At V1, we specialize in providing high-precision Smooth Machining services to deliver exceptional surface quality. Our state-of-the-art machining techniques and cutting-edge equipment ensure that your parts achieve a smooth finish that meets your exact specifications.

Smooth machining (Ra 1.6μm/Ra 64μin)

A finishing CNC machining operation can be applied to the part to reduce its surface roughness. The standard smoothing surface roughness is Ra 1.6 μm (64 μin). Machine marks are less evident but still visible.

| Requirement | Specification |

|---|---|

| Cosmetic availability | Non-cosmetic |

Surface Smoothness

With our Smooth Machining service, we can achieve surface roughness levels below Ra 1.6μm (64μin), ensuring a visually appealing and flawless surface. Our skilled technicians meticulously work to reduce machine marks and imperfections, resulting in a refined and polished appearance.

Benefits of Smooth Machining

- Enhanced Aesthetics: Our Smooth Machining process significantly improves the overall appearance of your parts by minimizing surface roughness and eliminating visible machining marks. This creates a professional and refined look that enhances the visual appeal of your products.

- Improved Functionality: Smooth Machining not only enhances aesthetics but also improves the functional performance of your parts. By reducing surface roughness, we ensure optimal fit, reduced friction, and enhanced durability, leading to improved overall functionality.

Customization Options

We understand that each project has unique requirements. Therefore, we offer customization options for our Smooth Machining service. If you require an even higher level of precision, we can achieve a surface roughness as low as Ra 0.8μm (32μin) upon request. Our team is dedicated to meeting your specific needs and delivering the highest quality results.

Applications of Smooth Machining

Smooth Machining has a wide range of applications across various industries, including precision instruments, optical components, and assembly parts. By utilizing our Smooth Machining service, you can ensure that your parts meet the stringent requirements of these industries, elevating the quality and performance of your products.

