The automotive industry has been an early adopter of 3D printing technology. Also known as additive manufacturing, 3D printing builds objects layer-by-layer from digital models. It offers car manufacturers greater design freedom, faster prototyping, tooling flexibility, and supply chain efficiencies. As the technology advances, 3D printing is poised to transform automotive design, manufacturing, and customization.

Prototyping

One of the biggest advantages of 3D printing is accelerating the prototyping process. Automakers use it to quickly iterate designs and test form, fit, and functionality. Parts printed in plastic allow engineers to evaluate assembly integration, ergonomics, aesthetics, and more. Traditional prototype tooling like CNC machining or injection molding can take weeks or months. With 3D printing, automakers can test design concepts in days or even hours. Quicker prototyping speeds up development time, reducing costs. It also enables automakers to bring vehicles to market faster.

Tooling

Automakers leverage 3D printing to make custom tools like jigs, fixtures, and assembly aids for factory floors. 3D printed tooling is ideal for short runs or bridge manufacturing until higher volume production tooling is ready. Tools with complex geometries are easier to print than machine. Lightweight 3D printed tools also reduce strain on production workers. Ford used 3D printing to create a flexible, modular tool system that can be easily reconfigured to build various vehicles on the same line. The ability to print custom tools on demand boosts manufacturing flexibility.

End-Use Parts

While use of 3D printed parts in vehicle production is still limited, more manufacturers are adopting the technology. Lightweight non-critical parts like brackets, housings, and interiors are printed using plastics and metal alloys. The BMW i8 has over 10 3D printed components, including air ducts and housing for the rear lights. Automakers are also assessing the technology for higher volume engine and structural components. 3D printing provides benefits for complex geometries and lightweight optimization that are unfeasible with conventional methods. Vehicle weight reduction through 3D printed parts can improve fuel economy.

Mass Customization

3D printing enables automakers to offer new levels of customization without high costs. Drivers can get bespoke interiors to suit individual tastes. Exterior customization such as personalized badges or graphics are possible. For supercars, manufacturers utilize 3D printing for buyers to tailor components like air vents and steering wheels. The ability to produce low volumes of customized parts on demand makes personalization cost effective. As the technology matures, mass customization will become more prevalent across vehicle segments.

Spare and Replacement Parts

When spare parts for older or rare vehicles are hard to source, 3D printing offers a solution. Some specialty auto shops are adopting the technology to create replacements for scarce components. With 3D scanning, existing parts can be digitized to 3D print replicas. This helps repair and restore classic cars where finding certain parts may be impossible otherwise. 3D printing also facilitates on-demand manufacturing of low-quantity spares. Lead times of weeks can be cut down to days.

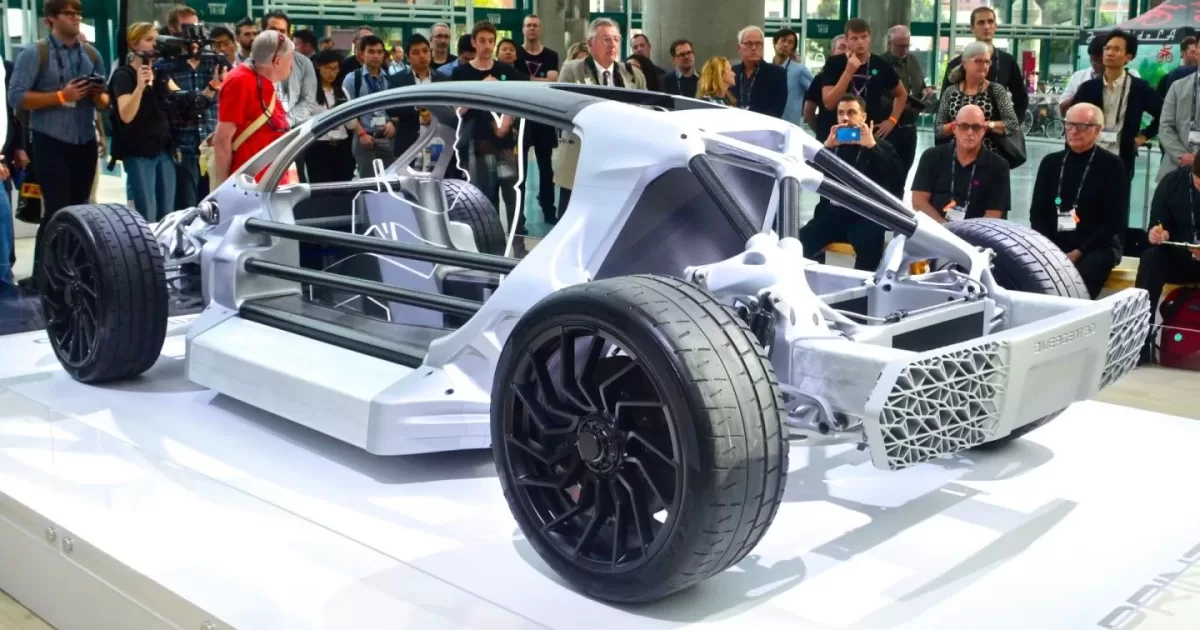

Concept Cars

3D printing pushes the boundaries of automotive innovation through building eye-catching concept cars. Designers have tremendous freedom to experiment with shapes and structures using 3D printing. Concept vehicles highlight styling, technology, and vision of the future. Automakers use the technology to create concepts with moving parts, intricate designs, and large-scale components. Concept cars bring 3D printing to the limits with bigger build volumes and multi-material printing.

In summary, 3D printing delivers game-changing advantages in prototyping, tooling, mass customization, spare parts, and concept cars. As the capabilities of the technology expand, its applications in the automotive industry will continue to grow. 3D printing is accelerating innovation in automotive design and manufacturing workflows. It provides flexibility and solutions not possible with conventional methods. The future of the automotive industry will undoubtedly be shaped by 3D printing technology.