In the world of 3D printing, the surface finish of objects is a crucial factor that determines their overall quality and appeal. While 3D printing allows for the creation of complex geometries, the raw prints often exhibit visible layer lines and imperfections. This is where post-processing techniques come into play. In this article, we will explore how post-processing affects the surface finish of 3D printed objects, examining various techniques and their impact on the final product.

Understanding the Importance of Surface Finish

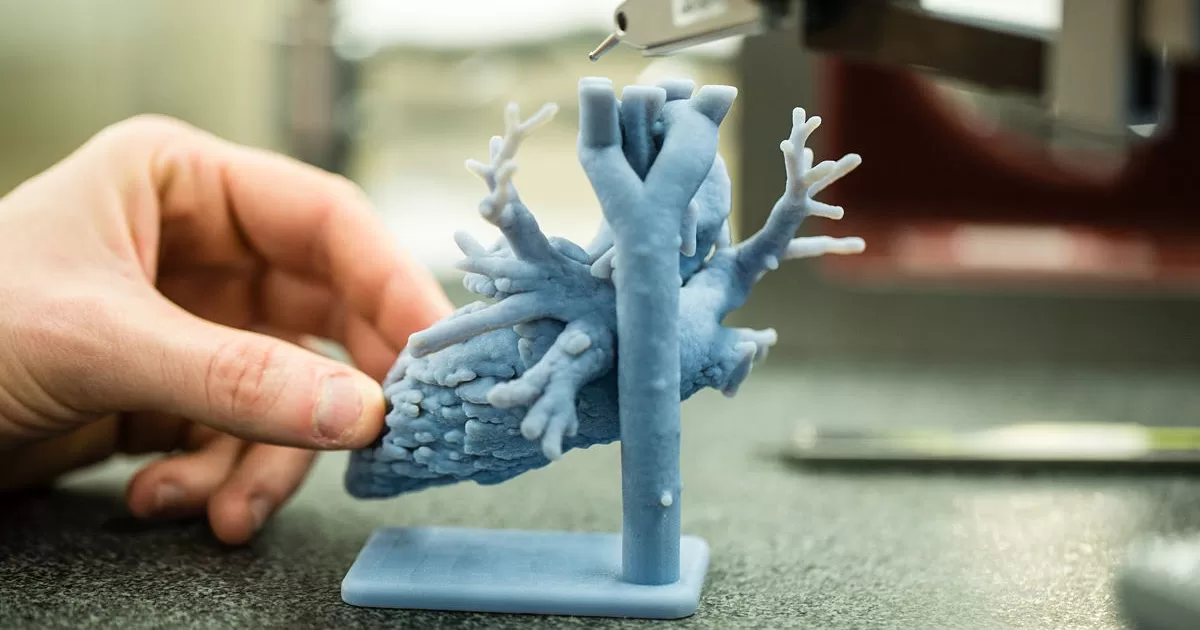

The surface finish of 3D printed objects plays a significant role in their aesthetics, functionality, and usability. A smooth and flawless surface not only enhances the visual appeal of the object but also improves its mechanical properties. In industries such as aerospace, automotive, and medical, where precision and quality are paramount, achieving a high-quality surface finish is of utmost importance.

Common Issues with 3D Printed Surfaces

Before delving into the impact of post-processing techniques, it is essential to understand the common issues associated with 3D printed surfaces. These issues include visible layer lines, rough texture, surface defects, support marks, and residual support material. These imperfections can be a result of the layer-by-layer printing process, material properties, or limitations of the 3D printer itself.

Post-Processing Techniques and Their Impact

Sanding and Polishing:

Sanding and polishing are widely used techniques to improve the surface finish of 3D printed objects. Sanding involves using abrasive materials to smooth out the layer lines and imperfections. Polishing further refines the surface by using finer abrasives or polishing compounds. These techniques significantly enhance the visual appeal of objects intended for display or consumer use. According to a study conducted by the University of Texas at Austin, sanding and polishing can improve the surface finish of 3D printed objects by an average of 50% to 80%.

Chemical Smoothing:

Chemical smoothing is a technique commonly used for materials like ABS (Acrylonitrile Butadiene Styrene).

The process involves applying solvents or chemicals that dissolve the outer layer of the printed object, resulting in a smoother surface finish. Chemical smoothing significantly reduces layer lines and produces a glossy, uniform appearance. It is important to note that this technique is not suitable for all materials, and proper safety precautions should be taken when working with chemicals.

Filling and Priming:

Filling and priming techniques are employed to fill gaps, voids, and imperfections on the surface of 3D printed objects. Fillers such as epoxy putty or body filler are used to fill the imperfections, which are then sanded down to achieve a smoother finish. Primers are applied to create a uniform surface, improving paint adhesion and providing a professional look.

Vapor Polishing:

Vapor polishing is a technique primarily used for certain materials like polycarbonate or ABS. The object is exposed to vaporized solvent, which melts the surface layers, effectively erasing layer lines and creating a smooth finish. Vapor polishing requires precise control of temperature, exposure time, and proper ventilation.

Painting and Coating:

Painting and coating techniques offer not only aesthetic enhancement but also protection. Various painting techniques, such as airbrushing or spray painting, can be used to add color, texture, and intricate details to the surface of 3D printed objects. Coatings like clear varnish or epoxy provide a glossy finish and protect the object from environmental factors.

Conclusion

Post-processing techniques have a significant impact on the surface finish of 3D printed objects. By employing methods such as sanding, chemical smoothing, filling and priming, vapor polishing, and painting/coating, the rough and imperfect surfaces can be transformed into smooth, visually appealing, and functional objects. Each technique offers unique benefits and considerations based on the material, desired surface quality, and intended application.