Online Rapid Prototyping Service

Rapid 3D printing, CNC machining, sheet metal, and injection molding. Parts ship in days.

- Parts in as fast as days

- 10,000+ manufacturing facilities

- 50+ materials

rapid prototyping

What is rapid prototyping?

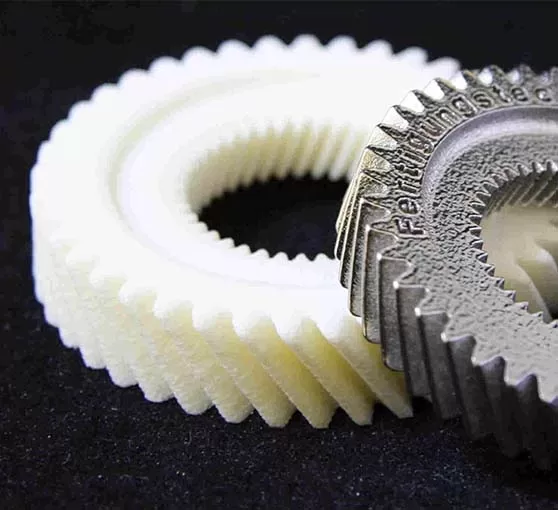

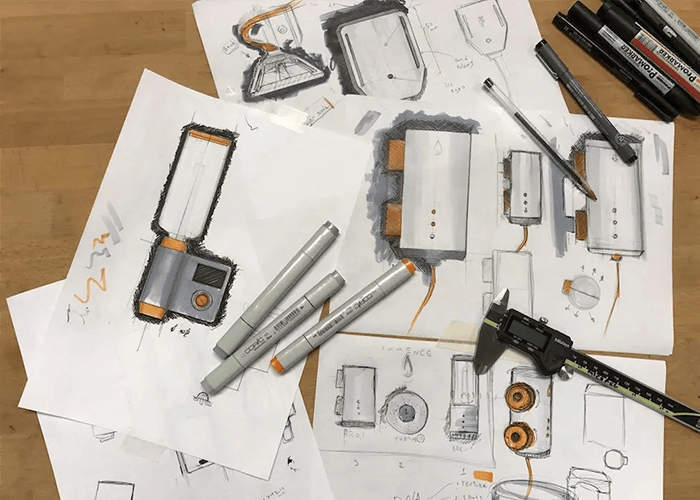

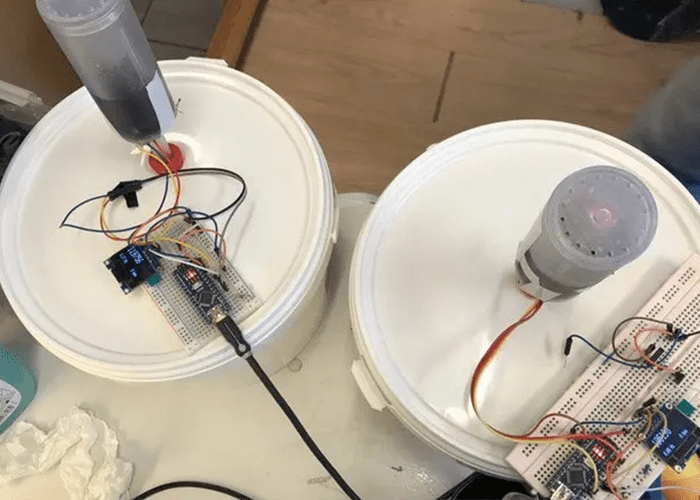

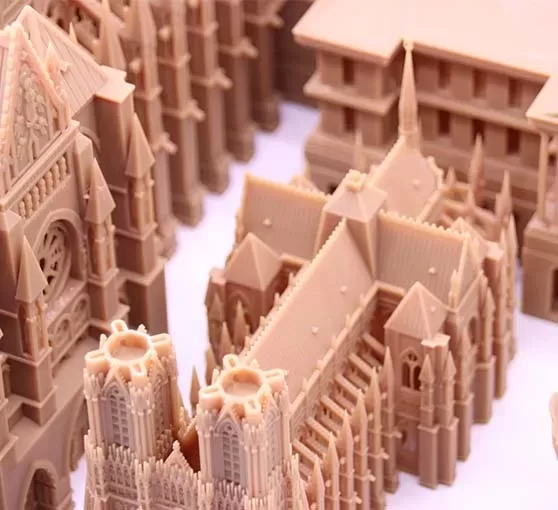

Rapid prototyping is a process that utilizes advanced manufacturing technologies to quickly create multiple versions of a part for testing and evaluation. It prioritizes speed and affordability, allowing for simultaneous production of multiple prototypes or quick modifications and remakes of a single prototype. Common methods include 3D printing, CNC machining, sheet metal fabrication, and rapid injection molding. By reducing financial and time risks, rapid prototyping enables engineers to test designs and materials with greater confidence, providing essential information before moving on to higher fidelity functional testing and production.

Rapid Prototyping

Selecting From Rapid Prototyping Processes

V1 offers a range of rapid manufacturing processes that can create prototypes quickly and cost-effectively. This service is ideal for engineers and product designers wishing to speed up product development