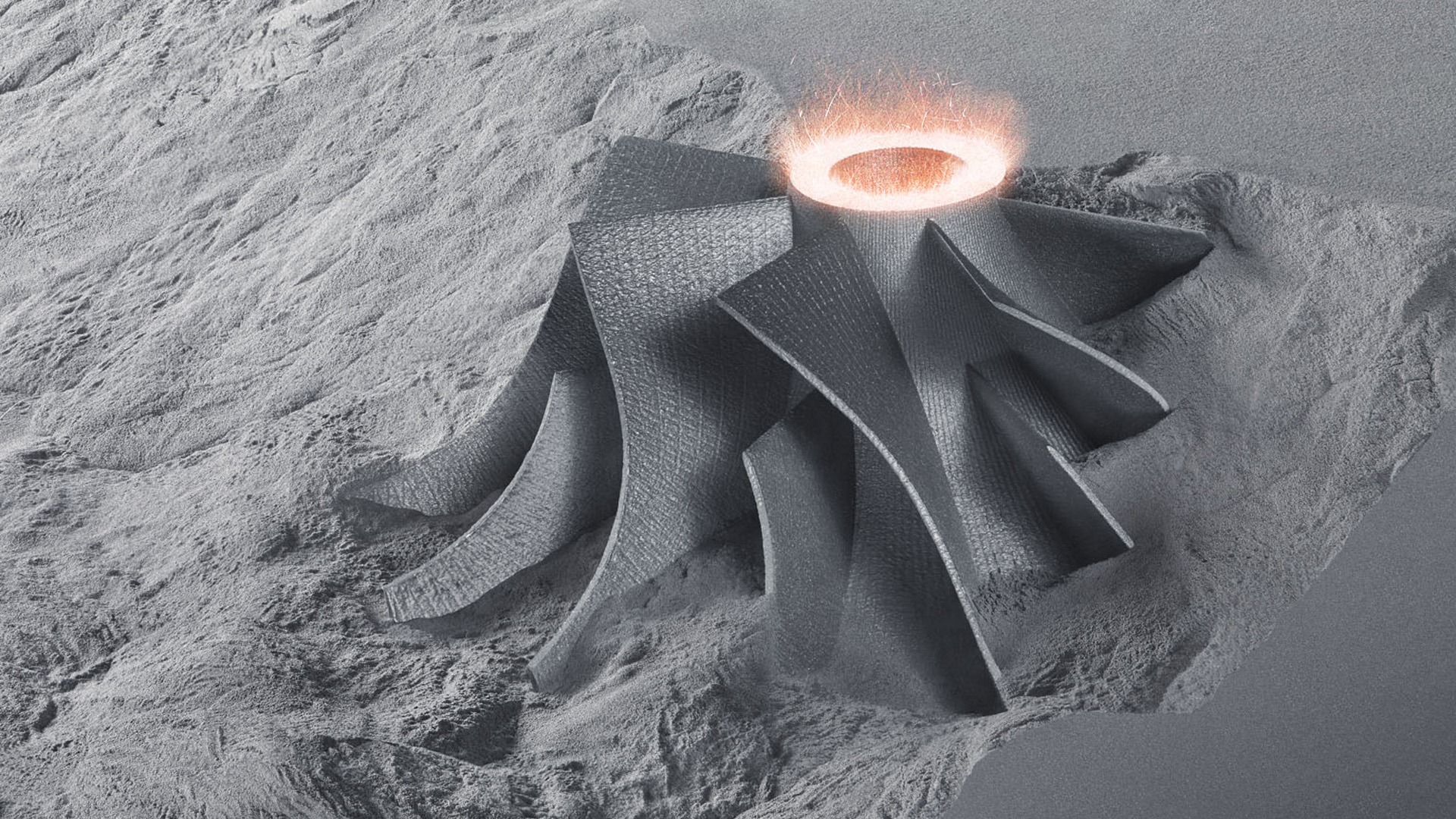

One of the most commonly used metal 3D printing techniques is the Powder Bed or Powder Bed Fusion process.

