CNC Milling Services

Source custom parts from our network of specialist CNC milling manufacturers. We can produce tailored CNC milling parts using over 50 categorised metals and plastics, with more than 15 surface finishes available. We are capable of tolerances as low as ±.0008 inches.

What exactly is CNC milling?

The process of CNC milling involves the use of rotating cutting tools that remove material from a workpiece to create finished parts and products. CNC milling is versatile in nature, and can be applied effectively to various materials, including metals, polymers, wood and glass. In general, CNC milling systems incorporate three linear degrees of freedom: X, Y, and Z axis. This feature enables precise and detailed output. Furthermore, V1 provides more sophisticated 5-degree systems that facilitate the rotation of the tool head and machining bed (A and B axis). 5-axis CNC machines can manufacture highly complex geometric parts without requiring multiple machine setups.

Maximum part size for 3- and 3+2-axis CNC milling operations

There are several types of CNC milling machines, each with a unique maximum part size. 3-axis and 3+2 axis machines have lower start-up costs and can manufacture relatively simple geometries.

3-axis milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm |

78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

|

[1] : Aluminum, copper & brass [2] : Stainless steel, tool steel, alloy steel & mild steel |

||

3+2 axis milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

|

[1] Aluminum, copper & brass [2] Stainless steel, tool steel, alloy steel & mild steel |

||

Maximum component size for CNC milling with 5 axes

Of the milling machine family, 5-axis centres are the most advanced and capable of producing components with intricate geometries These machines demand lower machine setup requirements, leading to increased productivity.

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

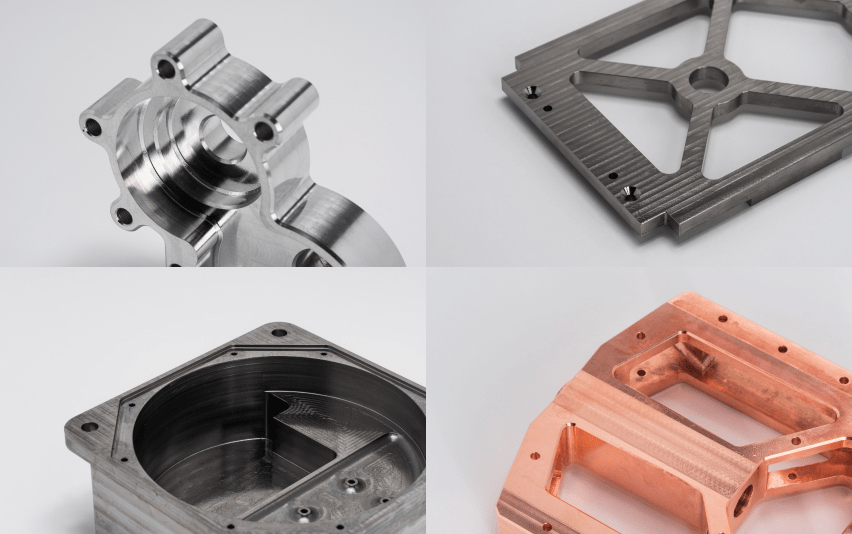

Available materials for CNC milling

Metal Materials

We offer an extensive variety of metal materials for CNC machining, suitable for various industries. These materials are perfect for creating one-of-a-kind prototypes and custom parts for end-use.

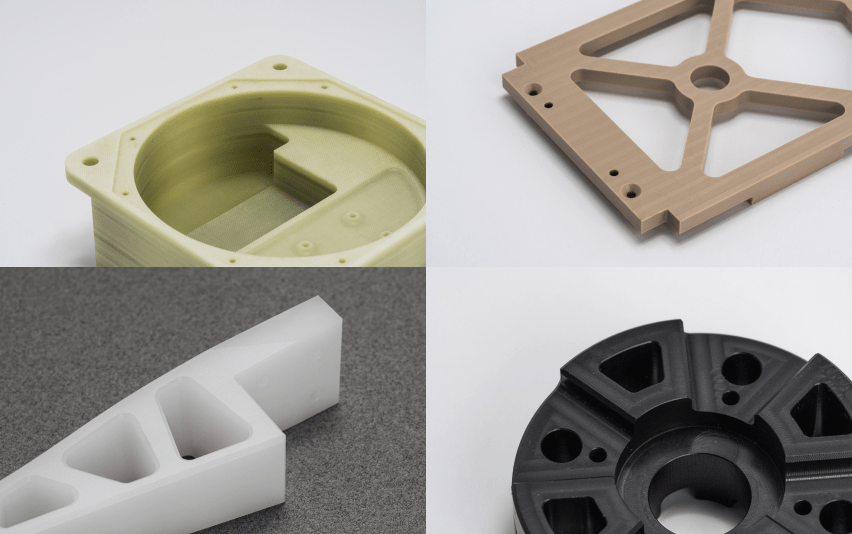

Plastic Materials

A broad range of plastic materials for CNC machining that are used in several industries. Suitable for creating both one-time prototypes and custom parts for final use.

Explore CNC milling plastic materials

Surface Finishes for CNC Milling

Improve your part's performance by selecting high-quality surface finishes that improve the roughness, hardness, chemical resistance and cosmetic features of your finished component.

Tolerances for CNC milling

Our CNC machining adheres to the ISO 2768 standards.

| Limits for nominal size | Plastics (ISO 2768-m) | Metals (ISO 2768-f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

Guidelines for CNC milling design

Verify the recommended and technically feasible values for the most common features found in CNC machined parts.

| Feature | Recommended size | Feasible size |

|---|---|---|

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) |

0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter |

Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter |

Size: M2 |

Our CNC milling operations adhere to high standards

The custom parts are manufactured according to strict manufacturing standards, and we ensure that all parts and processes conform to the V1 Standard. Our inspection report is thorough in its verification of these requirements and is shipped with every order.

- After machining, the parts can be left in their machined state or undergo a post-processing process for surface improvement or improved aesthetics, as specified in the PO by the customer's requirements.

- We perform in-house quality checks after manufacturing, but before sending the custom parts to our facilities or their final destinations. This ensures that every part follows the order's specifications and the V1 Standard.

We also complete any requested documentation at this stage, thereby ensuring that the conformity of the parts is assured, before the order is dispatched.