cycles. While numerous methods can be used to produce any given prototype, the engineer is responsible for deciding which process and material are most suitable for their product. Recent advancements in additive manufacturing technology have made 3D printing the preferred choice for engineers who are looking for rapid prototyping solutions. This is because the parts can be printed quickly and affordably using various metals and plastics.

3D printing prototypes

Accelerate product development by 3D printing prototypes in-house

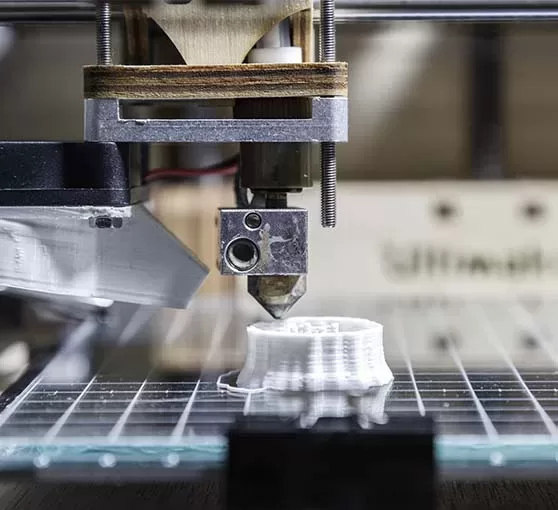

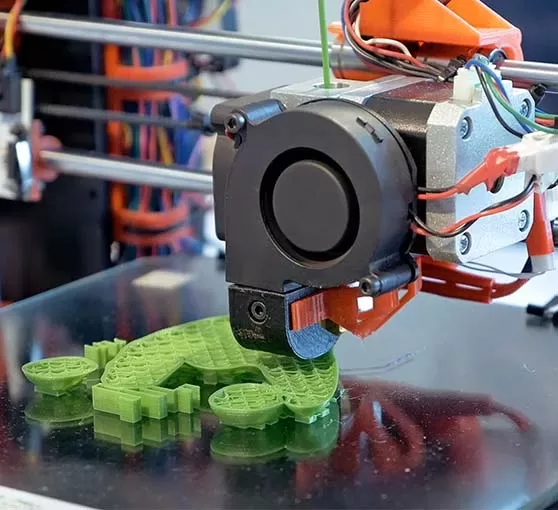

With in-house 3D printers, you can produce prototypes rapidly and easily iterate on design, size, shape or assembly based on results of real-life testing and analysis, thus enabling you to bring excellent products to market quicker. Turn your ideas into practical proof of concepts, then progress these concepts to high-fidelity prototypes that look and function like real products before guiding them through a sequence of validation stages, until they reach mass production.

Reduce the prototyping cycle to 24 hours

Avoid waiting for weeks for prototypes to arrive from a service provider. Through in-house 3D printing, you can quickly create prototypes within one day, test them, adapt your design and print again.

