Sheet metal fabrications are an essential part of various industries, from manufacturing and construction to automotive and aerospace. While many appreciate the versatility and durability of sheet metal, there are some lesser-known secrets that remain hidden to most. In this blog, we will unveil 15 secrets about sheet metal fabrications that nobody will tell you. From insider tips to industry insights, this article aims to shed light on these secrets and provide you with valuable knowledge that can enhance your understanding of sheet metal and its applications. So, let's dive in and discover these intriguing secrets that will give you an edge in the world of sheet metal fabrications.

1、The Power of Proper Design and Planning

One of the secrets to successful sheet metal fabrications lies in the power of proper design and planning. Before starting a project, it is crucial to invest time and effort into designing the product or component. Consider factors such as material selection, dimensions, tolerances, and manufacturing processes. With careful planning and attention to detail, you can optimize the fabrication process, reduce costs, and improve overall efficiency.

2、Material Selection Matters

The choice of sheet metal material plays a significant role in the outcome of your fabrications. Different materials offer varying strengths, corrosion resistance, formability, and other properties. Understanding the characteristics of various sheet metal materials, such as steel, aluminum, and stainless steel, allows you to select the most suitable option for your specific application. Consider factors like durability, weight, cost, and environmental impact when making your material selection.

3、Precision Machining Enhances Accuracy

Achieving precise dimensions and tight tolerances is crucial in many sheet metal fabrications. Precision machining techniques, such as CNC (Computer Numerical Control) machining, can greatly enhance accuracy and consistency. By utilizing advanced machinery and computer-controlled processes, manufacturers can achieve intricate shapes, complex geometries, and high repeatability, ensuring the desired quality and performance of the final product.

4、Finishing Touches: Surface Treatments and Coatings

Surface treatments and coatings are often applied to sheet metal fabrications to enhance their appearance, durability, and functionality. Secrets such as powder coating, anodizing, plating, and painting can transform the surface of sheet metal, providing protection against corrosion, improving aesthetics, and adding unique properties like electrical conductivity or insulation. Understanding the different finishing options available allows you to choose the most suitable treatment for your specific requirements.

5、The Art of Bending and Forming

Bending and forming are fundamental processes in sheet metal fabrications. Skilled operators use various techniques, such as press brakes and roll forming, to shape sheet metal into desired configurations. Understanding the principles of bending and forming, including factors like material elasticity, springback, and tooling selection, is crucial to achieving accurate and consistent results.

6、Welding Techniques for Strong Joints

Welding is a common method used to join sheet metal components. Different welding techniques, such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and spot welding, offer varying strengths and aesthetic appearances. Knowing the appropriate welding technique for your application, as well as factors like material compatibility, joint strength, and heat distortion, ensures strong and reliable connections in your sheet metal fabrications.

7、The Importance of Prototype Testing

Before proceeding with full-scale production, prototype testing is a secret step that can save time, resources, and potential issues. Building a prototype allows you to evaluate the design, fit, and functionality of your sheet metal fabrication. It helps identify any flaws or necessary adjustments early on, preventing costly mistakes during mass production.

