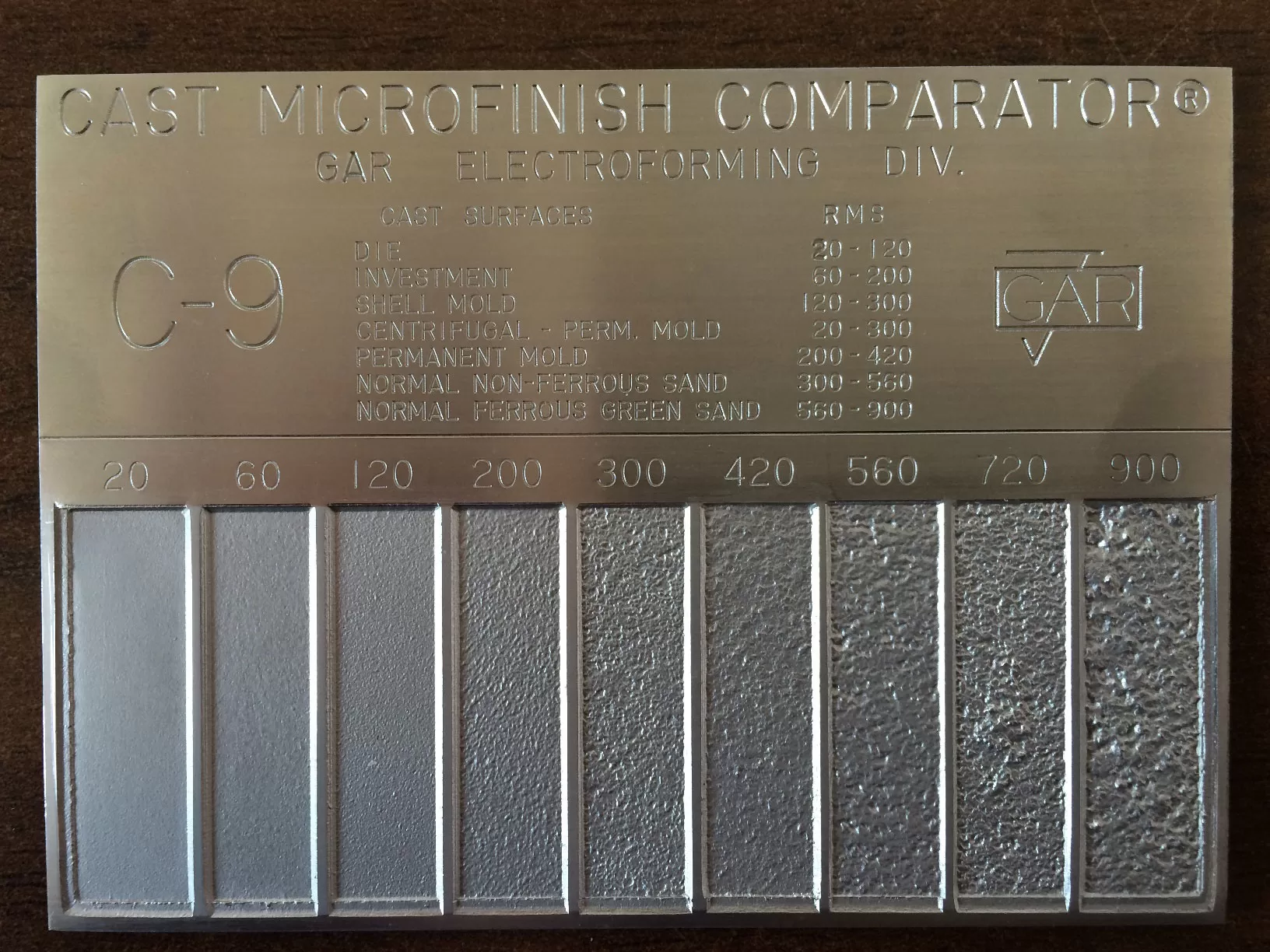

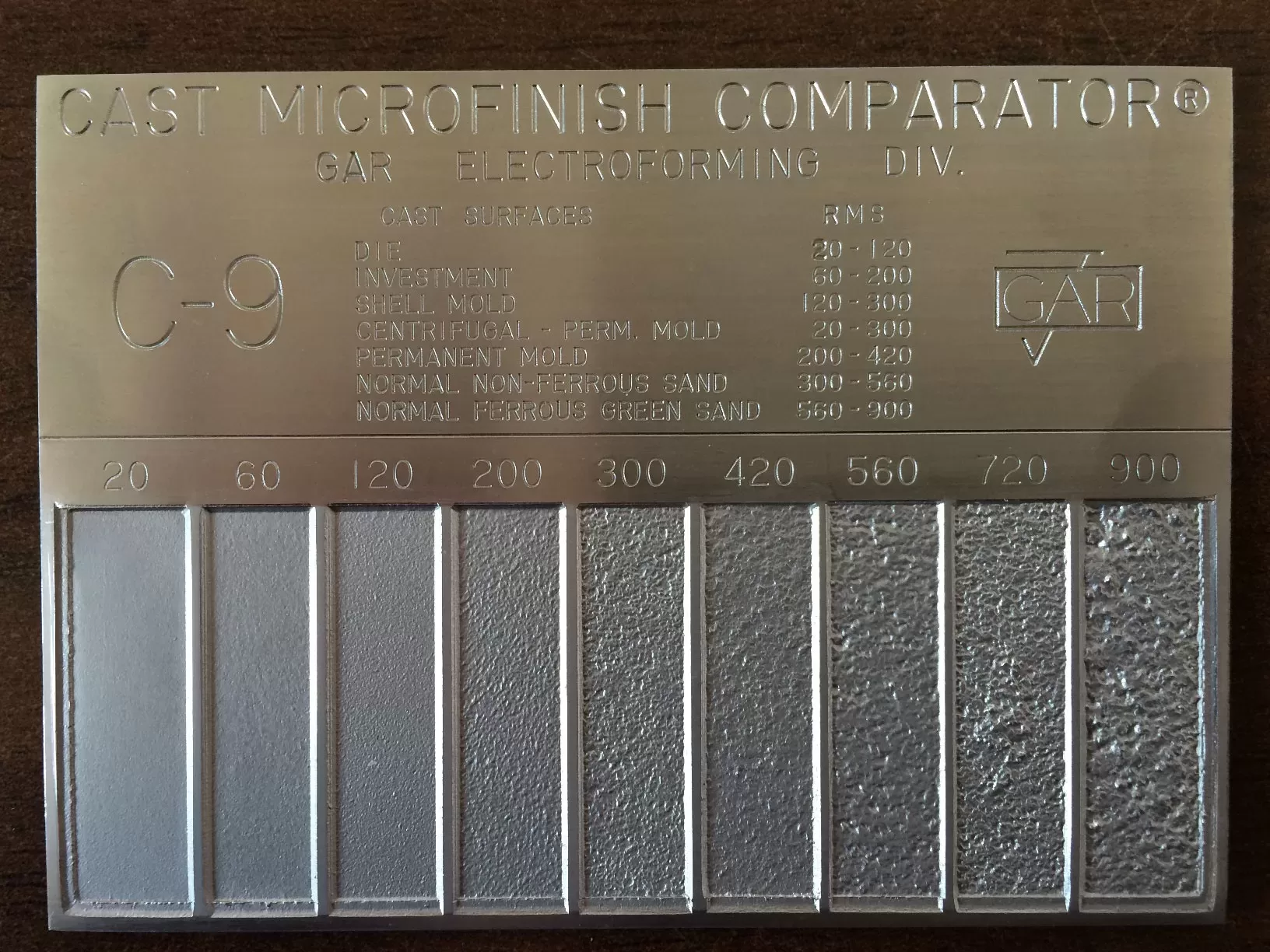

As machined surfaces typically have a slight roughness, which is caused by the tool marks left behind by the machining process. Surface roughness is measured in micrometers (µm) and is typically denoted by the symbol Ra. For example, an as machined surface with a Ra of 3.2µm would be considered to be relatively smooth.

