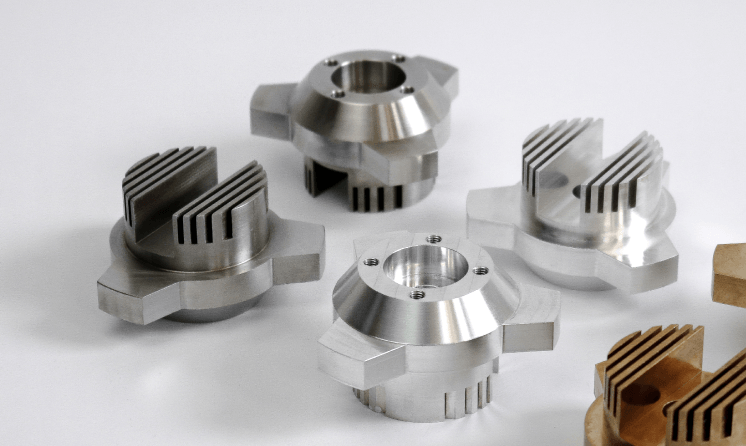

Surface finishing service

The most convenient method to acquire custom parts with a choice of 15+ surface finishing options. Obtain the bead-blasted, anodized, or powder-coated parts you require.

Our Surface Preparation Services

We offer various surface treatments to choose from, depending on the operational needs of your 3D printed or CNC machined components. Sandblasting removes printing marks and enhances the appearance; polishing creates a mirror finish, and the use of different coatings offers colour to parts, as well as protects them from rust and corrosion. We additionally offer anodising and plating services to boost the hardness and wear resistance of the parts. The performance and durability of the components can be extended, and their appearance improved, after undergoing surface treatment. With our advanced automated surface treatment equipment and extensive expertise, we can efficiently process your orders on schedule. Please contact our customer service to receive further information.

| Category | Applicable to | Processing Trace | Appearance Effect | Color | Tolerance |

|---|---|---|---|---|---|

| Raw Machined Surface | Metal, Plastic | Visibly slight surface scratches | None | N/A | Tolerance unaffected |

| Smooth Machined Surface | Metal, Plastic | Visibly slight surface scratches | None | N/A | Tolerance unaffected |

| Fine Machined Surface | Metal | Slightly visible | None | N/A | Tolerance unaffected |

| Polished Surface | Metal | Removed on the main surface | Consistently maintains appearance | N/A | Measured after polishing |

| Sandblasted Surface | Metal | Non-appearance removal on the main surface | As per requirements | N/A | Unaffected, except for specific features* |

| Brushed Surface | Metal | Non-appearance reduction, removal on the main surface | As per requirements | N/A | Measured after brushing |

| Anodized Type II | Aluminum | Non-appearance reduction, removal on the main surface | As per requirements | Black, Transparent, Red, Blue, Gold, Orange | Measured after anodization |

| Anodized Type III | Aluminum | Visible under anodization | None | Black, Natural | Measured after anodization |

| Black Oxide | Copper, Stainless Steel, Alloy Steel, Tool Steel, Mild Steel | Visible | None | Black | Measured after coating |

| Chromate Conversion Coating | Aluminum | Visible | None | Transparent | Measured after coating |

| Bare Nickel | Mild Steel, Aluminum, Stainless Steel | Reduced but visible | None | Metallic color (semi-bright) | Measured after bare nickel |

| Powder Coating | Metal | Removed | None | Black, White, RAL/Pantone color codes | Measured before coating |

| Brushing + Electropolishing | Stainless Steel | Removed on the main surface | Consistently maintains appearance | N/A | Measured after electropolishing |

Cosmetic surface finishes

Surface finishes can serve either a functional or aesthetic purpose, depending on the requirement. Surface finishes that serve both purposes are considered cosmetic surface finishes, which are used for parts with cosmetic purposes. The production of cosmetic parts requires taking additional measures to minimize defects, such as hang marks and scratches caused by tools.

Functional

Primary marks from machining will remain visible

- In its machined state

- Polished machining

- Precision machining

- Chromate conversion coating

- Electroless nickel plating

- Hardcoat anodized, type III

- Powder coating

- Black oxide

Cosmetic on request

Finishes can either be cosmetic or non-cosmetic, based on the request.

- Brushed finish with Anodizing type II.

- Bead blast finish with Anodizing type II.

- Bead blasted finish.

- Brushed finish.

