Becoming an expert in the field of injection molding requires a combination of technical knowledge, practical experience, and a commitment to continuous learning. In this article, we will explore essential tips that will empower you to master the art of injection molding. From understanding material selection to optimizing processing parameters, these insights will help you unlock your full potential and excel in the world of injection molding.

Injection molding is a versatile manufacturing process used across industries to produce high-quality plastic parts. Whether you are a beginner or have some experience in the field, these tips will provide valuable guidance to enhance your skills and expertise.

Understand Material Selection

To become an injection molding expert, it is essential to have a deep understanding of different plastic materials and their properties. Consider factors such as strength, durability, flexibility, and temperature resistance when selecting the appropriate material for your injection molding project. By choosing the right material, you can ensure the desired characteristics and performance of the final product.

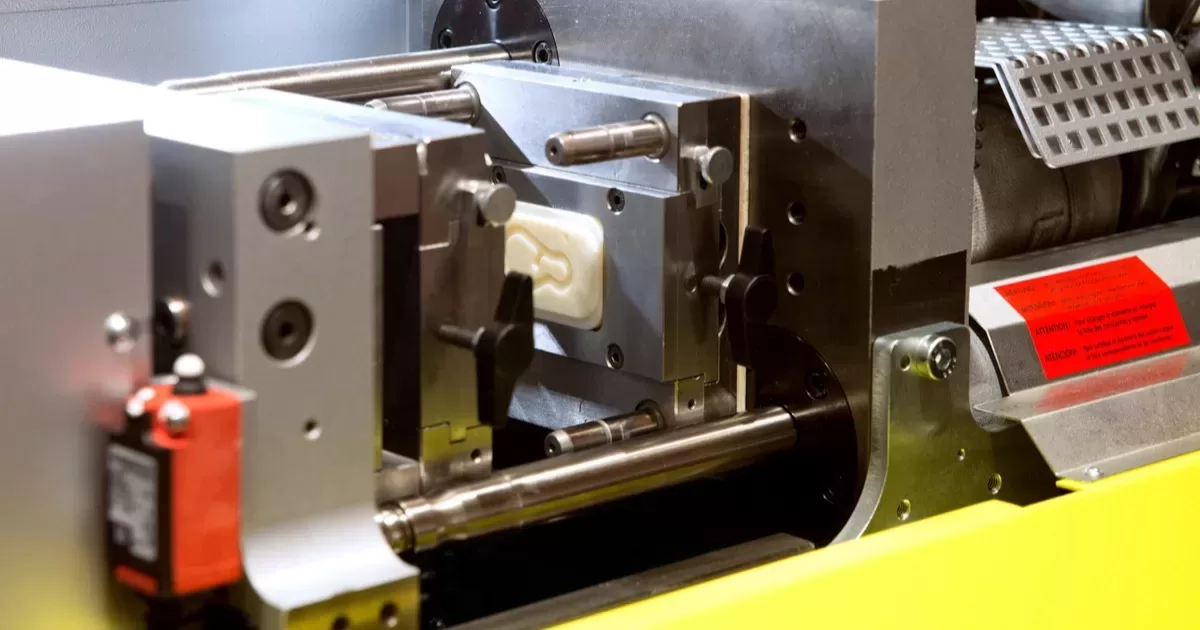

Master Mold Design

The design of the mold plays a crucial role in the success of an injection molding project. Learn the principles of mold design, including gate placement, parting line location, and cooling channel design. A well-designed mold enables efficient production, minimizes defects, and ensures the production of high-quality parts.

Optimize Processing Parameters

Optimizing processing parameters is vital for achieving consistent and high-quality results in injection molding. Continuously monitor and adjust parameters such as temperature, injection speed, and pressure to optimize the molding process. Proper parameter control ensures uniform part filling, minimizes defects, and maximizes production efficiency.

Embrace Scientific Molding

Scientific molding is an approach that utilizes data-driven analysis and optimization to achieve precise control and repeatability in the injection molding process. By implementing scientific molding techniques, you can achieve improved part quality, reduced cycle times, and enhanced overall performance.

Implement Robust Quality Control

Quality control is a critical aspect of injection molding. Develop a comprehensive quality control plan that includes regular inspection, dimensional analysis, and testing of finished parts. By implementing robust quality control measures, you can ensure that all parts meet the required specifications and customer expectations.

Stay Updated on Industry Trends

The field of injection molding is constantly evolving with new technologies, materials, and techniques. Stay updated on the latest industry trends by attending conferences, webinars, and workshops. Engage with industry experts and network with peers to stay ahead of the curve and incorporate innovative practices into your work.

Continuously Learn and Improve

To become an expert in injection molding, embrace a mindset of continuous learning and improvement. Invest in your professional development by participating in training programs and workshops. Seek feedback from experienced professionals, analyze your own work, and continuously seek opportunities to enhance your knowledge and skills.

Troubleshooting Expertise

Develop the ability to identify and troubleshoot common issues that may arise during the injection molding process. Some common problems include flash, sink marks, warpage, and short shots. Effective problem-solving skills are essential for maintaining production efficiency and ensuring high-quality output.

Collaborate with Suppliers

Forge strong relationships with material suppliers, mold makers, and equipment manufacturers. Collaborating with trusted partners can provide valuable insights, support, and access to cutting-edge technologies. By working closely with suppliers, you can optimize material selection, mold design, and overall production processes.

Emphasize Mold Maintenance

Regular maintenance of molds is crucial for ensuring optimal performance and extending their lifespan. Implement a proactive maintenance schedule that includes cleaning, lubrication, and periodic repairs. By properly maintaining the molds, you can minimize downtime, reduce defects, and ensure consistent part quality.

Conclusion

Becoming an expert in injection molding requires a combination of knowledge, experience, and continuous improvement. By understanding material selection, mastering mold design, optimizing processing parameters, embracing scientific molding, implementing robust quality control, staying updated on industry trends, continuously learning and improving, developing troubleshooting expertise, collaborating with suppliers, and emphasizing mold maintenance, you can enhance your skills and become a respected professional in the field. Keep honing your expertise, exploring new techniques, and staying abreast of the latest advancements to excel in the exciting world of injection molding.To learn more about injection molding and explore our comprehensive range of services, please visit our injection molding services page.