Restore and Enhance with Bead Blasting Services

At V1, we offer professional bead blasting services to revitalize and enhance the appearance of your parts. Our specialized bead blasting techniques remove surface imperfections, rust, and coatings, leaving behind a clean and refreshed surface.

Why Choose Our Bead Blasting Services?

- Effective Surface Restoration: Bead blasting is a highly effective method for removing rust, corrosion, paint, and other coatings from various surfaces. Our skilled technicians use a precise combination of air pressure and fine abrasive beads to restore your parts to their original condition, revealing a clean and smooth surface.

- Versatile Applications: Our bead blasting services cater to a wide range of industries and materials. Whether you need to refurbish automotive components, clean metal surfaces, or prepare parts for further processing, our versatile bead blasting solutions can meet your specific requirements.

- Precision and Consistency: Our team is equipped with state-of-the-art bead blasting equipment that allows for precise control of air pressure and abrasive flow. This ensures consistent and uniform results across all parts, regardless of size or complexity.

- Surface Preparation: Bead blasting is an ideal surface preparation method before painting, coating, or bonding. By removing contaminants and providing a textured surface, bead blasting enhances adhesion, resulting in improved durability and longevity.

- Environmentally Friendly: We prioritize eco-friendly practices and use environmentally safe abrasive materials for bead blasting. Our methods comply with industry regulations and minimize the impact on the environment while delivering exceptional results.

- Custom Solutions: We understand that every project is unique. Our team works closely with you to understand your specific needs and develop customized bead blasting solutions. Whether you require a specific surface finish or have special considerations, we strive to exceed your expectations.

- Quality Assurance: Quality is our top priority. We have strict quality control measures in place to ensure that each part undergoes thorough inspection to meet the highest standards of cleanliness and surface quality. Your satisfaction is our ultimate goal.