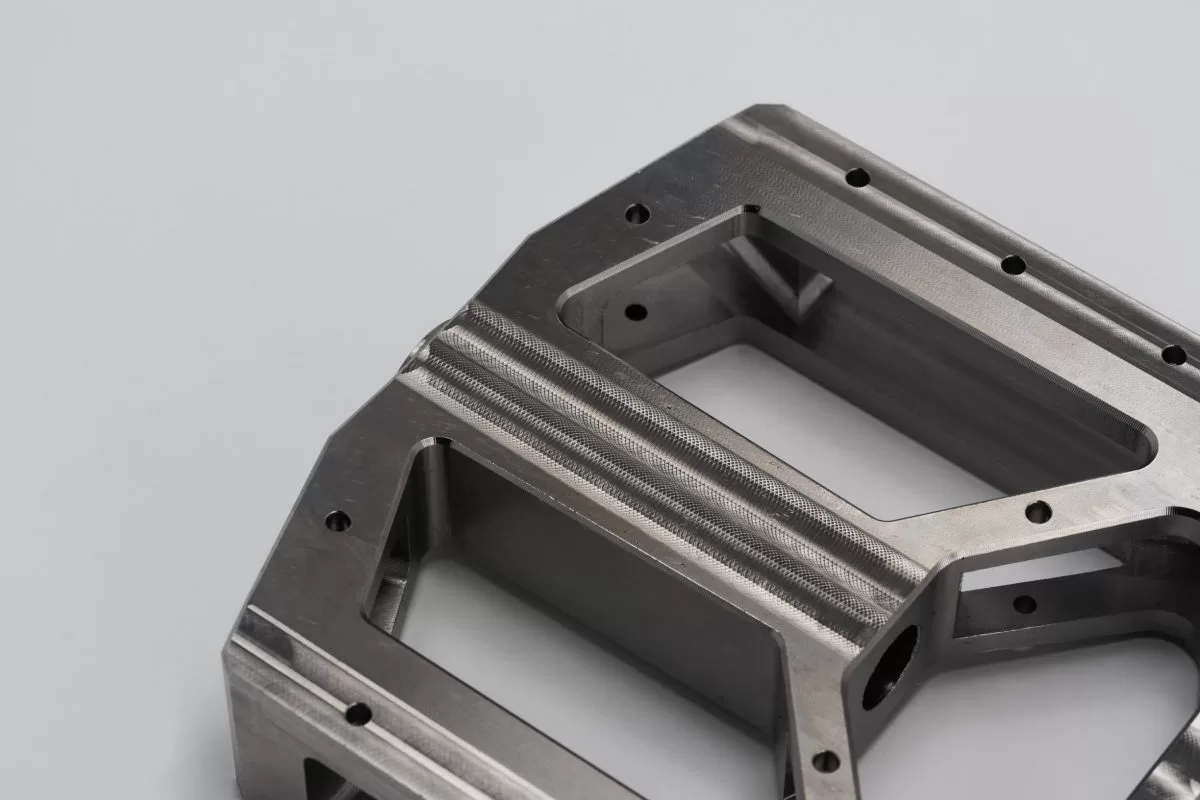

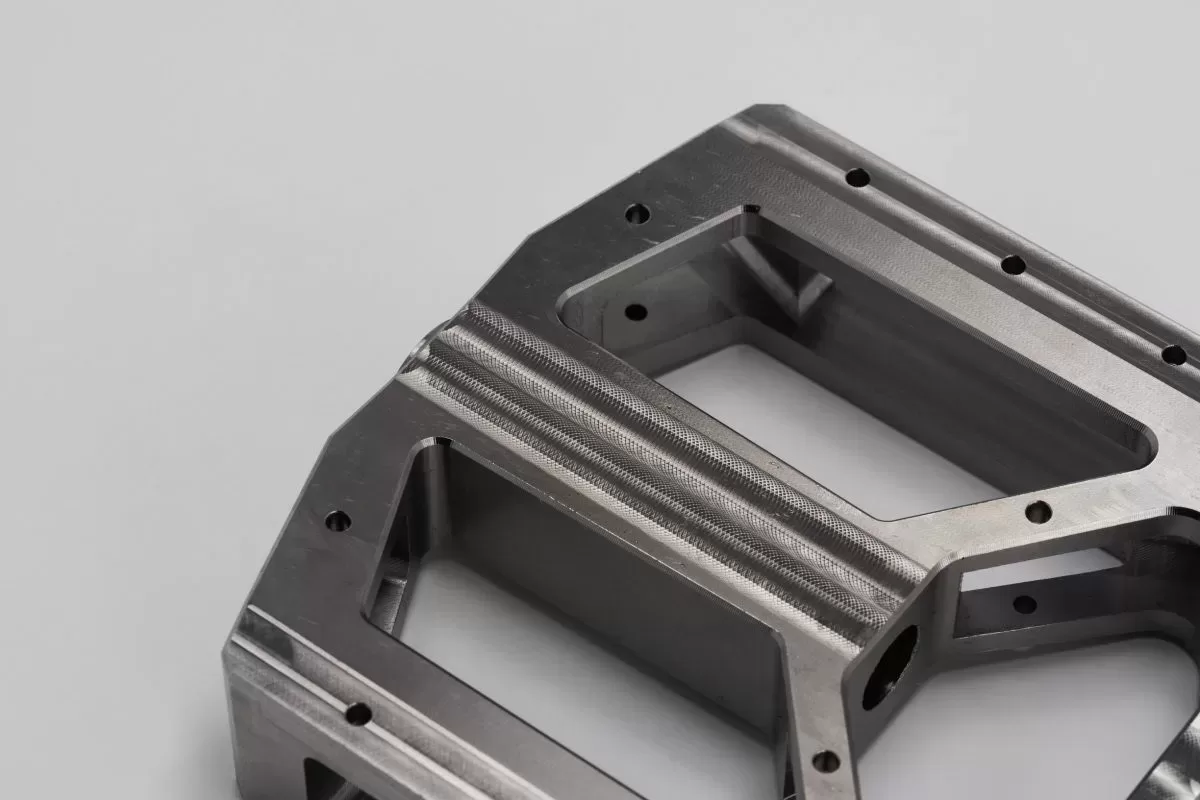

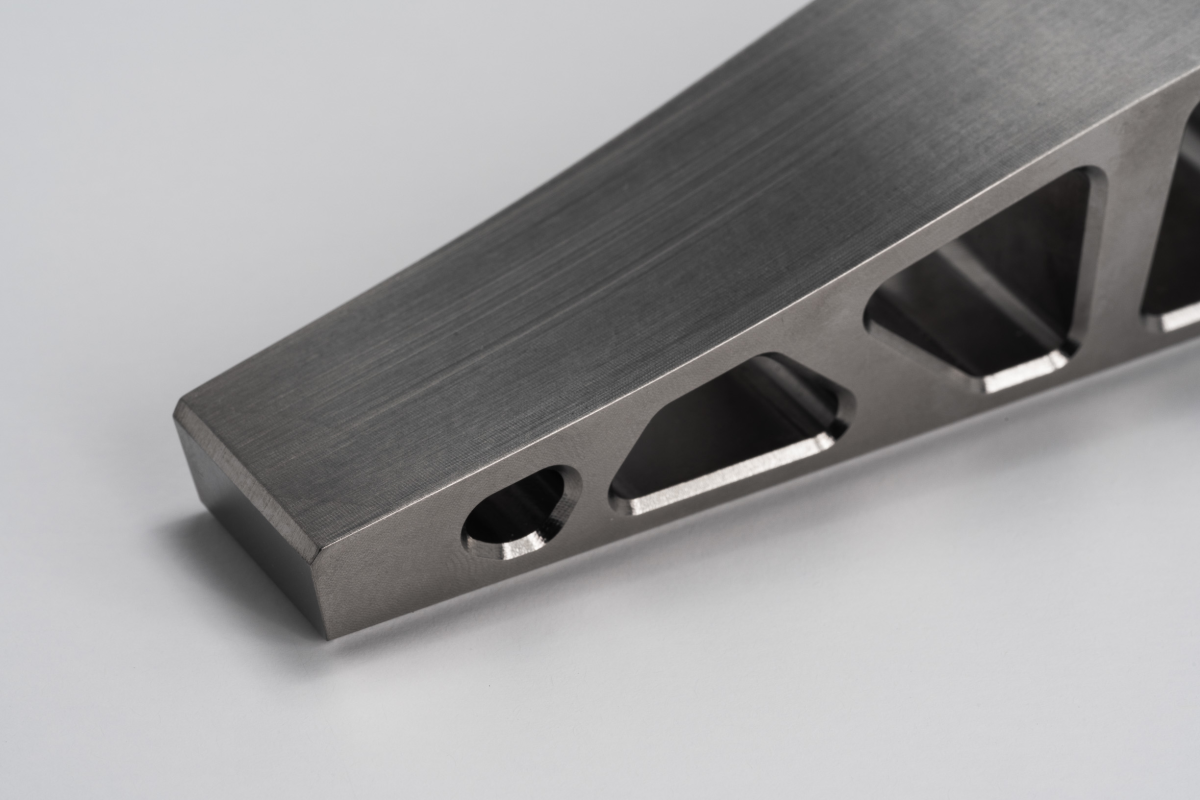

Example of a smooth machined part

Quality Assurance

We are committed to delivering exceptional results and exceeding your expectations. Our experienced team of engineers and technicians undergoes rigorous quality control measures throughout the Smooth Machining process to ensure the highest level of precision and quality. Your satisfaction is our top priority.

Contact us today to discuss your project requirements and explore how our Smooth Machining service can add value to your manufacturing process. Experience the superior surface quality and precision that sets us apart from the rest.

Smooth Machining Service Options

| Service Features | Benefits |

|---|---|

| Achieve Ra 1.6μm (64μin) surface roughness | Enhanced visual appearance |

| Reduction of machine marks and imperfections | Improved functionality |

| Customization for even finer surface finishes | Broad range of applications |

| Quality control measures at every stage | Commitment to customer satisfaction |

Experience the difference with our Smooth Machining Service. Achieve exceptional surface quality and precise finishes with surface roughness levels below Ra 1.6μm (64μin). Our skilled technicians reduce machine marks and imperfections, enhancing both aesthetics and functionality. Customization options are available for even finer finishes. With applications in various industries, our commitment to quality ensures superior results. Contact us to elevate your parts to a new level of excellence.