Aesthetic by default

These finishes will always have an aesthetic purpose

- Brushed and electropolished

- Polishing process

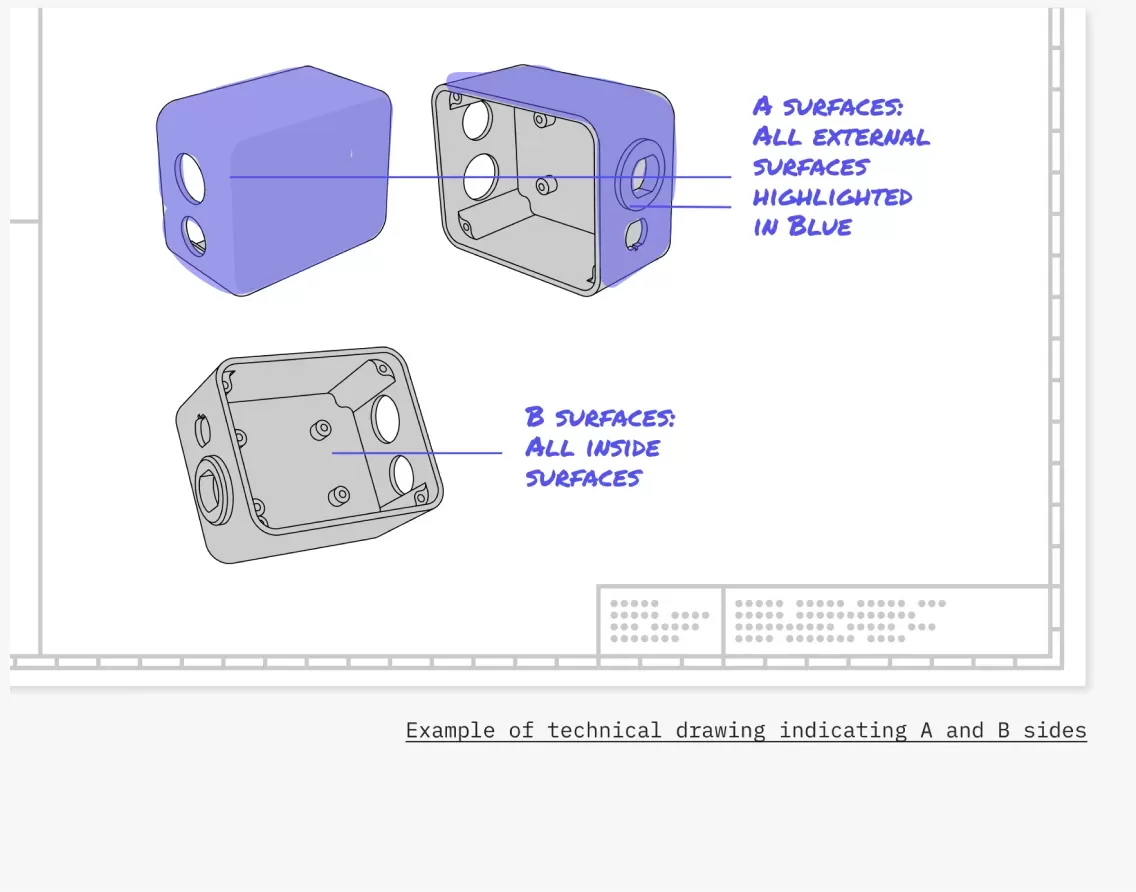

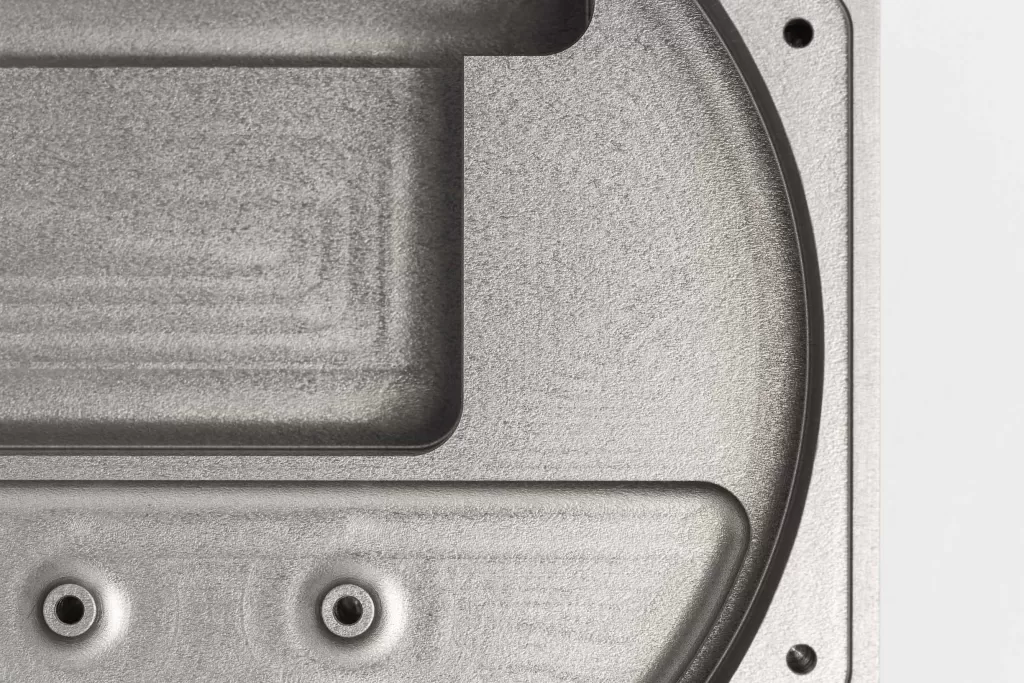

Defining an A-side and a B-side

Surface finishing frequently leaves cosmetic flaws on your components, such as hang marks for anodizing. Defining an A-side and a B-side in your design will ensure that the most crucial parts of your component remain defect-free.

This image shows how you can define an A-side and a B-side in your technical drawing:

A-side: Indicates the most aesthetically significant surface, generally the visible side of your product.

B-side: Indicates the side that is not aesthetically significant, generally the side hidden from sight after assembly.