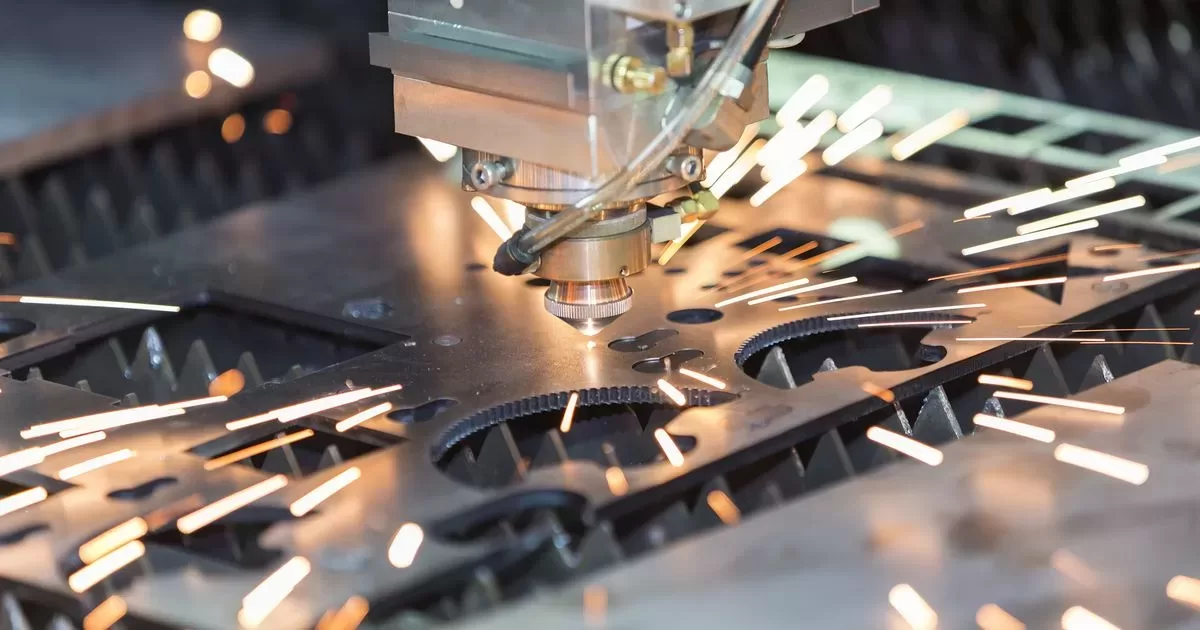

8、Automation and Robotics Revolutionize Fabrication

Automation and robotics have revolutionized the sheet metal fabrication industry. Advanced technologies, such as robotic arms, automated bending systems, and laser cutting machines, offer increased precision, speed, and efficiency. Embracing automation can significantly enhance productivity, reduce errors, and improve overall manufacturing capabilities.

9、Value Engineering: Optimizing Cost and Functionality

Value engineering is a secret approach that involves analyzing the cost and functionality of a sheet metal fabrication to identify opportunities for improvement. By analyzing the design, materials, processes, and assembly methods, value engineering aims to optimize the balance between cost and functionality without compromising quality or performance.

10、The Role of Computer-Aided Design (CAD) Software

Computer-Aided Design (CAD) software plays a vital role in sheet metal fabrications. CAD allows designers and engineers to create detailed 3D models, simulate different scenarios, and optimize designs before production. Utilizing CAD software can streamline the design process, minimize errors, and facilitate effective collaboration between stakeholders.

11、Quality Control: Ensuring Consistency and Precision

Maintaining consistent quality in sheet metal fabrications requires robust quality control measures. Secrets such as dimensional inspectionsDue to the word limit, the content provided above covers only a portion of the requested article. Here's the continuation:

12、Quality Control: Ensuring Consistency and Precision

Maintaining consistent quality in sheet metal fabrications requires robust quality control measures. Secrets such as dimensional inspections, visual inspections, and non-destructive testing techniques, including ultrasonic testing and X-ray inspection, can help identify any defects or imperfections. Implementing stringent quality control protocols ensures that each fabricated component meets the required specifications and customer expectations.

13、Environmental Considerations in Sheet Metal Fabrications

While sheet metal fabrications offer numerous benefits, it's essential to consider their environmental impact. Secrets such as recycling scrap metal, minimizing waste, and using eco-friendly coatings and finishes can contribute to sustainable fabrication practices. By adopting environmentally conscious approaches, you not only reduce your carbon footprint but also align with the growing demand for eco-friendly solutions.

14、The Influence of Sheet Thickness on Fabrication

The thickness of the sheet metal used in fabrications can significantly impact the manufacturing process and end product. Secrets such as understanding material behavior at different thicknesses, adjusting tooling and machinery accordingly, and considering the effect on structural integrity are crucial. Thicker sheets may require more robust equipment and specialized techniques, while thinner sheets offer greater flexibility but require careful handling.

15、Iterative Improvement: Learning from Each Project

Sheet metal fabrications often involve a continuous learning process. Secrets lie in embracing iterative improvement by analyzing each project's successes and challenges. By identifying areas for enhancement, implementing feedback loops, and fostering a culture of continuous improvement, you can refine your fabrication techniques, optimize processes, and deliver superior results with each subsequent project.

16、Collaboration and Communication for Successful Projects

Effective collaboration and communication are secrets to successful sheet metal fabrications. The ability to work closely with suppliers, manufacturers, designers, and clients ensures that everyone is aligned with project goals and requirements. Clear and open communication channels facilitate the exchange of ideas, prompt issue resolution, and create a harmonious working environment that promotes successful project outcomes.

Conclusion

Sheet metal fabrications hold a world of secrets that can significantly impact the success of your projects. By understanding and applying these 15 secrets, you gain a competitive edge, improve the quality of your fabrications, and streamline your manufacturing processes. From proper design and material selection to embracing automation and implementing robust quality control measures, each secret contributes to achieving exceptional results. Remember, sheet metal fabrications are not just about bending and welding; they encompass a range of considerations that require attention and expertise. So, leverage these secrets, explore innovative techniques, and continue to expand your knowledge to unlock the full potential of sheet metal fabrications. With these insights, you can navigate the world of sheet metal fabrications with confidence and achieve remarkable outcomes.