Our Rapid Prototyping Capabilities

Transform your ideas into stable models quickly and easily with our all-in-one rapid prototyping solution for proof of concept. Our team employs various rapid prototyping technologies to guarantee accurate models with exceptional surface finishes.

With fast 24-hour feedback and excellent prototype detail and mechanical performance standards, we can quickly iterate and gain crucial insights for design validation, market feedback, or pre-production.

Kickstart innovative ideas, validate and receive feedback, and jumpstart productization.

SLS

SLS rapid prototyping service

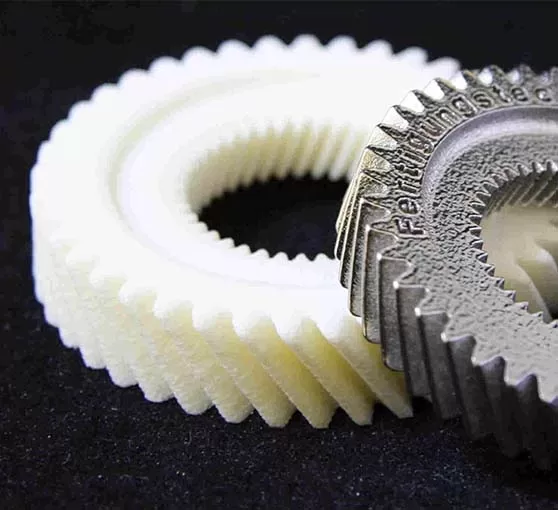

Selective Laser Sintering (SLS) is ideal for producing functional prototypes of plastic parts that require good mechanical properties.

| Standard capabilities | Description |

|---|---|

| Maximum build size | 300 x 300 x 300 mm (11.8” x 11.8” x 11.8”) |

| Standard lead time | 6 business days |

| Dimensional accuracy | ± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) |

| Layer thickness | 100 μm |

SLA

SLA rapid prototyping service

Where visual applications require an injection mold-like, smooth surface finish and a high level of feature detail, the SLA technology is most suitable.

| Standard capabilities | Description |

|---|---|

| Maximum build size | 145 × 145 × 175 mm (5.7" x 5.7" x 6.8") |

| Standard lead time | 6 business days |

| Dimensional accuracy | ± 0.5% with a lower limit of ± 0.15 mm (± 0.006") |

| Layer height | 25-100 um |

FDM

FDM rapid prototyping service

FDM is ideal for prototyping for form-fit testing purposes. FDM is the most cost-effective 3D printing technology and is available in 12 different materials.

| Standard capabilities | Description |

|---|---|

| Maximum build size | 500 x 500 x 500 mm (19.68’’ x 19.68’’ x 19.68’’)* |

| Standard lead time | 4 business days |

| Dimensional accuracy | ± 0.5% with a lower limit on ± 0.5 mm (0.0196’') |

| Layer height | 100-300 μm |

| Infill | 20-100% |

CNC

CNC-based rapid prototyping

CNC machining is the most efficient rapid prototyping method for producing uncomplicated metal parts, particularly when dimensional precision is essential.

| Standard capabilities | Description |

|---|---|

| Processes | Milling (3-, 4- & 5-axis) and turning |

| Materials | 35 metals and plastics, plus we’re always adding new ones |

| Finishes | Smoothed, bead-blasted, anodized, powder-coated, electropolished, brushed and more |

| Tolerances | Down to +/-.0008” (0.020mm) |

| Minimum order | $150USD |

| Lead times | 5-15 days |

CNC

Additional 3D printing rapid prototyping services

We provide a total of six distinct 3D printing technologies for rapid prototyping. These vary from low-cost and high-speed technologies to technologies that are more suitable for functional testing purposes.

| Standard capabilities | Description |

|---|---|

| Fast, low-cost prototyping | FDM, SLA and Polyjet |

| Functional prototyping | SLS and MJF |

| Materials | 25+ plastics |

| Standard lead times | 4-9 days |

Get an instant rapid prototyping quote

Get a rapid prototyping quote now! Experience fast and efficient manufacturing with 3D printing, CNC machining, and more. Transform your ideas into tangible prototypes quickly. Request a quote today and unlock the power of rapid prototyping!