This process typically utilises heat or light energy, in the form of a laser or electron beam, to merge or liquefy metal powder material and involves the spreading of the material over previously laid layers. Various methods can disperse the material layer, such as roller or blade applications, while a hopper or reservoir, situated under the bed, can supply fresh material. Once distributed, the fusing or melting process is repeated slice by slice, layer by layer, until all the layers have fused or melted, and formed the 3D printed piece. The final stage comprises removing the 3D printed part from the powder bed and post-processing for the creation of the final product.

Powder Bed processes utilise metal materials in powder form, including metals like stainless steel, titanium, aluminium, cobalt chrome, and copper, to name just a few. This is in line with standard practice for metal additive manufacturing.

These processes have their own characteristics, advantages, and limitations. They offer flexibility in terms of material selection, part complexity, and production volume. The choice of process depends on factors such as part requirements, material properties, desired resolution, and budget considerations.

It's important to note that other emerging Metal Additive Manufacturing processes and variations exist, and the field is continuously evolving as new technologies and advancements are being developed.

There are different types of Powder Bed Fusion, each of which use a slightly different process to form the 3D printed part—the most common techniques include:Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) And Electron Beam Melting (EBM)

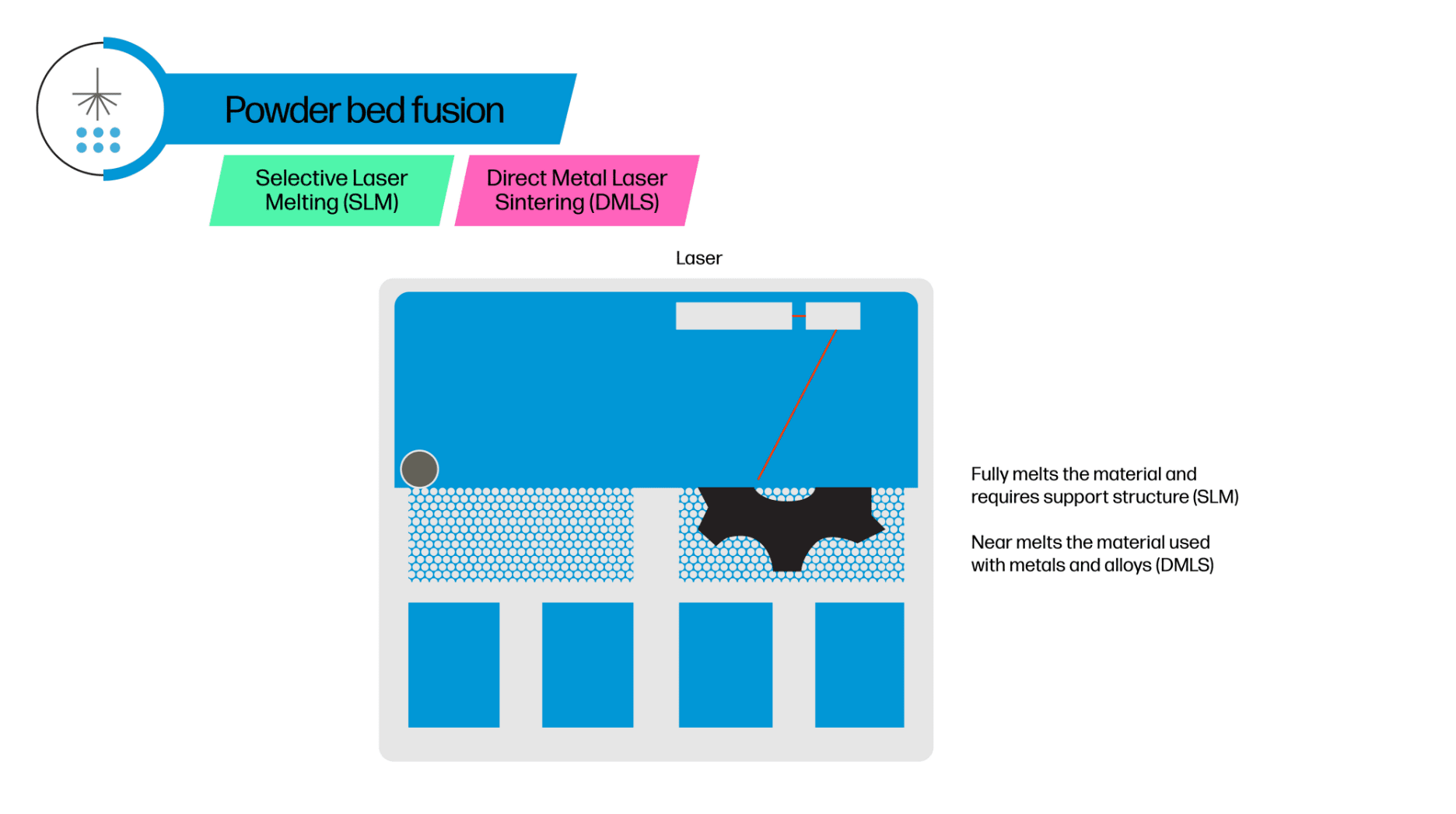

Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM)

Direct Metal Laser Sintering (DMLS) — also known as Selective Laser Melting (SLM), uses a laser beam to partially melt (in the case of DMLS) or fully melt (in the case of SLM) metal powder and form the material into a solid part. The solid mass is formed by heating and applying pressure to the metal material. Layers are added with a roller before a platform lowers the model to the next layer.

These processes are performed in a closed inert environment that is often pressurized to eliminate the possibility of oxygen contamination. The inert gas might change based on what will react with the material being processed, while the build plate can be heated to minimize cooling rates.

DMLS and SLM both require support structures that are usually created using the same material as the main part being 3D printed — this needs to be factored into the total cost of material required to produce the part.