We guarantee defect-free production for the primary surface (A-side) of your part. However, it is possible for the secondary surfaces (B-side) to have hanging marks and other minor defects as they are being machined. Like the rest of your part, the B-side surfaces will be free of scratches, stains, and blemishes.

| Will my part have | Surface | |

|---|---|---|

| Primary surface (A-side) | Secondary surface (B-side) | |

| Scratches, stains, blemishes | No | No |

| Hanging marks | No | Minor hanging marks |

| Other minor defects | No | Up to 2 minor defects |

Criteria for Cosmetic Acceptability

All cosmetic components manufactured by V1 comply with our Cosmetic Acceptability Criteria.

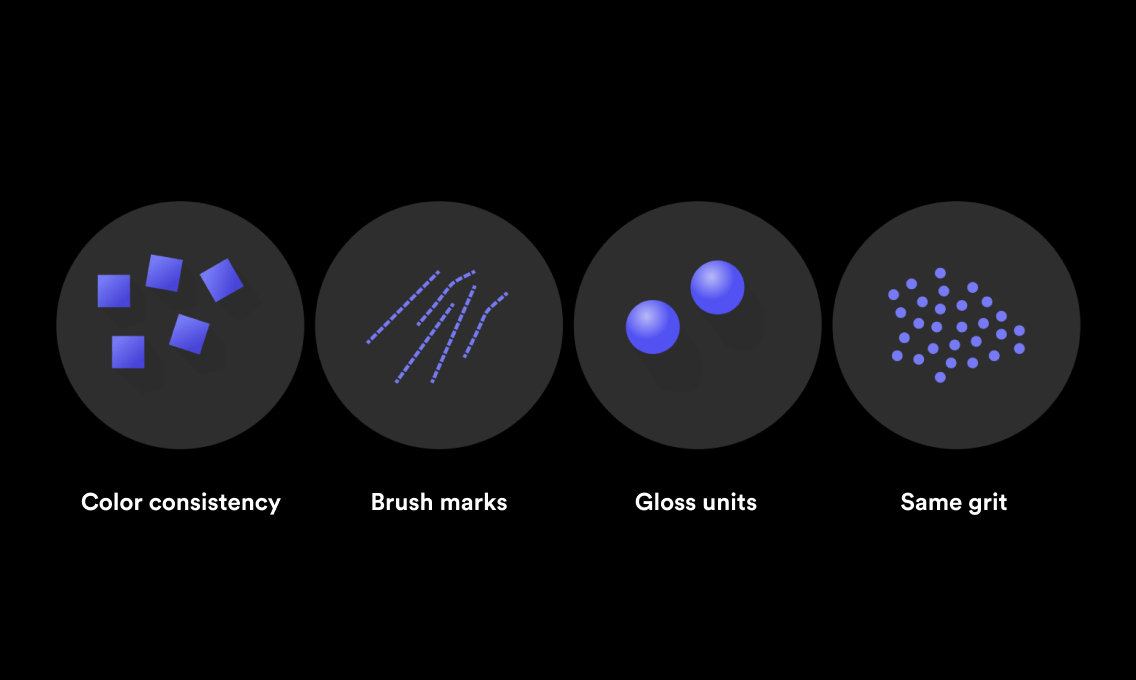

Requirements for Consistency

Visual consistency is required for each part within the same batch. This means that,

- Parts must be sanded or brushed with the same grit across the batch.

