Metal 3D Printing Service

Get quality metal 3D-printed prototypes and production parts. Request an online quote today.

- Certifications: ISO 9001:2015 | AS9100D | ITAR Registered

Service

Get metal parts in 7 days - Industrial-grade 3D printing with the DMLS process

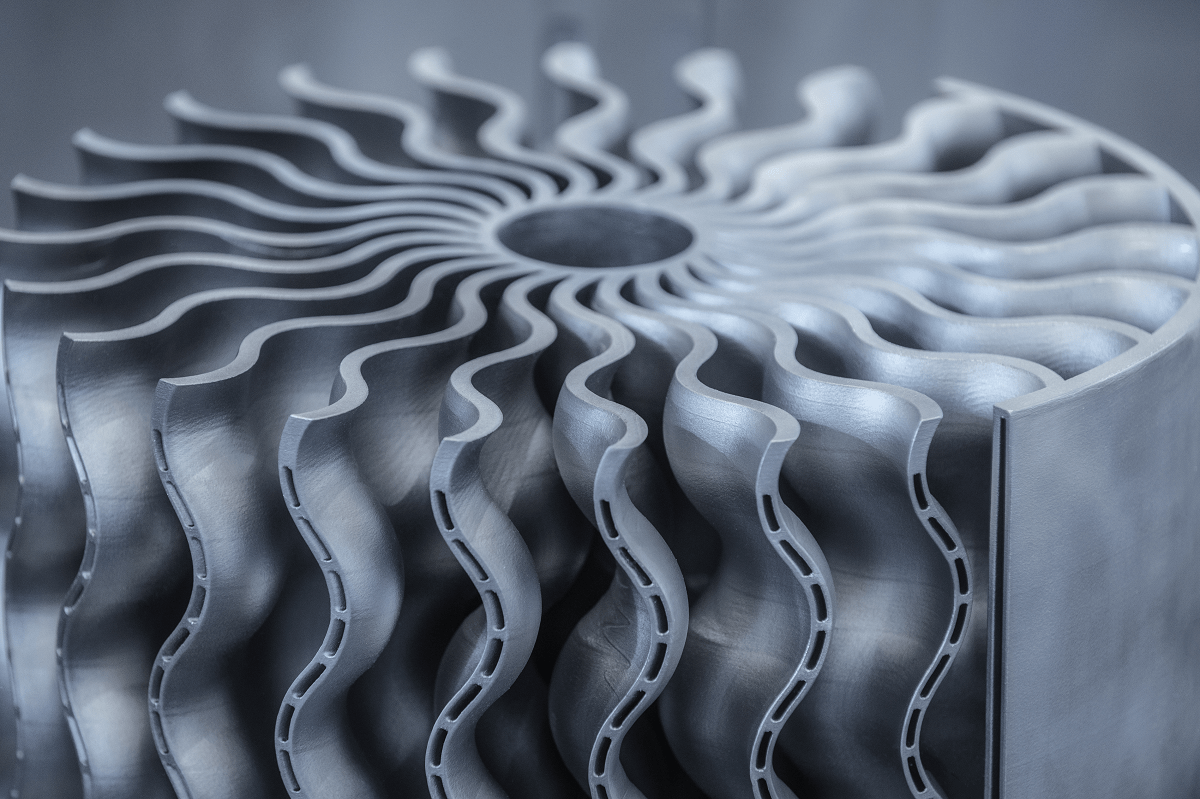

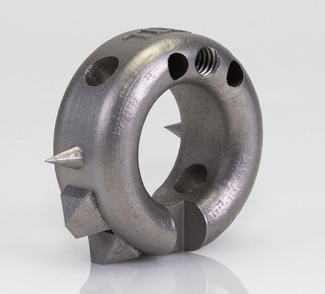

Direct Metal Laser Sintering (DMLS) is an advanced metal 3D printing process used for rapid prototyping and production of fully functional metal parts. With DMLS, it is possible to create metal prototypes and produce final parts in less than 7 days. This technology supports a wide range of metals, allowing for the production of parts suitable for end-use applications. DMLS is commonly used to prototype with production-grade materials, manufacture complex geometric shapes, produce functional end parts, and reduce the number of metal components in assemblies.

Metal 3D Printing Capabilities

Our basic metal 3D printing guidelines include key design considerations to improve part manufacturability, enhance cosmetic appearance and reduce overall production time.

