Our Aluminum Anodizing Services offer a reliable solution to improve the durability, corrosion resistance, and aesthetic appeal of your aluminum parts. With our advanced anodizing processes, we create a protective oxide layer on the surface, providing enhanced protection and customization options for your components.

Anodizing type II

| Surface preparation | Colors | Glossiness | Cosmetic availability | Thickness** | Visual appearance |

|---|---|---|---|---|---|

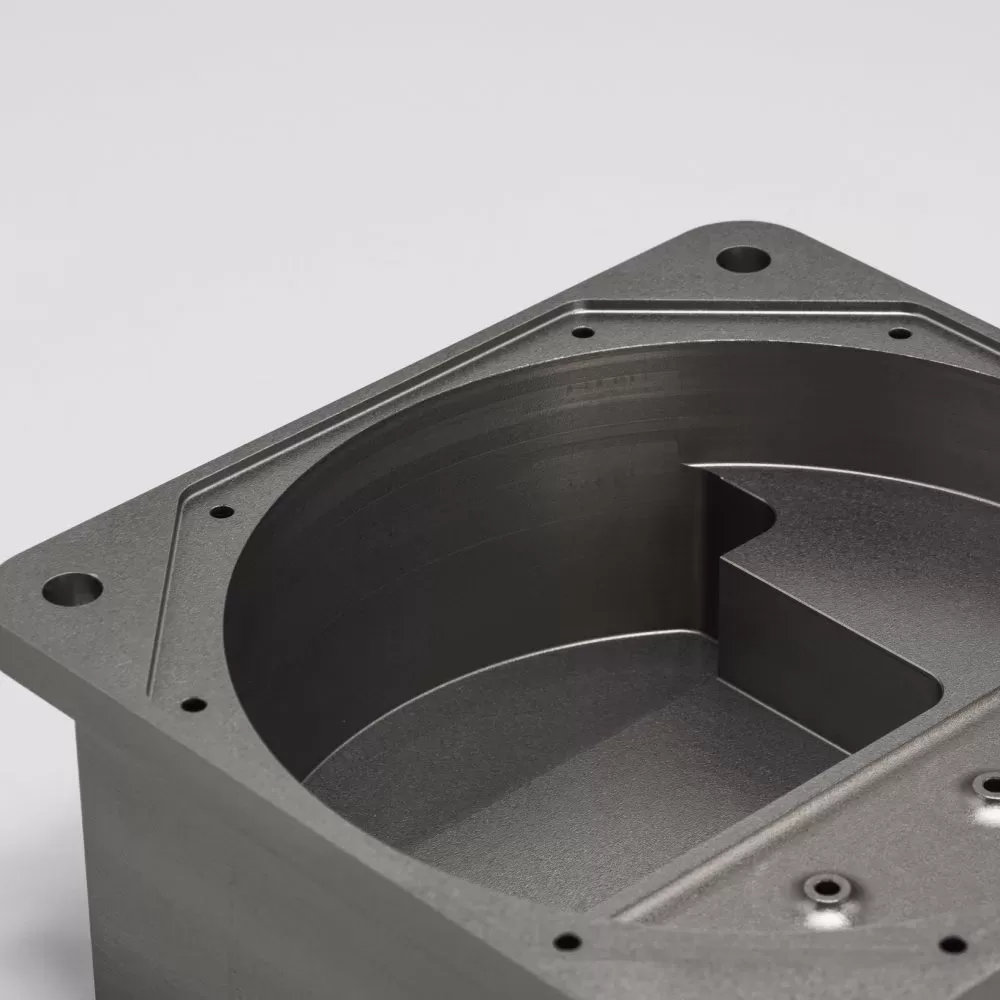

| As machined (Ra 3.2μm / Ra 126μin) | Clear, Black, Red, Blue, Orange, Gold | Glossy (Above 20 GU) | No | 50μm to 150μm | Parts are anodized directly after machining. Machining marks will be visible. |

| Bead blasted | Clear, Black, Red, Blue, Orange, Gold | Matte (Below 10 GU) | Cosmetic on request | for clear: 8 to 12μm(0.0003” to 0.0004”) black and color: 12 to 16μm(0.0004” to 0.0006”) | Grainy texture, matte finish |

| Bead blasted | Clear, Black, Red, Blue, Orange, Gold | Glossy (Above 20 GU) | Cosmetic on request | for clear: 8 to 12μm(0.0003” to 0.0004”) black and color: 12 to 16μm(0.0004” to 0.0006”) | Grainy texture, glossy finish |

