Elevate Your Industrial Machinery with Custom Parts

Harness the power of our diverse range of manufacturing technologies, including CNC machining, 3D printing, and sheet metal fabrication, to create custom parts that meet your specific needs. With a wide selection of materials available, you can achieve optimal performance and durability for your industrial machinery.

Produce high-quality components for industrial machinery

V1 is your complete solution for quickly sourcing competitively priced industrial-grade complex parts. Our instant quoting platform simplifies the process of prototyping, validating technologies, and producing larger volumes of parts—everything you require to keep your machines running flawlessly. All parts meet our stringent quality control requirements, and our approved supplier network offers you access to industry-leading capabilities and almost limitless capacity.

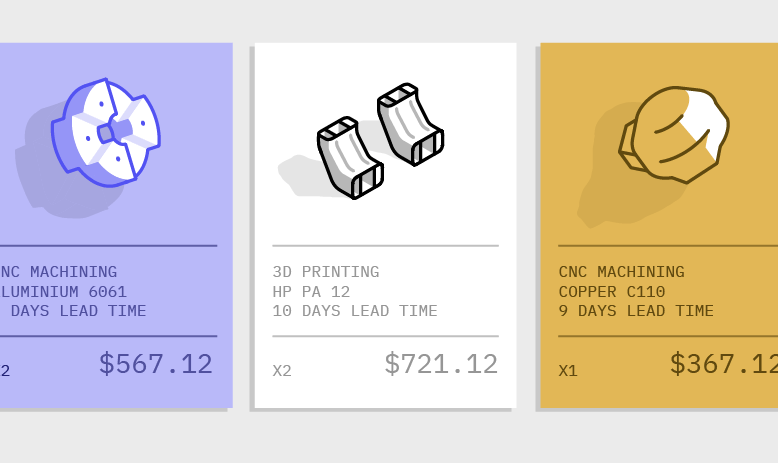

Immediate quotations and DFM assistance

Easily obtain pricing and lead times for unlimited complex parts.

- Confirm a price within seconds.

- Handle numerous iterations of bespoke components.

- Upload various designs to compare pricing options.

- Get immediate DFM guidance

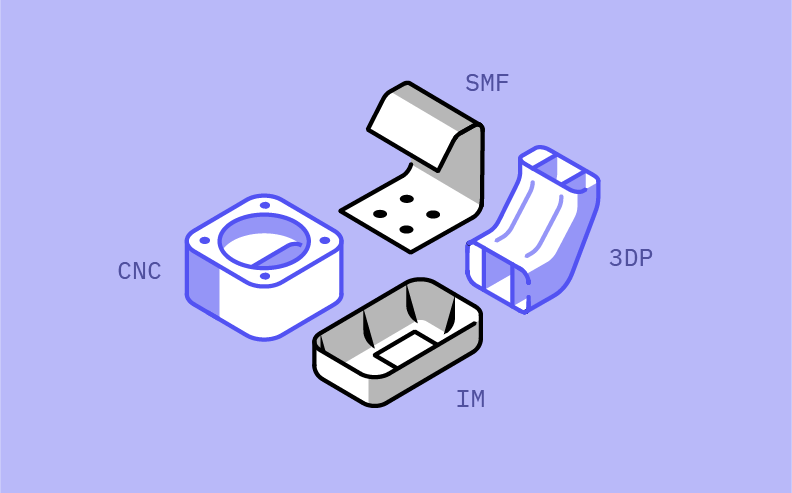

Extensive capabilities

Gain access to a wide range of technologies that enable the production of both complex and simple parts that form the backbone of machines.

- These include but are not limited to: CNC machining, sheet metal fabrication, and 3D printing.

- We offer a choice of over 50 metal and plastic materials.

- Customizable surface finishes are available as an option.

- V1 is certified to the ISO 9001 standard, and our MPs possess additional certifications.

Discover the appropriate process for your project.

Rapid manufacturing

Since every underused machine incurs a cost for you. Our quick and effortless service ensures timely optimisation of your machinery.

- Delivered on time and according to specifications, consistently.

