Vapor smoothing, also known as vapor polishing, is a post-processing technique used to improve the surface quality and appearance of 3D printed parts. It involves exposing the printed object to a solvent vapor or chemical agent that selectively melts and fuses the outer layer of the print, resulting in a smooth and glossy finish.

Vapor smoothing is particularly effective for parts printed with materials like ABS, as the solvent selectively melts the ABS plastic, blending the layers together. However, the process may not work as well with other materials, such as PLA, which may require alternative smoothing techniques.

It's important to note that vapor smoothing should be done with caution, as it involves working with chemicals and requires proper ventilation and safety measures. It is recommended to follow manufacturer guidelines and take necessary precautions when using solvents or chemical agents for vapor smoothing.

Our Vapor Smoothing Services offer a reliable solution for achieving smooth and polished surfaces on 3D printed parts. Through a specialized vapor smoothing process, we can transform the rough and layered appearance of 3D printed objects into a high-quality, finished product.

Types of vapor smoothing

| Process | Surface Preparation | Color | Applicable materials | Cosmetic availabilty | Visual appearance |

|---|---|---|---|---|---|

| MJF | As printed | Grey (default), Dyed Black | HP PA 12 | No | Smooth glossy appearance |

| SLS | As printed | White (default), Dyed Black | PA 12 | No | Smooth glossy appearance |

Why Choose Our Vapor Smoothing Services?

- Surface Quality Enhancement: Vapor smoothing is an effective method for improving the surface quality of 3D printed parts. It reduces the visible layer lines and creates a smooth, glossy finish that enhances the overall appearance of the object.

- Seamless Finish: The vapor smoothing process melts the outer layer of the 3D printed part, resulting in a seamless and uniform surface. This eliminates the distinct boundaries between individual layers, giving the object a polished and professional look.

- Time and Cost Efficiency: Vapor smoothing offers a time and cost-efficient solution compared to traditional post-processing methods. It can achieve smooth finishes on complex geometries and intricate designs without the need for extensive manual labor or additional finishing techniques.

- Versatility: Our vapor smoothing services are compatible with various 3D printing materials, including ABS, PLA, nylon, and more. Whether you require smoothing for functional prototypes, artistic models, or consumer products, we can accommodate your specific material requirements.

- Surface Preparation: Prior to vapor smoothing, proper surface preparation is carried out to ensure optimal results. This may involve cleaning, sanding, or other pre-treatment steps to remove support structures, excess material, or imperfections.

- Customization Options: We offer customization options for vapor smoothing services, allowing you to choose the desired level of smoothness and glossiness for your 3D printed parts. Our experienced team can work closely with you to achieve the desired aesthetic and functional outcomes.

- Application Compatibility: Vapor smoothing is suitable for various applications, including product prototyping, engineering parts, consumer goods, and decorative objects. It enhances the visual appeal and functionality of 3D printed components.