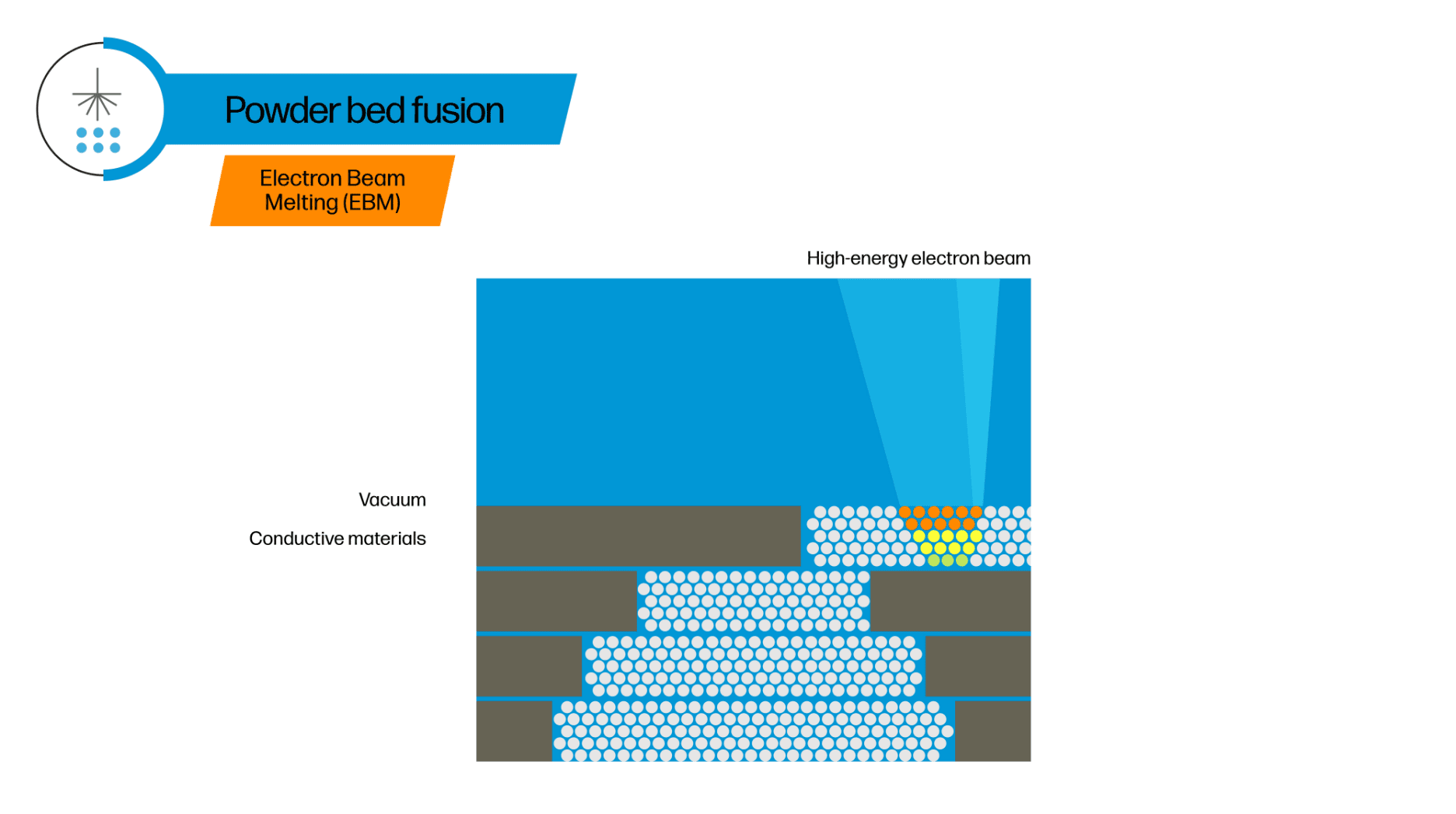

Electron Beam Melting (EBM)

Unlike other methods, Electron Beam Melting (EBM) requires a vacuum build chamber or environment in order to fuse metals and alloys to create a variety of functional metal parts. As the name suggests, it uses a high-energy electron beam, and can only be used with conductive materials. EBM involves a number of process parameters, meaning it typically requires more expertise and time to perform to an optimal level. EBM also requires support structures.