- We offer both local and global CNC machining options with lead times as short as five days.

- Order parts in small or large quantities

Produce components using V1 Local.

We offer local manufacturing with a lead time of 5 days

Local machining options available for your CNC parts. We provide US and EU customers with the option of local or global manufacturing. This helps in faster delivery of parts. This enables manufacturing within your customs-clearance zones, reducing logistical hurdles and leading to faster delivery times.

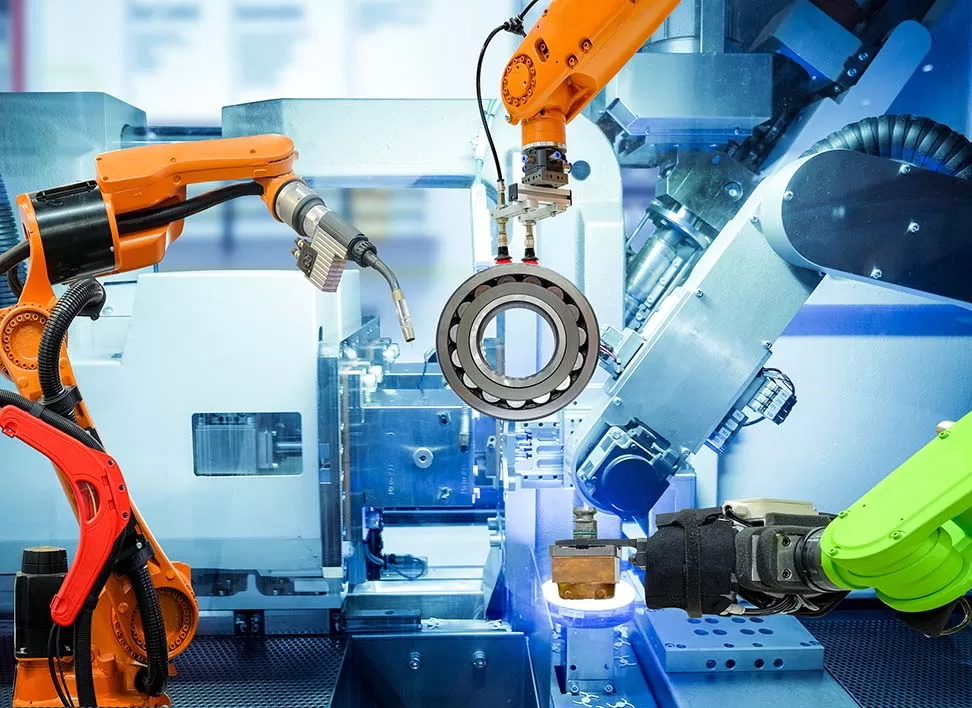

How machinery parts manufacturers use V1