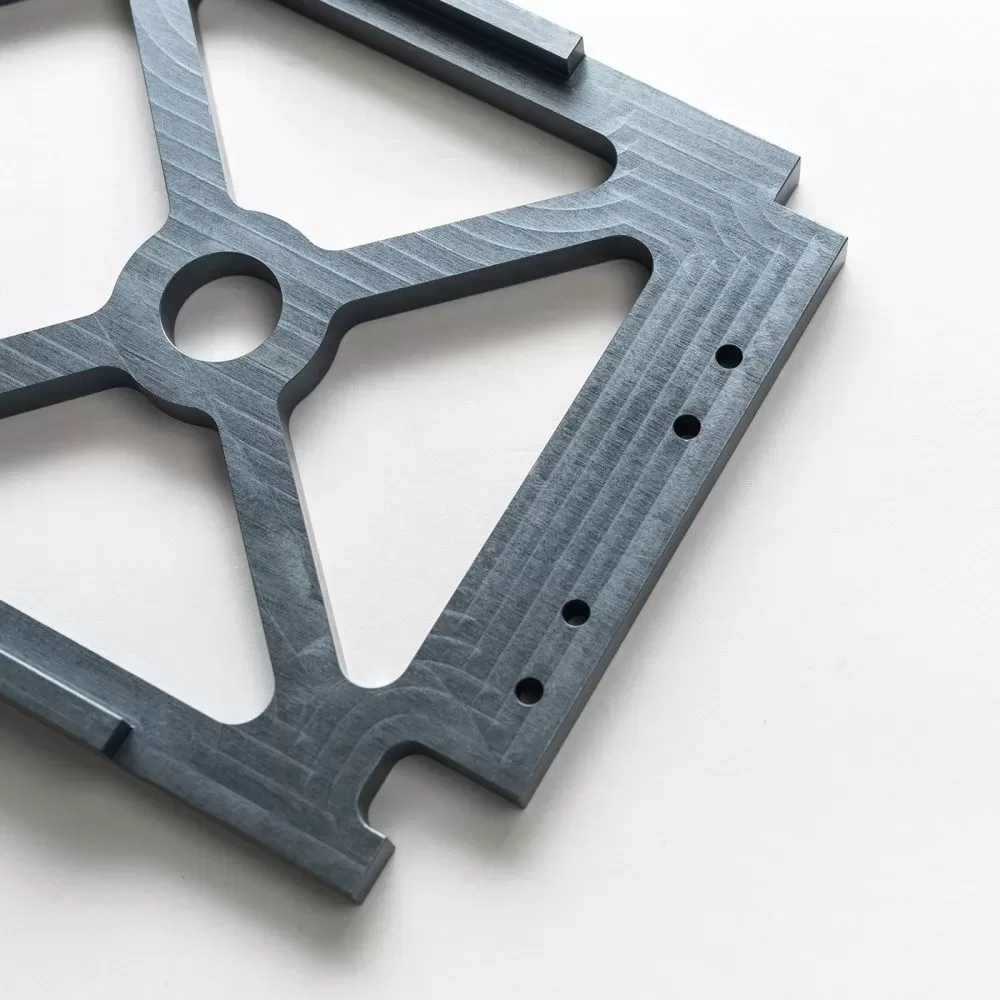

| Brushing(Ra 1.2μm / Ra 47μin) | Clear, Black, Red, Blue, Orange, Gold | Glossy (Above 20 GU) | Cosmetic on request | for clear: 8 to 12μm(0.0003” to 0.0004”) black and color: 12 to 16μm(0.0004” to 0.0006”) | Parts are manually brushed to reduce marks, then anodized. Brushing lines will be visible. |

Anodizing type III

| Surface preparation | Colors | Cosmetic availability | Thickness | Visual appearance |

|---|---|---|---|---|

| As machined (Ra 3.2μm / Ra 126μin) | Black, Natural (thicker layers will appear darker) | No | 35 to 50μm(0.0013” to 0.0019”) | Parts are anodized directly after machining. Machining marks will be visible. |

| Bead blasted (Glass beads #120) | Black, Natural (thicker layers will appear darker) | Cosmetic on request | 35 to 50μm(0.0013” to 0.0019”) | Can be slightly visible if parts are “Not Cosmetic” Completely removed if parts are “Cosmetic” |

