3D printing, also known as additive manufacturing, is transforming production processes across many industries. In the luxury sector, brands leverage 3D printing for rapid prototyping, bespoke products, jewelry casting, and innovative manufacturing. The technology enables greater complexity and customization for luxury items from cars to fashion at lower costs. As 3D printing advances, its applications in high-end goods will continue to grow.

Automotive Prototyping

Luxury and supercar brands like Ferrari, Porsche, and Koenigsegg utilize 3D printing to accelerate prototype development. Printing prototype vehicle parts in-house enables faster design iteration compared to outsourcing. The technology also reduces tooling costs. Automakers can test multiple variations of components like air vents and dashboards in the early design phase. 3D printing lets engineers evaluate technical feasibility and aesthetics without committing to full production. Shorter prototyping timelines help luxury brands reach the market faster.

Bespoke Products

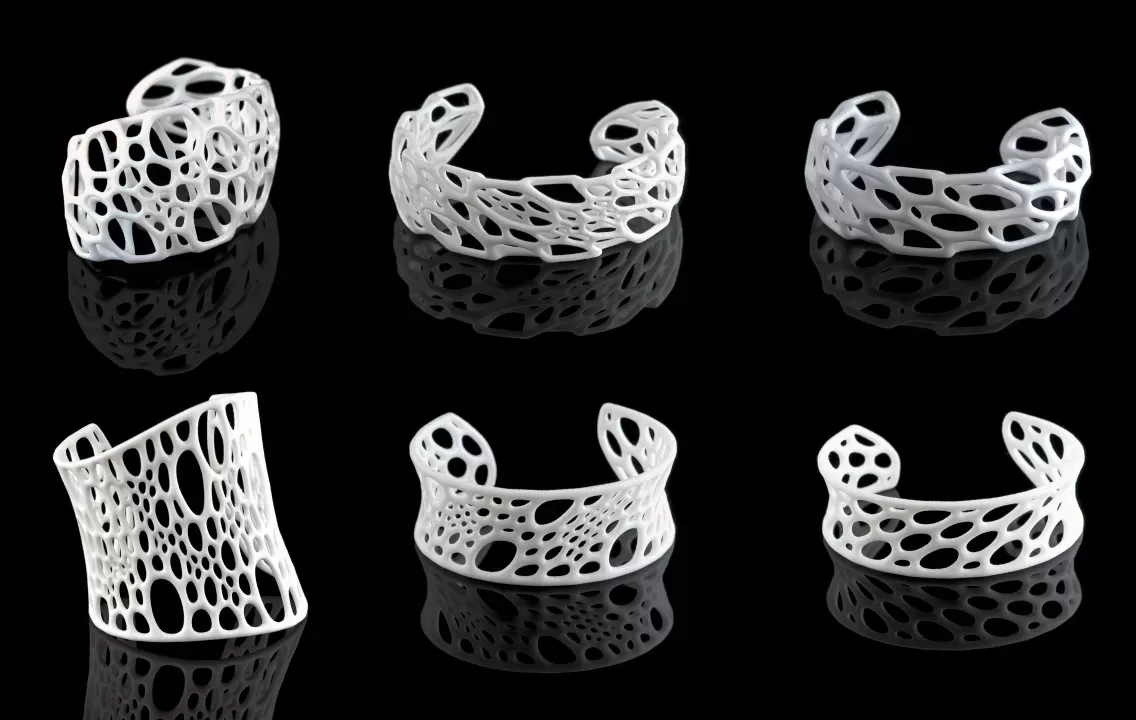

3D printing facilitates small-batch production for custom and personalized luxury goods. Companies can offer tailor-made products adapted to individual customer needs. From customized insoles and nutrition supplements to bespoke eyewear and headphones, 3D printing makes small-volume custom manufacturing economical. Jewelry brands also leverage the technology to provide made-to-order designs at lower costs and quicker turnarounds. The ability to rapidly print bespoke goods creates a new realm of exclusivity.

Jewelry Casting

Many high-end jewelry brands have adopted 3D printing for rapid casting of precious metals. The process involves 3D printing a disposable wax model of the jewelry design. This model serves as a pattern for the metal casting. 3D printing the wax prototypes enables intricate jewelry designs without the lead time and cost of machining. It also reduces waste compared to the traditional wax carving method. After casting the metal, jewelers polish and finish the jewelry into a luxury piece. The technology cuts production time from weeks to days.

Footwear Production

Some athletic and fashion footwear brands like Adidas and Under Armor utilize 3D printing for advanced shoemaking. The technology allows novel sole shapes optimized for weight and function. Midsoles can be digitally tuned to provide custom cushioning and support. Additive manufacturing also decreases waste from the subtractive molding process. For limited editions and concept shoes, 3D printing enables rapid prototyping. As the technology matures, 3D printed footwear is projected to gain broader traction.

Innovative Manufacturing

Luxury brands leverage 3D printing’s design freedom to create products using new techniques and materials. Concept cars and yachts employ large-scale 3D printing with metals and composites for sleeker, lightweight designs. Fashion brands combine 3D printing with new materials such as recycled plastics and sustainable biofabrics. High-performance cycling equipment and other sports gear also utilize additive manufacturing. The ability to manufacture complex and novel geometries expands the realm of luxury design.

As 3D printing technology advances, its applications in luxury goods will proliferate. The benefits of rapid prototyping, bespoke production, and innovative manufacturing make it an essential tool for creating exclusive products. 3D printing enables luxury brands to provide customers greater personalization along with faster product development. The technology will open new avenues for customization, limited editions, and manufacturing innovation in the luxury industry.