- Moving parts

- Casings

- Conveyor belts

- Industrial jigs & fixtures

- Automation parts

- Replacement parts

- Prototyping

- Price estimates

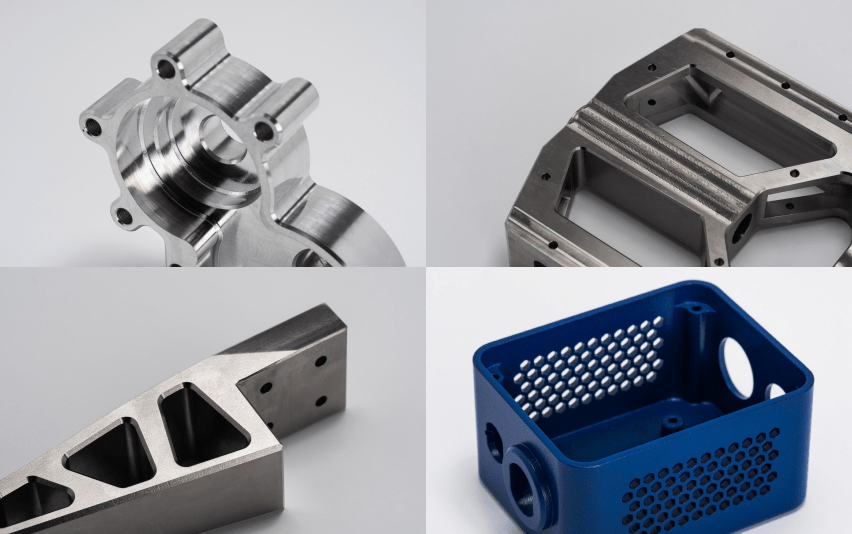

Industrial machinery manufacturing capabilities

CNC milling

For cost-efficient prototypes and production

- 3-, 4- & 5-axis milling

- Lead times from 5 business days

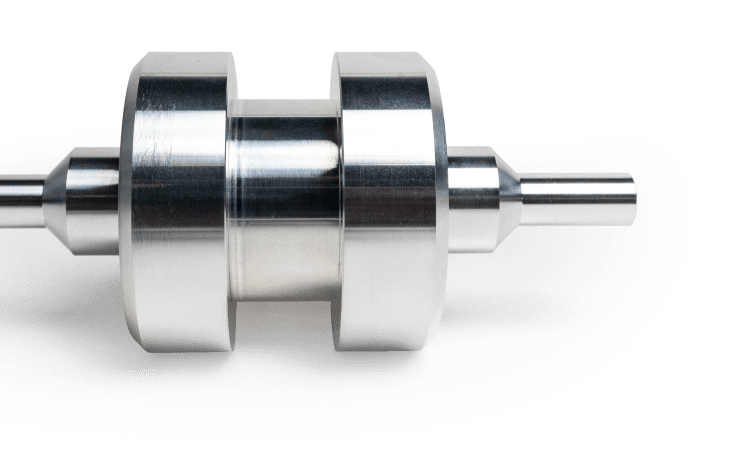

CNC turning

Lathes and live tooling ideal for cylindrical parts

- 60+ metals & plastics, including 10+ aluminum & 20+ steel

- Lead times from 5 business days

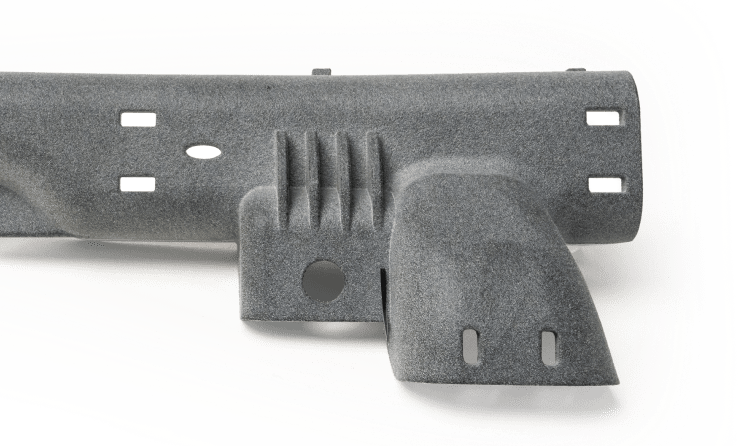

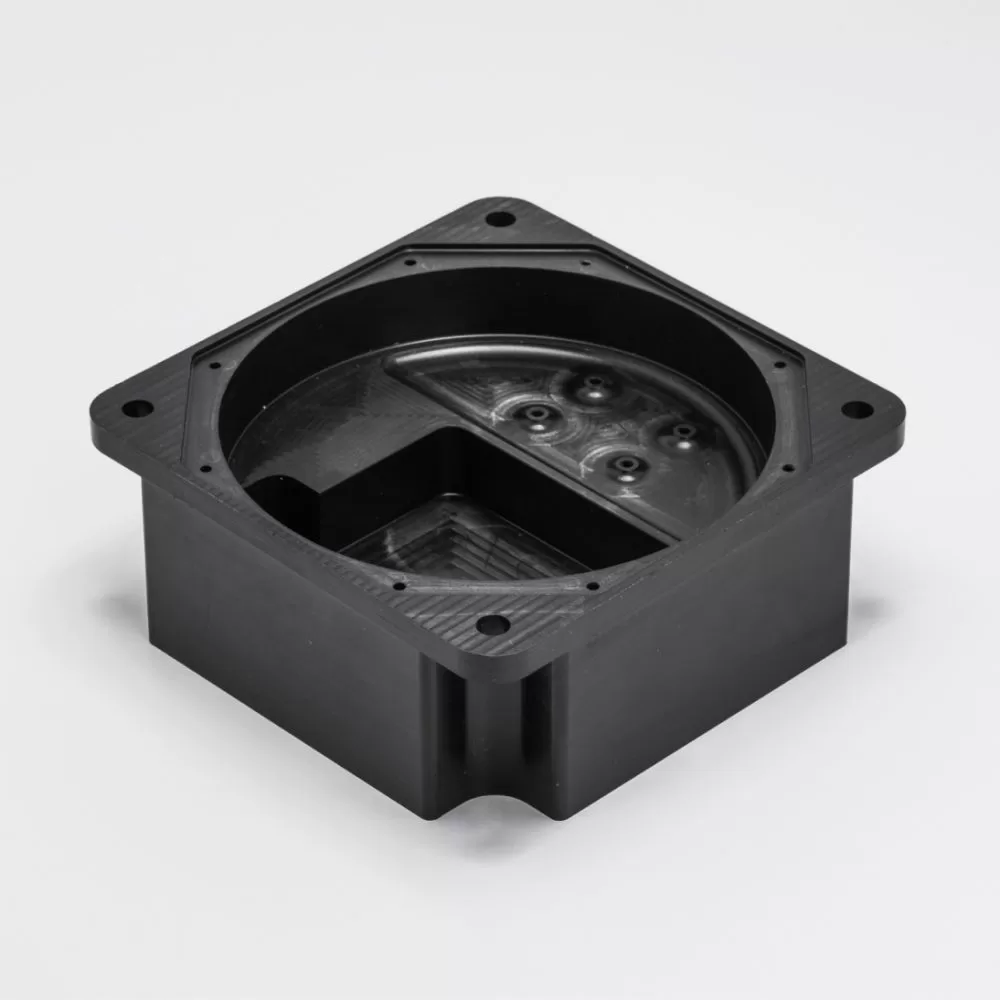