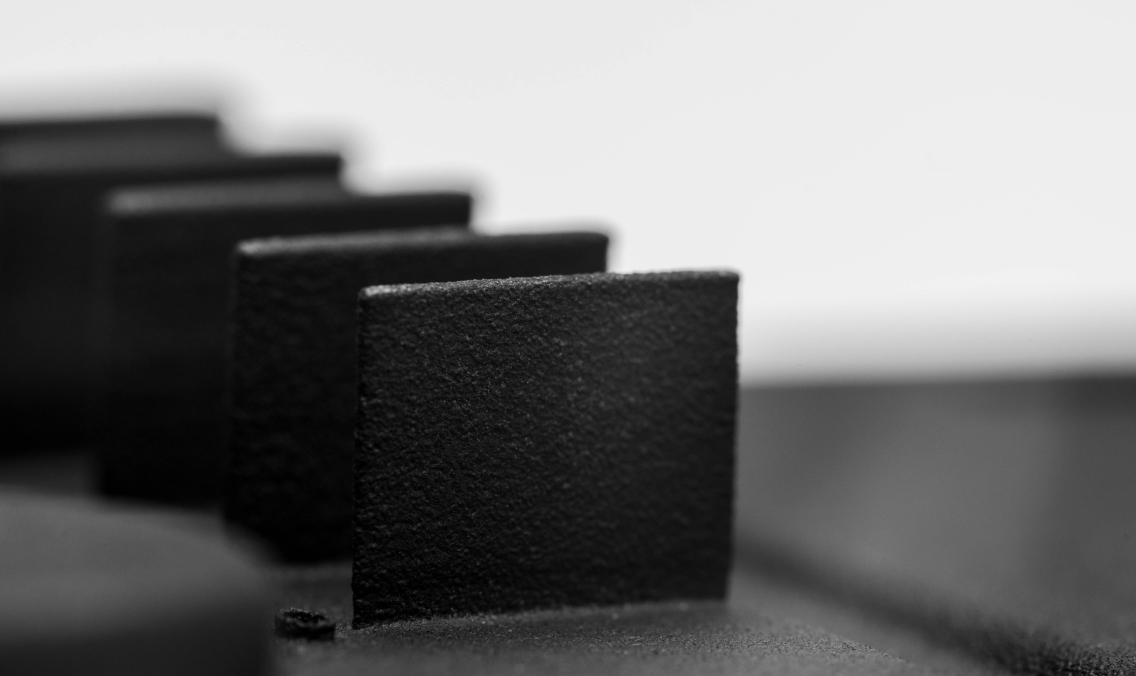

Example of a vapor smoothed dyed black part

Design considerations for vapor smoothing

When considering vapor smoothing for your 3D printed parts, there are several design considerations that can help you achieve the best results. Here are some important factors to keep in mind:

- Material Selection: Not all 3D printing materials are suitable for vapor smoothing. Typically, materials like ABS, PLA, nylon, and certain resin-based materials work well with vapor smoothing. Ensure that the material you choose is compatible with the vapor smoothing process to achieve the desired results.

- Wall Thickness: Thicker walls tend to yield better results with vapor smoothing. Thin walls may not retain the same level of detail after the smoothing process, and they can become too fragile or distorted. Aim for a minimum wall thickness that can withstand the smoothing process without compromising the structural integrity of the part.

- Surface Details and Features: Consider the surface details and features of your design. Vapor smoothing can soften or blur fine details, intricate patterns, or small text. It is best suited for parts with relatively smooth surfaces and minimal intricate details. If your design includes critical details, you may need to revise or simplify them to ensure they are not lost during the smoothing process.

- Support Structures: If your 3D printed part requires support structures, ensure that they are designed to be easily removable and do not leave behind any residue or marks. Support structures can interfere with the smoothing process and may require additional post-processing to achieve a smooth finish.

- Pre-Smoothing Preparation: Proper surface preparation before vapor smoothing is crucial. This may involve cleaning the part to remove dust, debris, or any residual printing material. Sanding the surface lightly can also help to improve the overall smoothness and adhesion of the vapor-smoothed layer.

- Post-Smoothing Considerations: After vapor smoothing, it may be necessary to perform additional finishing steps, such as sanding or polishing, to achieve the desired level of smoothness and surface quality. Consider the post-smoothing steps as part of your overall design process.

- Testing and Iteration: It is advisable to test the vapor smoothing process on a sample or prototype before applying it to your final design. This allows you to evaluate the results and make any necessary adjustments or refinements to ensure the desired outcome.

By considering these design considerations, you can optimize your 3D printed parts for vapor smoothing and achieve smooth, polished surfaces that enhance the overall quality and aesthetics of your objects.