Bead blasting specifications

| Applicable materials | Media | Cosmetic availability | Visual appearance |

|---|---|---|---|

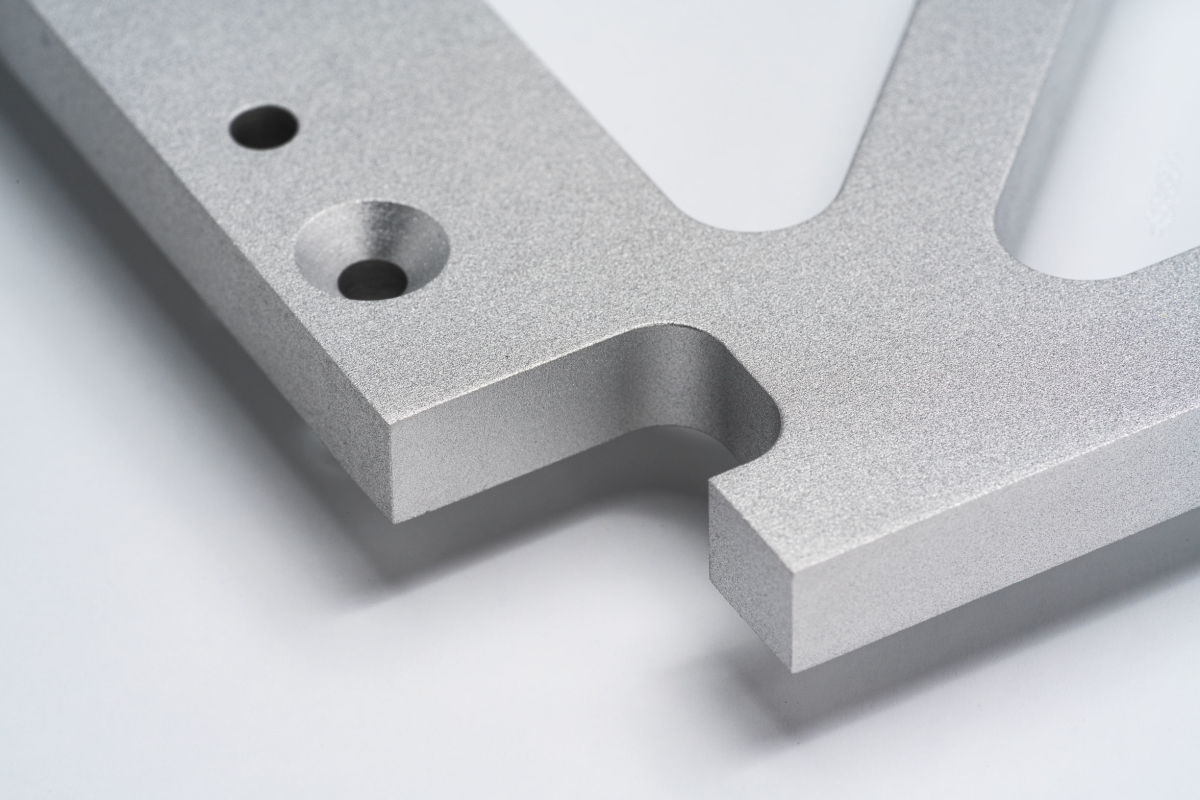

| Aluminum, Copper, Mild steel, Titanium, Brass, Alloy steel, Stainless steel, Tool steel | Glass beads with grit #120 | Cosmetic upon request | Grainy, slightly matte texture. Machining marks are reduced for “non-cosmetic” options and entirely removed on primary surfaces for “cosmetic” options. |

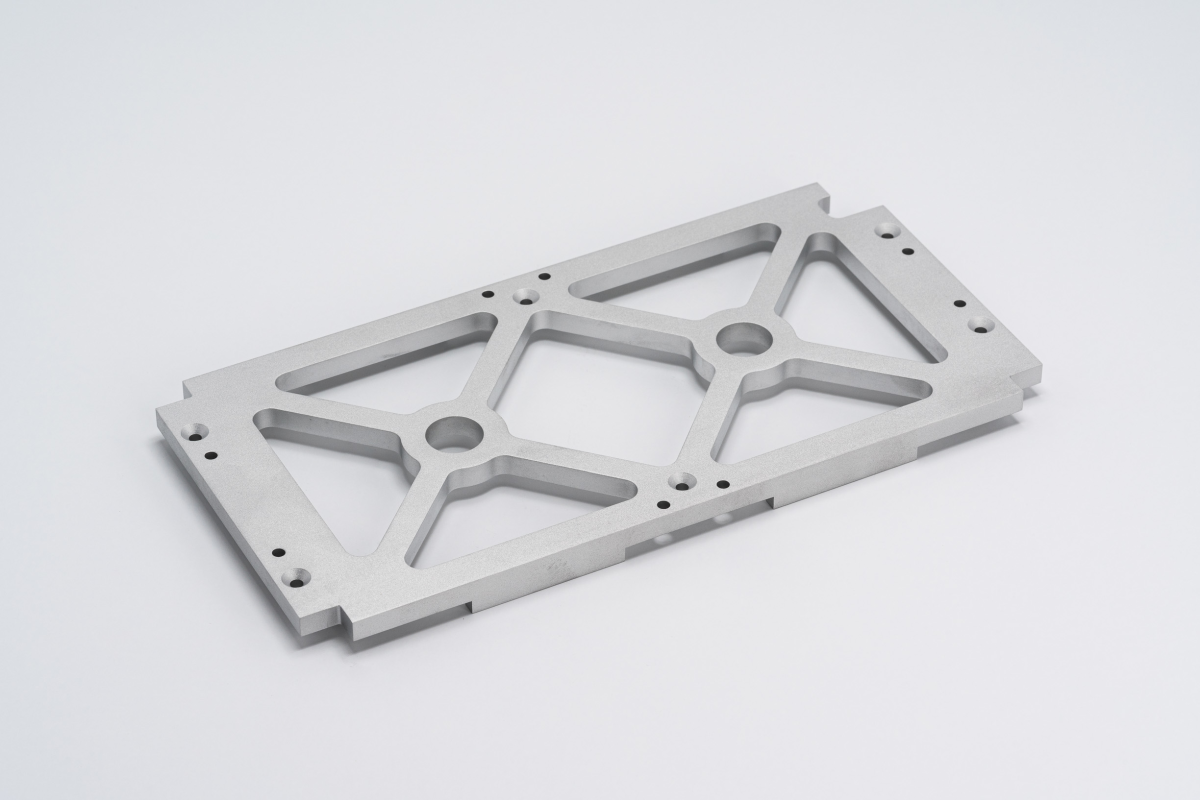

Example of a bead blasted part

Bead Blasting Service Options

| Service Features | Benefits |

|---|---|

| Effective removal of rust, coatings, and imperfections | Surface restoration and rejuvenation |

| Versatile applications for various industries | Improved adhesion for coatings and bonding |

| Precision and consistency across all parts | Environmentally friendly practices |

| Customized solutions for unique requirements | Rigorous quality control measures |

Experience the Difference

Restore the original beauty and functionality of your parts with our professional bead blasting services. Whether you need surface restoration, preparation for coatings, or cleaning of industrial components, our expertise and commitment to quality will deliver exceptional results.

Contact us today to discuss your project requirements and discover how our bead blasting services can transform your parts.