3D printing

FDM, SLA, SLS, MJF,SLM

- 25+ plastics & 35+ colors

±0.5% dimensional accuracy with a lower limit down to ±0.59” (0.15 mm) - Lead times from 1 business day

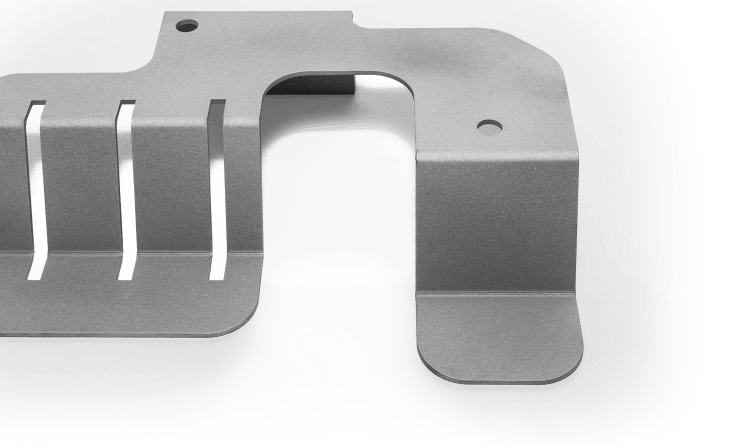

Sheet metal fabrication

Laser-cutting, bending, post-processing

- Tolerances down to 0.10 mm (0.004 in)

- Lead times from 5 business days

Why machinery experts use V1

Specialized network

Get access to cutting-edge capabilities and limitless capacity at the highest standard

Quality assurance

Dimensional checks with calibrated equipment, material data sheets and industry certifications