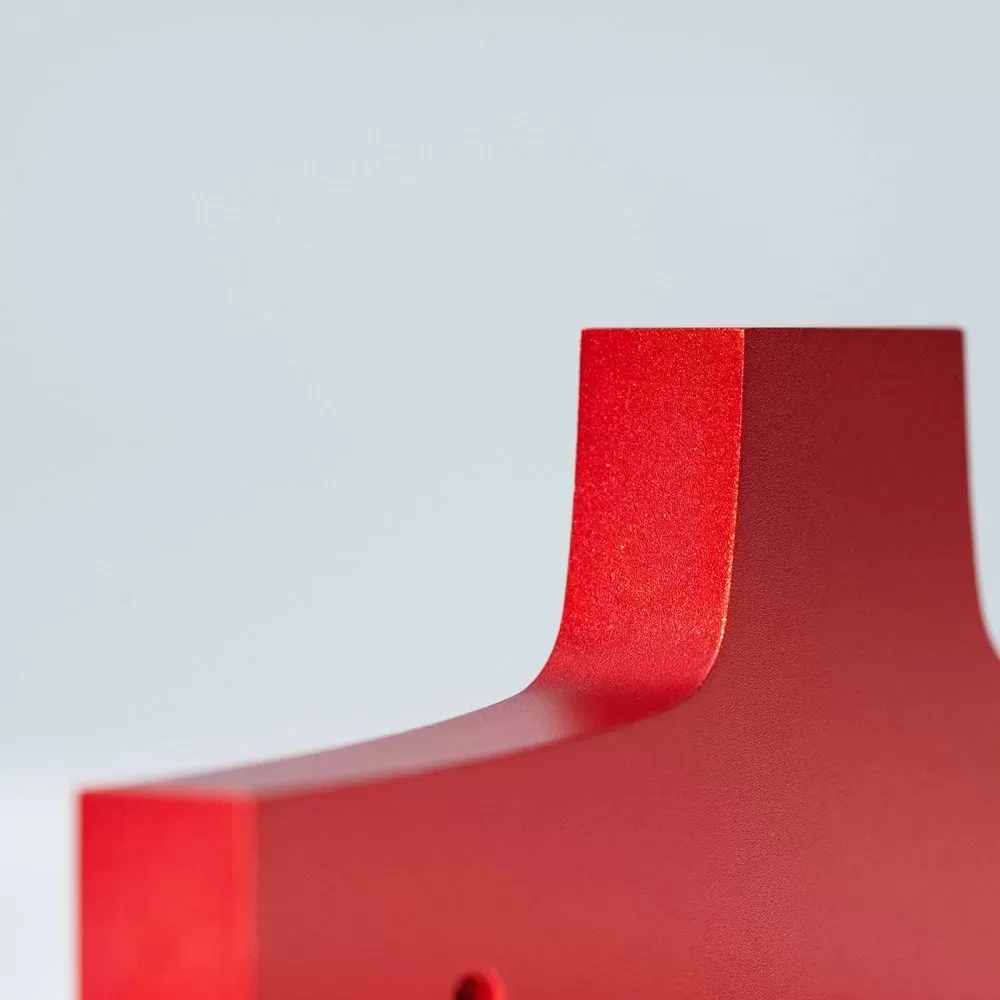

Color options for aluminum anodizing type II

Color anodizing can have some variation in color due to standard alloy tolerance variations. Check the color scheme below to see the color range.

Color options for aluminum anodizing type III

Why Choose Our Aluminum Anodizing Services?

- Superior Protection: Anodizing forms a durable oxide layer on the aluminum surface, significantly enhancing its resistance to corrosion, wear, and weathering. This protective layer ensures longevity and preserves the integrity of your parts, even in challenging environments.

- Customizable Finishes: Our anodizing services offer a wide range of color options and finishes, allowing you to customize the appearance of your aluminum parts. From vibrant colors to subtle hues, we can achieve the desired aesthetic effect, making your components visually appealing and on-brand.

- Precise Coating Thickness: Our skilled technicians employ precise control over the anodizing process, ensuring consistent coating thickness across your parts. This level of control guarantees uniformity and accuracy, meeting your specifications and quality requirements.

- Versatile Applications: Our aluminum anodizing services cater to various industries, including automotive, aerospace, electronics, and more. Whether you need anodized components for functional or decorative purposes, we can accommodate your specific application needs.

- Eco-Friendly Practices: We are committed to environmentally responsible practices. Our anodizing processes follow strict regulations, employing eco-friendly chemicals and minimizing waste generation. You can trust that our services are both efficient and sustainable.

- Expertise and Experience: With years of experience in the industry, our team has honed their skills in aluminum anodizing. We stay updated with the latest techniques and technologies, ensuring that you receive high-quality results and exceptional service.

