In the realm of additive manufacturing, enhancing the mechanical properties of 3D printed parts has become a critical focus. While 3D printing offers design flexibility, improving the strength, durability, and overall performance of printed objects is often necessary. This article explores post-processing methods specifically used to enhance the mechanical properties of 3D printed parts. By employing techniques such as annealing, reinforcement, infill optimization, heat treatment, and surface coating, manufacturers can achieve superior mechanical performance in their 3D printed objects.

Annealing for Stress Relief and Increased Strength

One effective post-processing method for enhancing the mechanical properties of 3D printed parts is annealing. Annealing involves subjecting the printed part to a specific temperature and gradually cooling it, relieving internal stresses and improving the crystalline structure of the material. This process results in increased strength and toughness. A study conducted by researchers at the University of California, Berkeley, showed that annealing PLA (Polylactic Acid) printed parts increased their tensile strength by up to 30%.

Reinforcement Techniques for Enhanced Performance

Reinforcement methods, such as fiber reinforcement or insert embedding, can significantly improve the mechanical properties of 3D printed parts. Incorporating fibers like carbon fiber or glass fiber into the printing process creates composite materials that exhibit improved strength, stiffness, and impact resistance. Inserting metal or polymer inserts strategically within the printed part reinforces specific areas, increasing load-bearing capacity and overall durability.

Infill Optimization for Structural Integrity

Optimizing infill patterns, density, and orientation is another post-processing technique that enhances the mechanical properties of 3D printed parts. By adjusting the internal structure of the part, manufacturers can achieve a balance between weight reduction and structural integrity. Studies have shown that optimizing infill parameters can significantly improve the strength-to-weight ratio of 3D printed parts, making them suitable for demanding applications.

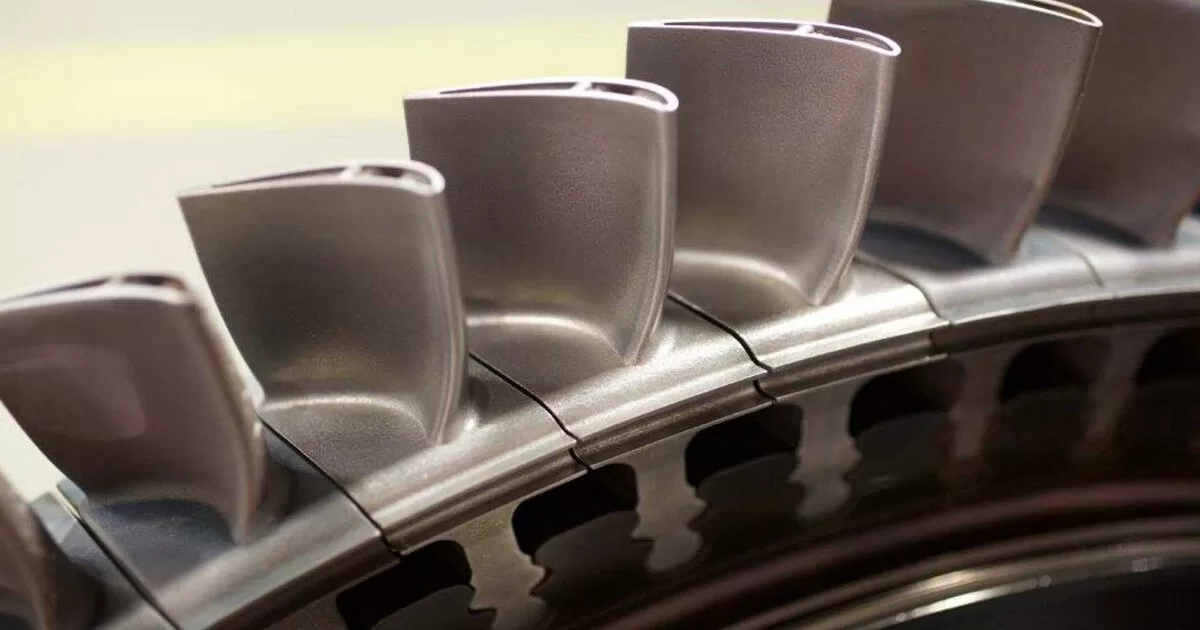

Heat Treatment for Material Transformation

Heat treatment is a post-processing method that involves subjecting the printed part to controlled heating and cooling cycles. This process can alter the material's microstructure, resulting in improved mechanical properties. Heat treatment techniques like quenching, tempering, and solution annealing enhance the hardness, toughness, and wear resistance of printed parts. Heat treatment is commonly used for metal-based 3D printed parts to achieve desired material properties.

Surface Coating for Protection and Performance

Surface coatings provide an additional layer of protection and can improve the mechanical properties of 3D printed parts. Coatings such as epoxy, polyurethane, or ceramic coatings offer enhanced toughness, chemical resistance, and surface hardness. These coatings can also provide lubricity or low-friction properties, making them suitable for applications involving sliding or moving parts.

Conclusion

Post-processing methods designed to improve the mechanical properties of 3D printed parts offer numerous possibilities for enhancing performance and durability. Techniques such as annealing, reinforcement, infill optimization, heat treatment, and surface coating address the limitations of raw 3D printed parts, enabling manufacturers to create functional and reliable components. Leveraging these methods, the additive manufacturing industry continues to push the boundaries of what is achievable in terms of mechanical performance.