DFM support

Lower the cost of your order with immediate manufacturability feedback

Materials and surface finishes for mechanical parts used in industry

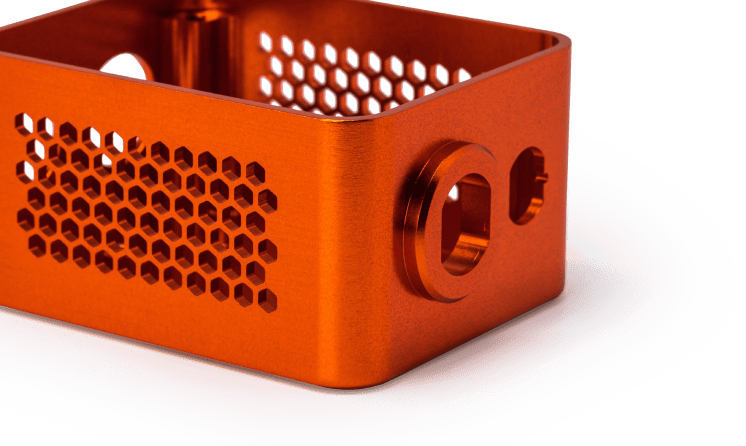

Our partner manufacturing network provides access to durable and lightweight materials with high-quality surface finishes that can withstand any application.

Materials for industrial machinery

Select from over 30 metal alloys and hundreds of industrial-grade plastics.

Steel and stainless steel options include 303, 316/316L, 15-5, Tool Steels, 4140, and 1.7225.

Aluminum options consist of 6061-T6, 6082, 7075-T6, 5083-H111, and 2017.

Brass and Copper alloys are also available. C360, Copper C110, and Copper C101

Thermoplastics include: Polyoxymethylene (POM), PEEK, and PET

Commodity polymers include: Polyethylene (PE), Polypropylene (PP), and PVC

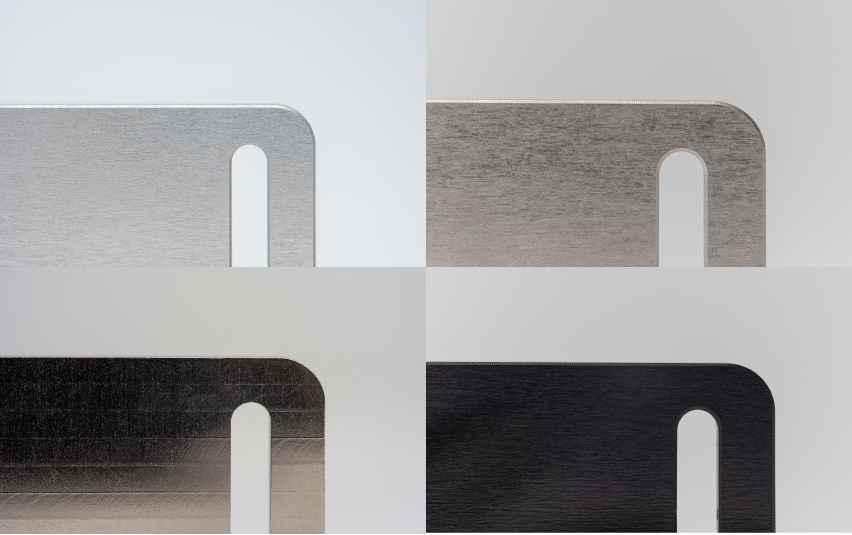

Surface finishes for industrial machinery

Enhance durability and performance through a range of surface finishes

Anodisation

Electroless nickel plating process

Black oxidation process

Conversion coating with chromate

Coating with powder

Passivation

Installation of inserts

Thermal treatment

Further industrial manufacturing services

The capabilities of V1 go beyond what is available on the platform. We can manufacture everything your machines need to complete the job, from rapid mechanical prototyping with 3D printing to casing creation with injection molding or production of intricate components using electrical discharge machining (EDM). If you require further details about our supplementary services, please contact us at 3dprinting@V-1.com.