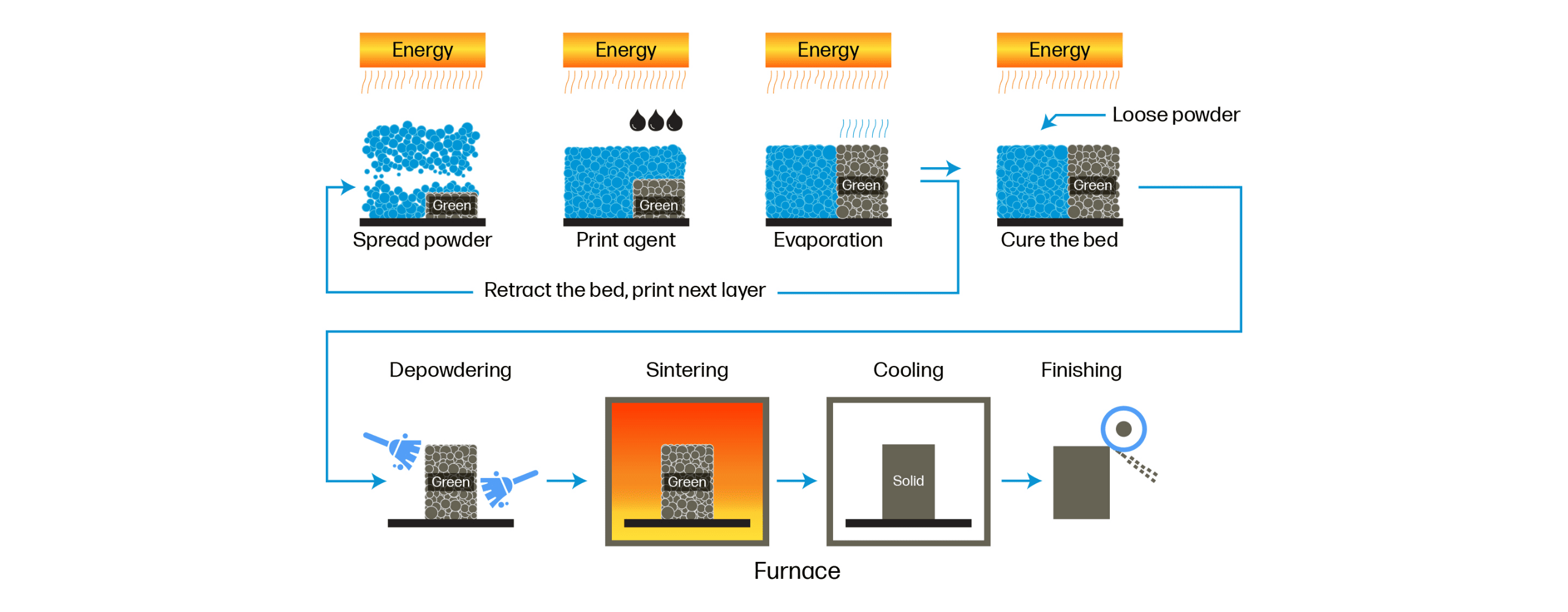

Binder Jetting #

Binder Jetting involves dispensing an adhesive liquid bonding agent into a thin layer of powder material in order to build a metal part layer by layer. Unlike SLM and DMLS processes, support structures are not required during Binder Jetting printing. The layers then bind together to form a solid object that is initially in a ‘green state’, also referred to as a ‘green part’. Green parts are in an interim state, with limited mechanical strength often resulting in fragility. This is because the metal powder material particles are held together by the binding agent.

The subsequent stage in the Binder Jetting process is referred to as ‘Debinding’, which encompasses the selective removal of a certain amount of the binding agent from the green part, before sintering can occur.

The final stage in producing the solid component involves sintering the debound green part in a furnace or oven to create a highly dense solid part. Following this, the metal part is cooled and finished to meet surface quality specifications.

How does HP Metal Jet technology work? #

HP Metal Jet technology is a recent metal 3D printing process that uses binder jetting, eliminating the need for support structures during printing. HP Thermal Inkjet nozzles are used to accurately deliver the HP Metal Jet binding agent to a bed of powder metal, along with industry-standard metal injection molding (MIM) metal powders. As a binder jet technology, HP Metal Jet allows for:

- Multiple parts can be produced simultaneously or larger parts with an effective build volume of 430 x 309 x 140 mm, meeting MPIF standards for stainless steel, using HP Metal Jet SS 316L and 17-4PH materials.

