The Future of Post-Processing for 3D Printing

As 3D printing technology matures and expands into more applications across various industries, post-processing techniques have become an integral part of streamlining additive manufacturing workflows. Post-processing refers to various secondary procedures performed on 3D printed parts to improve their appearance, accuracy, strength and functionality. According to an industry report, the global market for 3D printing post-processing systems is predicted to reach $963 million by 2025. Several innovations in hardware and software tools promise to enhance post-processing methods for 3D printed parts in the coming years.

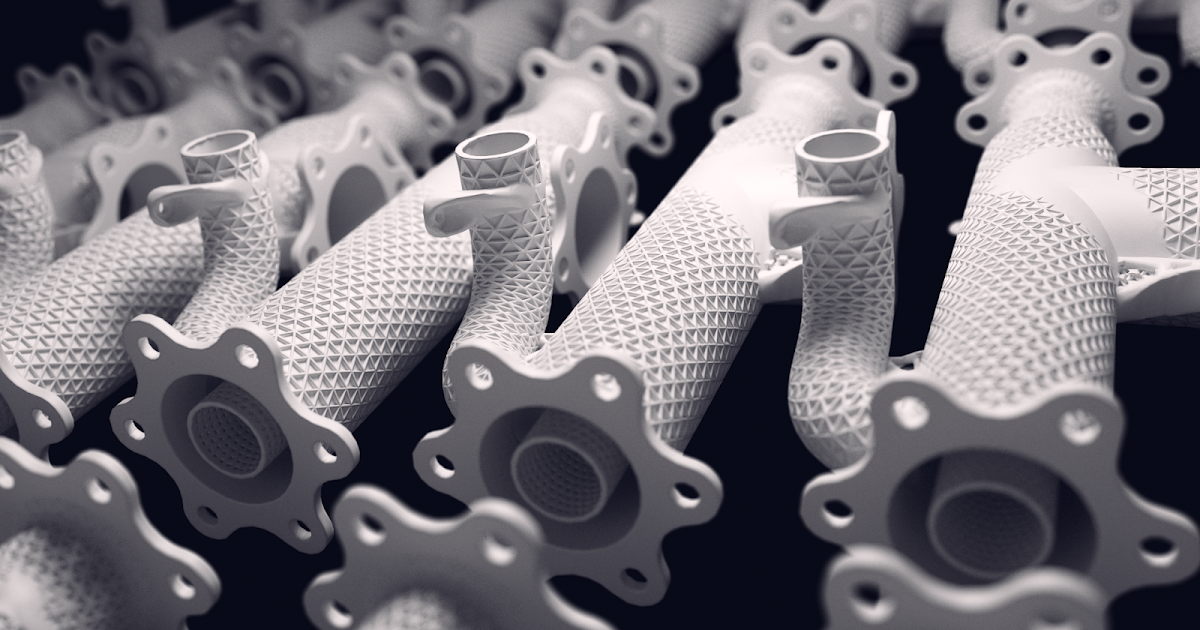

Automated Support Removal

Support structures are often required during 3D printing to anchor models that have complex geometries or overhangs. But removing these structures manually can be very labor-intensive. Many companies are now developing automated support removal solutions that use mechanical, chemical or thermal techniques to dissolve these structures much more quickly. For example, companies like AM-FLOW, PostProcess Technologies and 3YOURMIND offer automated chemical baths and spray systems tailored specifically for industrial 3D printing workflows. The global market for automated support removal systems is expected to witness robust 34.5% growth between 2022 and 2030.

Integrated Post-Processing Stations

All-in-one post-processing stations that consolidate various finishing processes into a single enclosed chamber offer a streamlined solution for additive manufacturing users. Post-processing functions like support removal, surface smoothing, UV-curing and cleaning can be built into these enclosed workstations. Companies like DyeMansion, Additive Manufacturing Technologies and 3DGence are already offering such integrated stations for polymer 3D printing which help users save time and workshop space. The global market for all-in-one post-processing technologies hit $95 million in 2021 and is forecasted to reach $303 million by 2028, exhibiting an impressive 31.5% CAGR.

Adaptive Path Planning for Finishing

The paths that post-processing tools take across 3D printed geometries have a significant impact on factors like surface quality, accuracy and cycle time. New path planning software solutions are now emerging that can intelligently analyze part topology and adapt finishing toolpaths accordingly. For example, Hybrid Manufacturing Technologies has developed AMP software that uses vision systems and AI to dynamically adapt tool motion during post-processing operations like grinding and milling. This improves overall process efficiency and design conformance. The TCT Group predicts that the global market for automated post-processing software will undergo 39% CAGR over the next decade.

Specialist Post-Processing Services

While many 3D printing service bureaus focus primarily on the actual additive manufacturing process, specialist post-processing services are now thriving as well. Companies like 3D Finishtec, AM Surface Finishing and Spectroplast exclusively offer professional post-processing services like CNC machining, mass finishing, laser polishing and EDM for 3D printed parts supplied by customers. Their expertise in post-processing techniques saves additive manufacturers and product designers considerable time and costs. Outsourcing post-processing is forecasted to capture a $2.29 billion global market share by 2030.

On-Machine Secondary Processes

New 3D printers equipped with integrated secondary processing capabilities like milling, drilling and sanding are entering the market from companies like DMG Mori, Hybrid Manufacturing Technologies and Titan Robotics. These on-machine post-processing functions eliminate additional setups and streamline many finishing steps. XYZprinting’s da Vinci Color 3D printer uses on-board inkjet technology to color 3D printed objects. The global market for industrial 3D printers with multi-tasking capabilities is predicted by an IDC report to grow at a CAGR of over 25% until 2025.

In summary, the key areas driving innovation in post-processing solutions for 3D printing involve automation, consolidation, intelligent toolpaths and secondary in-process capabilities. As additive manufacturing expands across the automotive, medical, dental, jewelry and consumer electronics sectors, more advanced post-processing systems will be vital to extracting the full value of 3D printed parts. Superior finishing quality and reduced labor costs are top motivators stimulating research in this domain.