- Brush marks must be in the same direction for all parts.

- The colour must remain consistent to the same Pantone code when parts are positioned next to each other.

- The gloss units must be consistent throughout the batch.

** Manual brushing marks must be as unidirectional as possible. Please note that for rounded geometric shapes, the brushing marks may not be entirely unidirectional.

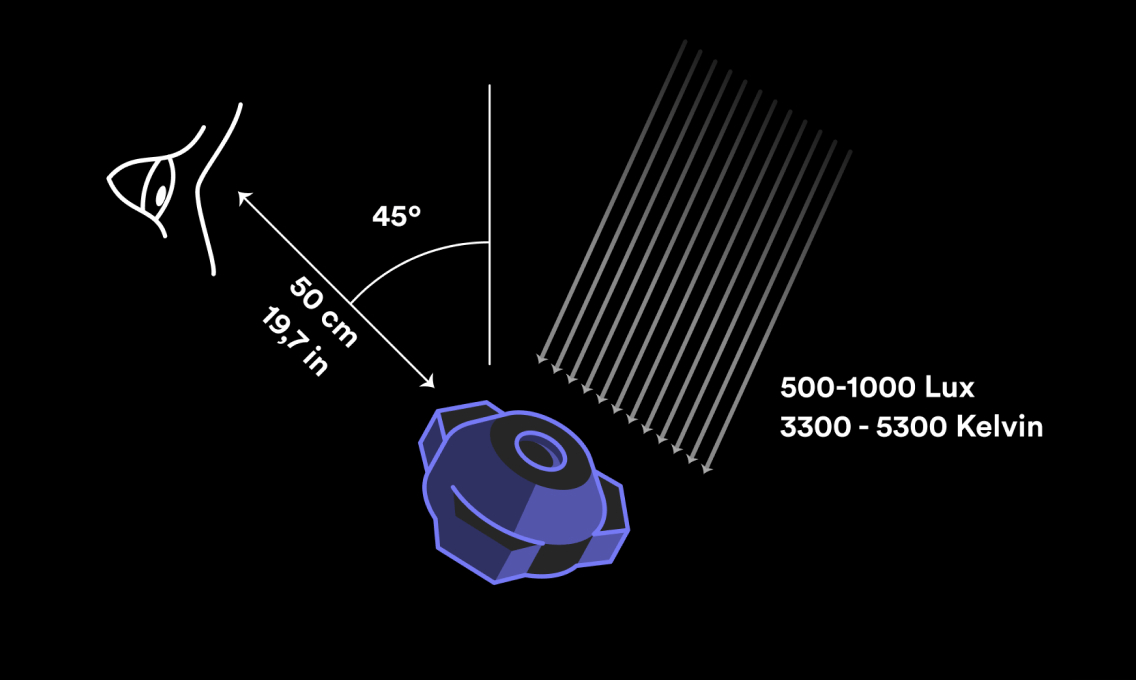

Conditions for visual inspection

Every part's surface quality must satisfy the following conditions:

Distance: 50cm ±10cm (19,7 inches ± 3,9 inches) with 20/20 vision (or corrected) should be maintained.

Angle of incidence: Around 45º from all directions

Conditions of lighting: 500-1000 Lux, with a neutral white color (3300-5300 Kelvin)

When you opt for our decorative surface preparation service, you will receive the following benefits:

- We guarantee higher surface quality standards, eliminating defects on the A-side and minimizing them on the B-side.

- Our service ensures a high degree of consistency in terms of colour, feel, and other aspects between parts within a batch.

- We conduct batch sampling inspections stringently to minimize the risk of quality issues.

- Our impeccable quality assurance system ensures that each component meets the expected standards.

Decorative surface treatment is preferable to ordinary surface treatment for parts that are frequently touched or viewed from many angles. This treatment will significantly improve the appearance and texture of your products.

Put your parts into production today

Our state-of-the-art manufacturing facilities allow fast and affordable production of your custom parts and components. Get your innovations to market faster while saving on costs. Contact us today to get a quote and put your designs into production within 1 week!