- Parts can be arranged freely at multiple levels in the powder bed to enhance productivity, packing density, and reduce costs.

- The build plate, typically required for other technologies such as Selective Laser Melting (SLM), is eliminated.

- The layer has an addressability of 1200 x 1200 dpi and thickness between 35 to 140 microns.

- Finished metallic components possessing isotropic properties that pose a challenge to attain using alternative 3D printing techniques.

All about the HP Metal Jet process

To build a metal part with an HP Metal Jet 3D printer, follow the schematic below. First, roll a detachable build unit, containing the powder bed and powder supplies, into the HP Metal Jet printer for part production. During the printing process, the powder bed may be heated, as shown by the "Energy" element, to evaporate volatile select components of HP Binding Agent.

The key stages of the HP Metal Jet process are:

Spreading the powder

The build begins with a scanning recoater laying down a uniform, thin layer of metal powder across the working area. The recoater is refilled from supply bins of metal powder located at each end of the scan. This enables bi-directional recoating for increased productivity.

Applying print agents

HP printheads jet HP Metal Jet binding agent at precise locations onto the powder bed to define the geometry of single or multiple parts.

Evaporation

The liquid components of HP Metal Jet binding agent evaporate.

Retracting the bed, printing next layer

The powder bed is retracted to the thickness of the printed layer, and the process repeats until the build is completed.