| V1 | Metric | |

|---|---|---|

| Normal Resolution | 9.6 in. x 9.6 in. x 13.0 in. | 245mm x 245mm x 330mm |

| Normal Resolution (X Line*) | 31.5 in. x 15.7 in. x 19.7 in. | 400mm x 800mm x 500mm |

| High Resolution | 3.5 in. x 3.5 in. x 2.7 in. **Al and Cu:** 3.8 in. x 3.8 in. x 3.7 in. | 88mm x 88mm x 70mm **Al and Cu:** 98mm x 98mm x 94mm |

| V1 | Metric | |

|---|---|---|

| Normal Resolution | 0.0012 in. | 30 microns |

| Normal Resolution (X Line*) | Inconel: 0.00236 in. Aluminum: 0.00157 in. | Inconel: 60 microns Aluminum: 40 microns |

| High Resolution | 0.00079 in. | 20 microns |

| V1 | Metric | |

|---|---|---|

| Normal Resolution | 0.015 in. (0.030 in. for Aluminum) | 0.381mm (0.762mm for Aluminum) |

| Normal Resolution (X Line*) | 0.015 in. | 0.381mm |

| High Resolution | 0.006 in. Aluminum: 0.015 in. | 0.153mm Aluminum: 0.381mm |

Metal 3D Printing Tolerances

For well designed parts, tolerances of +0.003 inches (0.076 mm) plus 0.1% of nominal length can typically be achieved. Note that tolerances can vary depending on part geometry.

*At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine

Metal 3D Printing Material Options

Listed below are our available metal alloys for 3D printing. Different heat treatments are available depending on the material.

Stainless Steel 17-4 PH is a precipitation hardened stainless steel that is known for its hardness and corrosion resistance. If needing a stainless steel option, select 17-4 PH for its significantly higher tensile strength and yield strength, but recognize that it has far less elongation at break than 316L. Final parts built 17-4 PH receive vacuum solution heat treatment as well as H900 aging.

Primary Benefits

- Heat treated for full hardness and strength

- Corrosion resistance

Stainless steel 316L is a workhorse material used for manufacturing acid and corrosion resistant parts. Select 316L when stainless steel flexibility is needed; 316L is a more malleable material compared to 17-4 PH. Final parts built in 316L receive stress relief application.

Primary Benefits

- Acid and corrosion resistance

- High ductility

Aluminum (AlSi10Mg) is comparable to a 3000 series alloy that is used in casting and die casting processes. It has good strength -to-weight ratio, high temperature and corrosion resistance, and good fatigue, creep and rupture strength. AlSi10Mg also exhibits thermal and electrical conductivity properties. Final parts built in AlSi10Mg receive stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- Thermal and electrical conductivity

Inconel is a high strength, corrosion resistant nickel chromium superalloy ideal for parts that will experience extreme temperatures and mechanical loading. Final parts built in Inconel 718 receive stress relief application. Solution and aging per AMS 5663 is also available to increase tensile strength and hardness.

Primary Benefits

- Oxidation and corrosion resistance

- High performance tensile, fatigue, creep, and rupture strength

Cobalt Chrome (Co28Cr6Mo) is a superalloy is known for its high strength-to-weight ratio.

Primary Benefits

- High performance tensile and creep

- Corrosion resistance

Titanium (Ti6Al4V) is a workhorse alloy. Versus Ti grade 23 annealed, the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength, elongation, and hardness. Final parts built in Ti6Al4V receive vacuum stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- High temperature and corrosion resistance

Compare Material Properties

20 μm = high resolution (HR)

30, 40, and 60 μm = normal resolution (NR)

| Materials | Resolution | Condition | Ultimate Tensile Strength (ksi) | Yield Stress (ksi) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 199 | 178 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 198 | 179 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 82 | 56 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 85 | 55 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 39 | 26 | 15 | 42 HRB |

| 30 μm | Stress Relieved | 50 | 33 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 43 | 27 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 182 | 112 | 17 | 39 HRC |

| 30 μm | As Built | 176 | 119 | 14 | 38 HRC | |

| Inconel 718 | 20 μm | Stress Relieved | 143 | 98 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 144 | 91 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 208 | 175 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 139 | 83 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 201 | 174 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 153 | 138 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 144 | 124 | 18 | 33 HRC |

| Materials | Resolution | Condition | Ultimate Tensile Strength (MPa) | Yield Stress (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 20 μm | Solution & Aged (H900) | 1,372 | 1,227 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 1,365 | 1,234 | 13 | 42 HRC | |

| Stainless Steel (316L) | 20 μm | Stress Relieved | 565 | 386 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 586 | 379 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) | 20 μm | Stress Relieved | 268 | 180 | 15 | 46 HRB |

| 30 μm | Stress Relieved | 345 | 228 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 296 | 186 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) | 20 μm | As Built | 1255 | 772 | 17 | 39 HRC |

| 30 μm | As Built | 1213 | 820 | 14 | 38 HRC | |

| Copper (CuNi2SiCr) | 20 μm | Precipitation Hardened | 496 | 434 | 23 | 87 HRB |

| Inconel 718 | 20 μm | Stress Relieved | 986 | 676 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 993 | 627 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 1434 | 1207 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 958 | 572 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 1386 | 1200 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) | 20 μm | Stress Relieved | 1055 | 951 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 993 | 855 | 18 | 33 HRC |

Surface Finish Options

Standard Finish

Expect roughness values of 200 to 400 µin Ra (0.005 to 0.010mm Ra), depending on material and resolution. Support structures are removed and layer lines are visible.

Custom Finish

We offer brushed surfaces in a range of grits and polished mirror finishes. Be sure to indicate if the custom surface finish is for functional or aesthetic purposes so we can best consult you on our custom options.