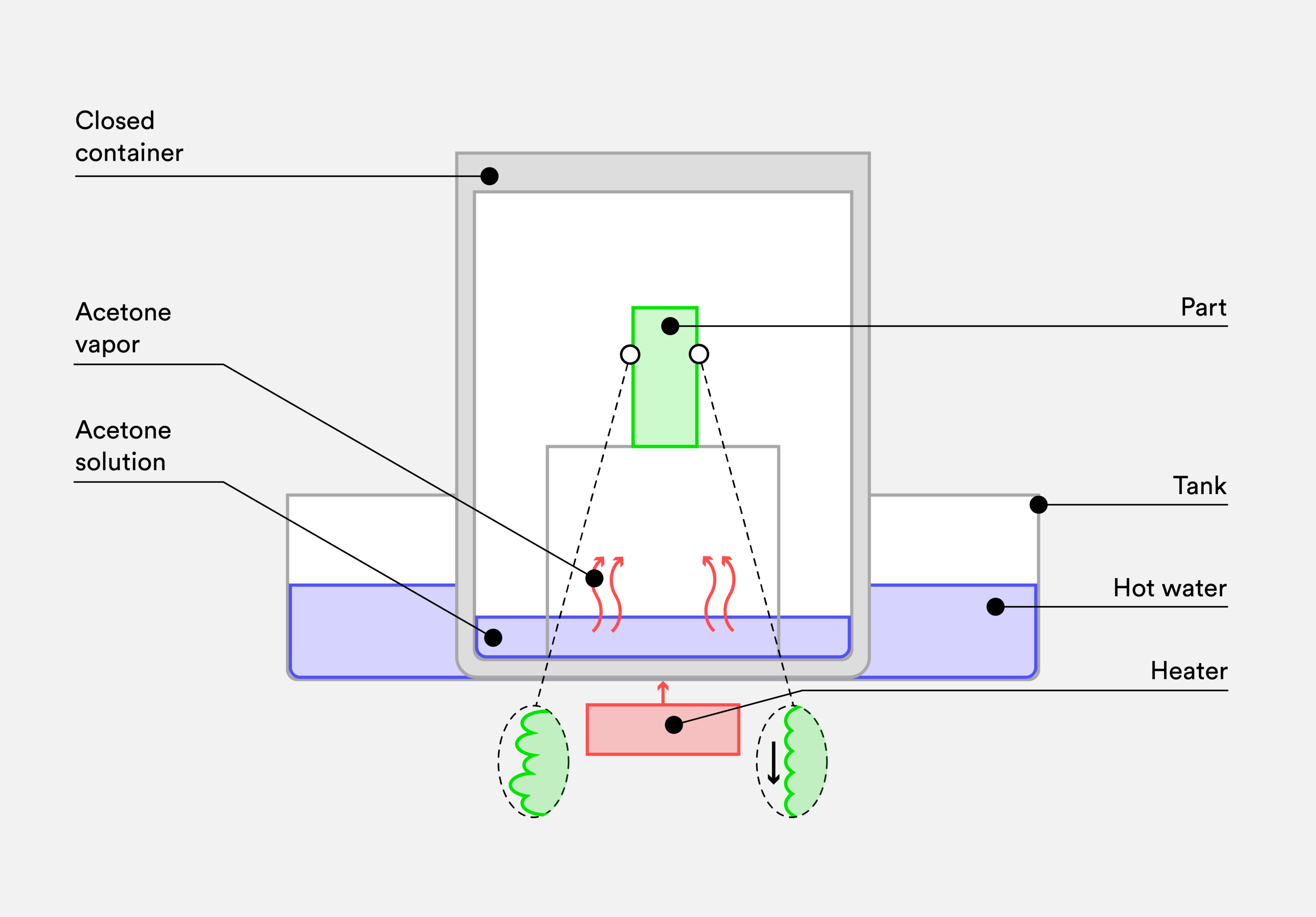

The vapor smoothing process

- After 3D printing, the part is cleaned and prepared for vapor smoothing by removing any debris.

- The part is then sealed in a container with a small amount of solvent, such as acetone or MEK (methyl ethyl ketone).

- The vapor condenses onto the surface of the part, melting and fusing the outer layer of the printed object.

- After the desired finish is achieved, the part is removed from the container and allowed to cool and dry.

Experience the Benefits of Vapor Smoothing

Transform the rough surface of your 3D printed parts into smooth and polished finishes with our professional vapor smoothing services. Contact us today to discuss your project requirements and discover how our specialized process can elevate the quality and aesthetics of your 3D printed objects.

FAQS

Which materials can undergo vapor smoothing?

Nylon 12, also known as PA 12, is a strong thermoplastic commonly used for prototypes and products. It is compatible with vapor smoothing, but intricate geometrical designs in a part may affect its effectiveness.

Can you smooth PLA or ABS using vapour?

We only currently offer vapour smoothing for MJF and SLS 3D printing (using PA 12). However, you can discuss bespoke requests and other suggestions with our team via 3dprinting@v-1.com.

Should you vapor smooth your 3D printed parts?

The process smooths out a part's surface, minimizing imperfections without altering the material composition. The answer lies in the parts' intended use. It also enhances a part's resistance to liquids.

How can you make 3D printed parts smoother?

Vapor smoothing and vibro polishing are two effective ways to reduce layer lines and texture caused during 3D printing. Alternatively, you can request vibro polishing to smooth your 3D printed parts by contacting 3dprinting@v-1.com.

How long does steam polishing a part take?

Different factors influence the time it takes to steam polish a part but typically it is finished in just a few hours.