Electroless nickel plating is a process in which a uniform layer of nickel is deposited onto the surface of a substrate through a chemical reaction, without the need for an electric current. This process provides numerous benefits, including enhanced corrosion resistance, wear protection, and improved surface hardness for metal parts. It is widely used in industries such as automotive, aerospace, electronics, and manufacturing.

| Surface preparation | Tolerances | Cosmetic availability | Thickness | Visual appearance |

|---|---|---|---|---|

| Smooth machined (Ra 1.6μm / Ra 63μin) | Apply after Electroless nickel plating | No | 3μm to 40μm | Electroless nickel plated parts will have a smooth, semi-bright appearance. |

Design Considerations for Electroless Nickel Plating

When considering electroless nickel plating, the following design considerations should be taken into account:

- Surface Preparation: Ensure proper cleaning and preparation of the substrate surface to achieve optimal adhesion and coating quality.

- Dimensional Impact: Evaluate the impact of the plating thickness on critical dimensions and tolerances of the part.

- Substrate Material Compatibility: Electroless nickel plating is compatible with various metals, including steel, aluminum, copper, and their alloys. Verify the compatibility of the substrate material with the plating process.

- Functional Requirements: Determine the specific functional requirements, such as corrosion resistance, wear protection, or electrical conductivity, and communicate them to the service provider.

- Post-Treatment and Handling: Consider any required post-treatment steps, such as heat treatment or additional coatings, and ensure proper handling to maintain the integrity of the plated surface.

Example of an electroless nickel plated part

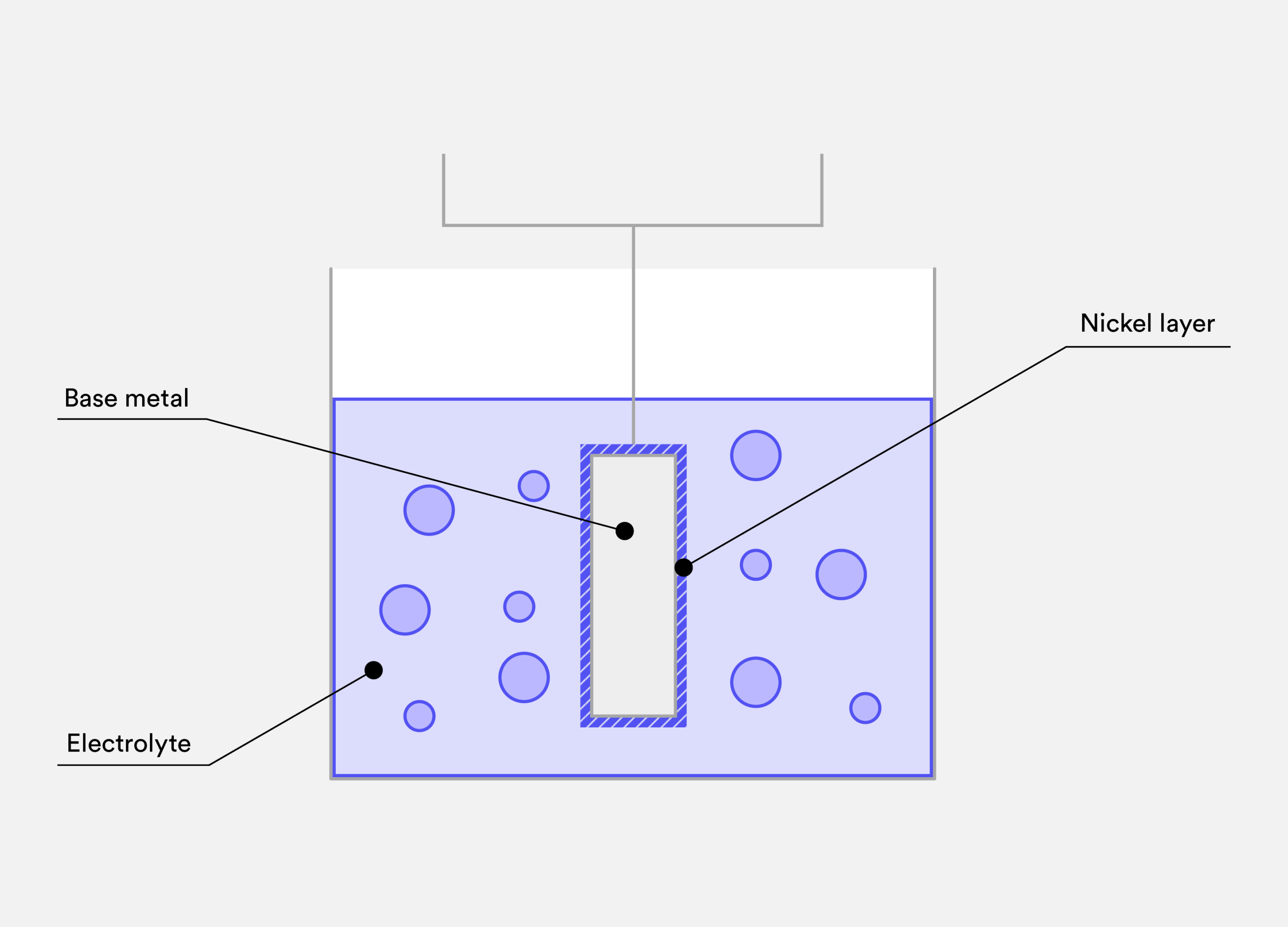

The V1 electroless nickel plating process

Electroless nickel plating provides a durable finish that resists wear, abrasion, and corrosion. Electroless nickel plating provides a durable finish that resists wear, abrasion, and corrosion. It is suitable for use with aluminium, stainless steel, and mild steel.

Electroless nickel plating provides a durable finish that resists wear, abrasion, and corrosion.

- To apply the coating, begin by washing and degreasing the parts to eliminate any contaminants, including grease and oil.

- Once the cleaning stage is complete, the substrate is treated with an acid to activate the surface and remove any oxides.

- The components are subsequently immersed in a solution of plating chemicals, where the nickel-phosphorus alloy is applied to the parts until the desired thickness is attained.

Experience the Benefits of Electroless Nickel Plating

Enhance the corrosion resistance, wear protection, and surface hardness of your metal parts with our professional electroless nickel plating services. Contact us today to discuss your project requirements and discover how our plating solutions can elevate the performance and longevity of your components.