Gallery of industrial mechanical parts

Innovating with V1: How it Benefits Industrial Machinery Companies

We offer competitive pricing, prioritize IP protection, and provide DFM guidance

The V1 platform provides the most convenient and competitive method to compare prices for different order volumes, lead times, materials, tolerances, secondary processes, and other project requirements. Obtain all pricing information upfront, including shipping, quality control, and customs clearance (for orders from the US and EU). We prioritize IP protection throughout our platform and process to guarantee complete security for your designs and models. Our platform is equipped with design for manufacturability (DFM) analysis. Our team of mechanical engineers is constantly available to provide guidance on how to maximise the benefits of using V1.

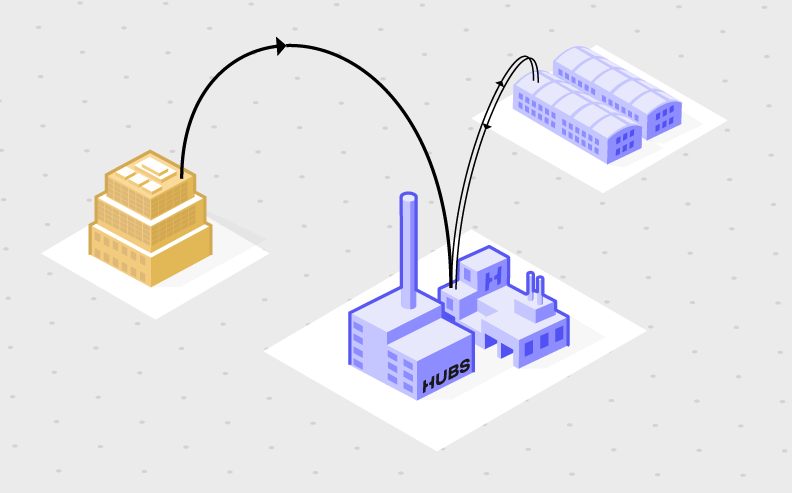

Meeting specification and delivery deadlines, consistently

We maintain a consistent and reliable supply chain by adhering to rigorous quality control processes and protocols. Our manufacturing partners go through a complete vetting process before joining the network and on-site quality engineers perform frequent audits to ensure they meet the V1 Standard. Our in-house teams in Amsterdam and Chicago conduct inspections to verify functional and cosmetic specifications of parts, while we manage all customs clearance requirements and ensure timely delivery.

To reduce the risks in your supply chain, we source both locally and globally

Supply chain resilience is crucial, particularly when you require parts on a strict schedule with specific certifications. Our local and global sourcing options reduce the risks in your supply chain, and we provide sourcing solutions to ensure regulatory compliance. V1 provides access to an extensive network of industrial 3D printing, CNC machining, injection molding, and sheet metal experts, with consistent capacity available for industrial equipment projects of any scale.

FAQ's

We conduct comprehensive checks of each manufacturing partner (MP) during the onboarding process and carry out audits of their processes and certifications every two years. To procure parts from certified manufacturers, you may specify the requirements on the platform or get in touch with us at 3dprinting@v-1.com. We will match your designs with the most appropriate supplier.

Our platform guarantees the security and encryption of all customer data and supplier interactions. Digital models and drawings are safely stored on European-based AWS servers. Our Manufacturing Partner Agreement is mandatory for MPs to sign as part of their onboarding process, committing them to the confidentiality of customer data. Our General Terms of Sale prohibit orders which infringe on copyrights, patents, design rights, trademarks, trade secrets, or any other type of intellectual property rights.

Engineers use V1 partly because we assume all the risks on your behalf. In case your parts do not meet the required specifications, you may file a dispute claim and we will either remake the components or refund your order. For further details on how we manage disputes, please contact our Customer Success Team. At the same time, we generate non-conformity reports for parts that fail to meet all requirements and offer follow-up with manufacturers, including root cause analysis and rapid corrective actions.

To obtain parts made from specialized materials that are not included on our site or platform, you may submit a request to your account manager or contact us at 3dprinting@v-1.com. Our supplier network has access to a vast range of materials, enabling us to find a manufacturing partner to fulfill most of your requests.