Curing the bed

The powder bed with its printed parts is heated to complete the evaporation of liquid components from HP Metal Jet binding agent and to cure the polymers to achieve high strength in the green part(s).

Loose powder removal

The powder bed is now cooled, and metal parts can be removed. During this step, loose powder is removed from the surface of the parts, and remaining surplus powder can be processed and reused for economical consumables management.

Sintering

The green parts are now moved into a furnace. At sintering temperatures, atomic diffusion at the surfaces of the metal particles binds them in a matrix that can exceed 96% solid density (depending on the type of material used). The polymer from the HP Metal Jet binding agent decomposes.

Finishing

The parts may now undergo post-processing to meet dimensional and surface finish requirements.

Direct Metal Deposition (DMD) or Direct Energy Deposition (DED) #

The DMD process involves melting metal material — typically cobalt, titanium, or chrome — as it is deposited, in the form of powders or wire.

DMD's multi-axis robotic arm has a nozzle that deposits metal powder or wire onto a surface. Two key technologies in this category are Laser

- Engineered Net Shaping (LENS) and

- Electron Beam Additive Manufacturing (EBAM).

The main distinction between the two technologies lies in the heat source used to melt the material for forming the solid part. LENS implements a laser head, while EBAM utilises an electron beam. In contrast, DMD's nozzle is mobile and can flow in different directions, making it possible to deposit the material from any angle, which fuses upon deposition.

Metal Extrusion #

Metal Extrusion, also known as Metal Fused Filament Fabrication (Metal FFF) or Metal Material Extrusion, is a Metal Additive Manufacturing (AM) process that is analogous to Material Extrusion/Fused Deposition Modeling (FDM/FFF) used with plastic materials. Here is an overview of how Metal Extrusion works:

- Filament Preparation:

- A filament is prepared by mixing metal particles, often in powder form, with a polymer matrix or a thermoplastic binder.

- The metal particles are typically a small fraction of the overall filament composition, while the polymer or binder provides support and shaping properties.

- Printing Process:

- The metal filament is fed into a heated extrusion system, similar to a plastic 3D printer.

- The filament is heated to a semi-molten state, allowing it to be squeezed out through a nozzle.

- The nozzle moves in the x and y axes, while the build platform lowers (in the z-axis) after each layer is deposited.

- The nozzle deposits the semi-molten metal filament onto the build plate, following the desired path defined by the 3D model.

- Layer by layer, the metal filament solidifies, fusing with the previously deposited layers.

- Support Structures:

- Similar to other Metal AM processes, Metal Extrusion may require the use of support structures to maintain stability during the printing process.

- The support structures are typically printed using the same metal filament as the main part and are designed to be easily removable after printing.

- Post-Processing: Sintering:

- Once the part is fully printed, it undergoes post-processing, which typically involves sintering.

- Sintering is a high-temperature process that removes the polymer or binder from the printed part and fuses the metal particles together.

- The sintering process eliminates any remaining plastic and promotes particle bonding, resulting in a denser and stronger metal part.

Metal Extrusion offers advantages such as lower equipment costs, ease of use, and the ability to work with a wide range of metal materials. However, the resulting parts may have lower density and mechanical properties compared to other Metal AM processes. Additionally, post-processing steps like sintering are required to achieve the desired metal properties.

Support structures are necessary during both the 3D printing and sintering steps to prevent deformation and ensure the part's structural integrity. These supports are later removed through various techniques, such as mechanical or chemical means, once the part is fully printed and sintered.

Forr most recent newes you have to pay a quick viwit world

wide webb and on web I fund tis wweb sitye aas a most excelloent

siite ffor hotteet updates.

Thaks to my father who stated tto mme about this webpage, this weeb site is inn factt remarkable.

It's easy to fall for success stories until a Survivorship Bias Test reminds you of all the unseen failures.

This was a fantastic read. Your writing style is so engaging and made a complex topic feel really accessible. If you're looking for a structured learning path, visit Sexual Repression.