The roughness of an as machined surface can vary depending on the type of machining process that was used. For example, milling typically produces a rougher surface than turning. The roughness of the surface can also be affected by the material being machined and the speed and feed rates of the machining process.

As machined surfaces are often used for parts that do not require a high level of precision or surface finish. For example, they are commonly used for structural parts, such as brackets and housings. As machined surfaces are also often used for parts that will be painted or coated, as the roughness of the surface can help to improve the adhesion of the paint or coating.

In some cases, as machined surfaces may be further processed to improve their surface finish. For example, they may be polished, ground, or honed. These processes can help to remove tool marks and produce a smoother, more uniform surface.

As machined surfaces are a cost-effective option for many applications. They are also relatively quick and easy to produce. However, they may not be suitable for applications that require a high level of precision or a smooth surface finish

| Surface roughness | Applicable materials | Cosmetic availability | Visual appearance |

|---|---|---|---|

| Ra 3.2μm / Ra 126μin | Metals, plastics | Not cosmetic | Machining marks are visible, light surface scratches are visible |

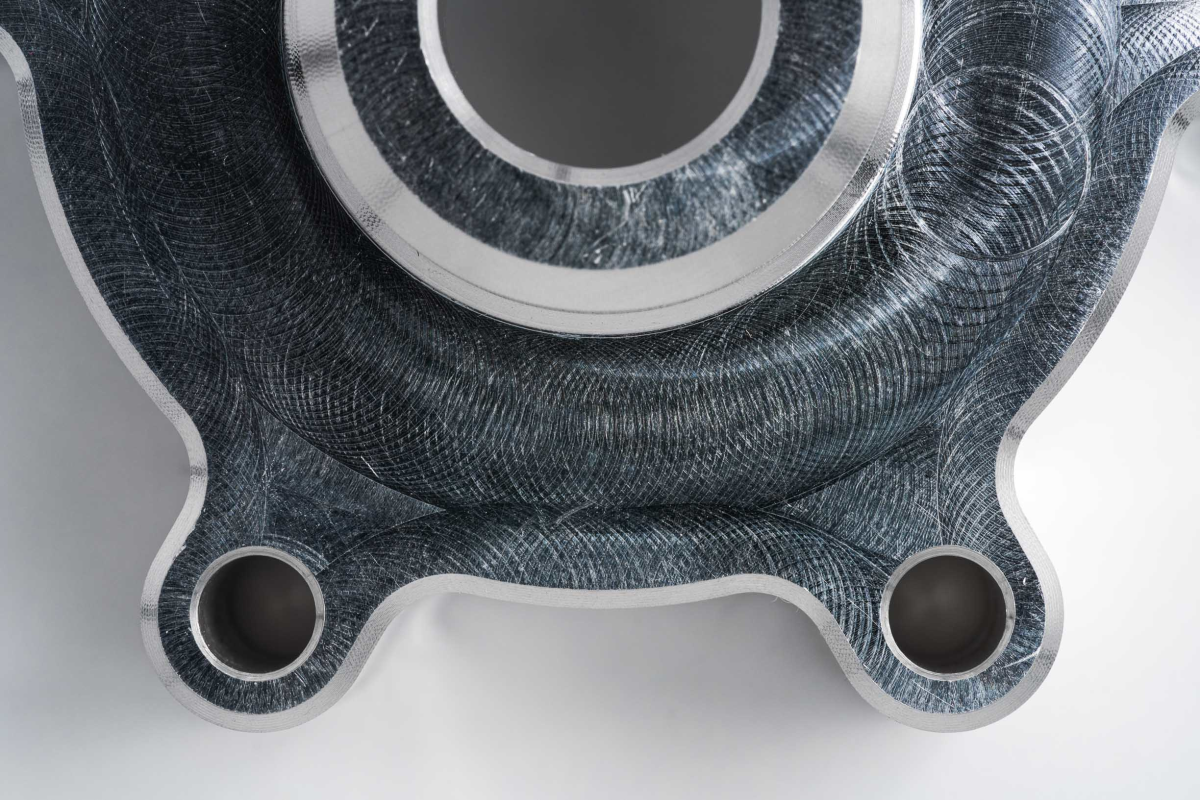

Example of an as machined part