- Quality Assurance: Quality is our top priority. We have robust quality control measures in place to inspect each anodized part thoroughly. This ensures that your components meet the highest standards of durability, aesthetics, and performance.

Gallery of anodized parts manufactured by V1

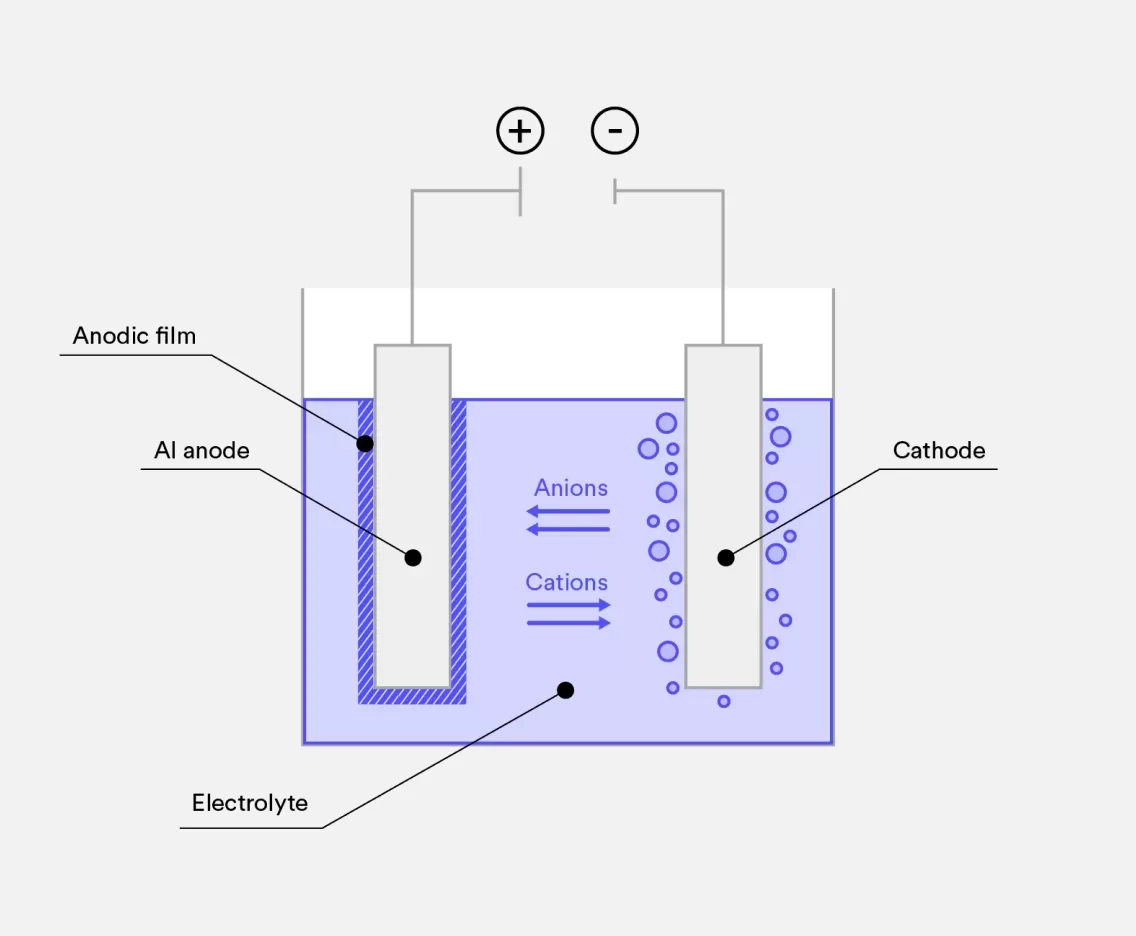

The Hubs anodizing process

Anodizing is an electrolytic process both for protecting aluminum parts against wear and corrosion and for improving cosmetic appearances. Let’s break down the basic steps for anodizing a part:

- Connect the part to an anode

- Submerge the part in acidic electrolyte solution

- Apply a cathode to a metal electrode in the solution

- Positive ions react with negative O2 ions and the surface becomes porous

- This grows a layer of aluminum oxide on the part

- Use corrosion inhibitors or colored dyes for cosmetic purposes

- Seal the nanopores

Experience the Benefits of Aluminum Anodizing

Unlock the full potential of your aluminum parts with our professional anodizing services. Enhance their durability, corrosion resistance, and visual appeal. Contact us today to discuss your project requirements and discover how our aluminum anodizing services can elevate your components to new heights.