Post-processing

Post-processing options for metal 3D printed parts

Surface Finishing

Heat Treatments

Mechanical Testing

Powder Analysis & Material

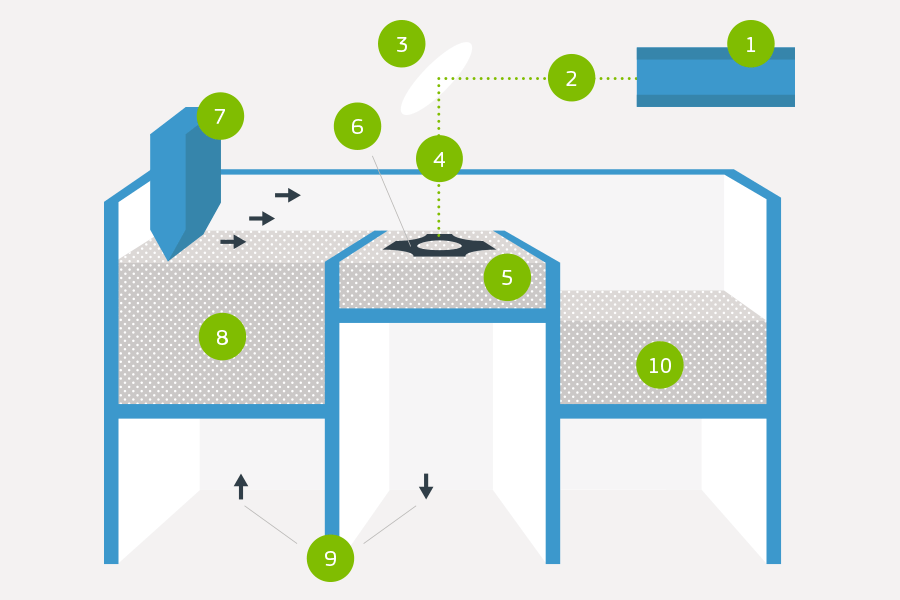

How does metal 3D printing work?

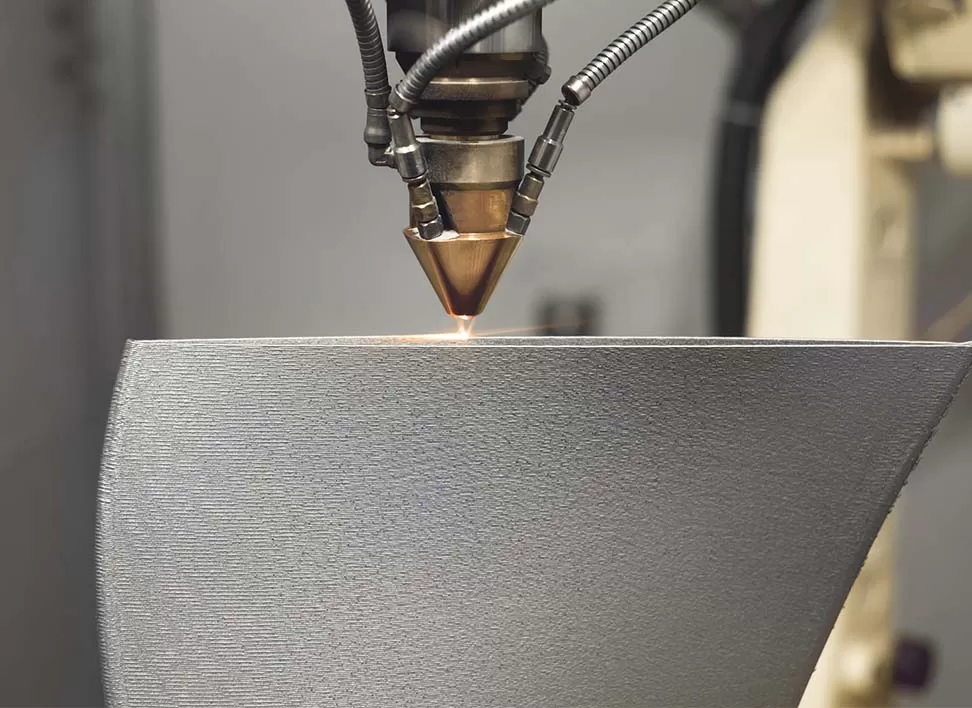

The DMLS machine begins by sintering each layer - first the support structures to the base plate, then the part itself - with a laser aimed at a bed of metallic powder. After a cross-sectional layer of powder is micro-welded, the build platform moves down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build is complete, the parts are manually brushed to remove much of the loose powder, followed by the appropriate heat treatment cycle while still mounted in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any necessary bead blasting and deburring. Final DMLS parts are close to 100 per cent dense.

Large format metal 3D printing

We have recently added the GE Additive X Line to our fleet of metal 3D printers to produce large parts in Inconel 718 and Aluminium (AlSi10Mg). Do you have a project that might be a good fit? Contact us to discuss your requirements.

Metal 3D printing for production

Improve the strength, dimensional accuracy and cosmetic quality of end-use metal parts with post-processing options such as CNC machining and heat treatment.