When selecting a 3D printing process, choosing the optimal one is crucial. This article provides an overview of common 3D printing technologies and their key attributes to help you identify the best fit for your product.

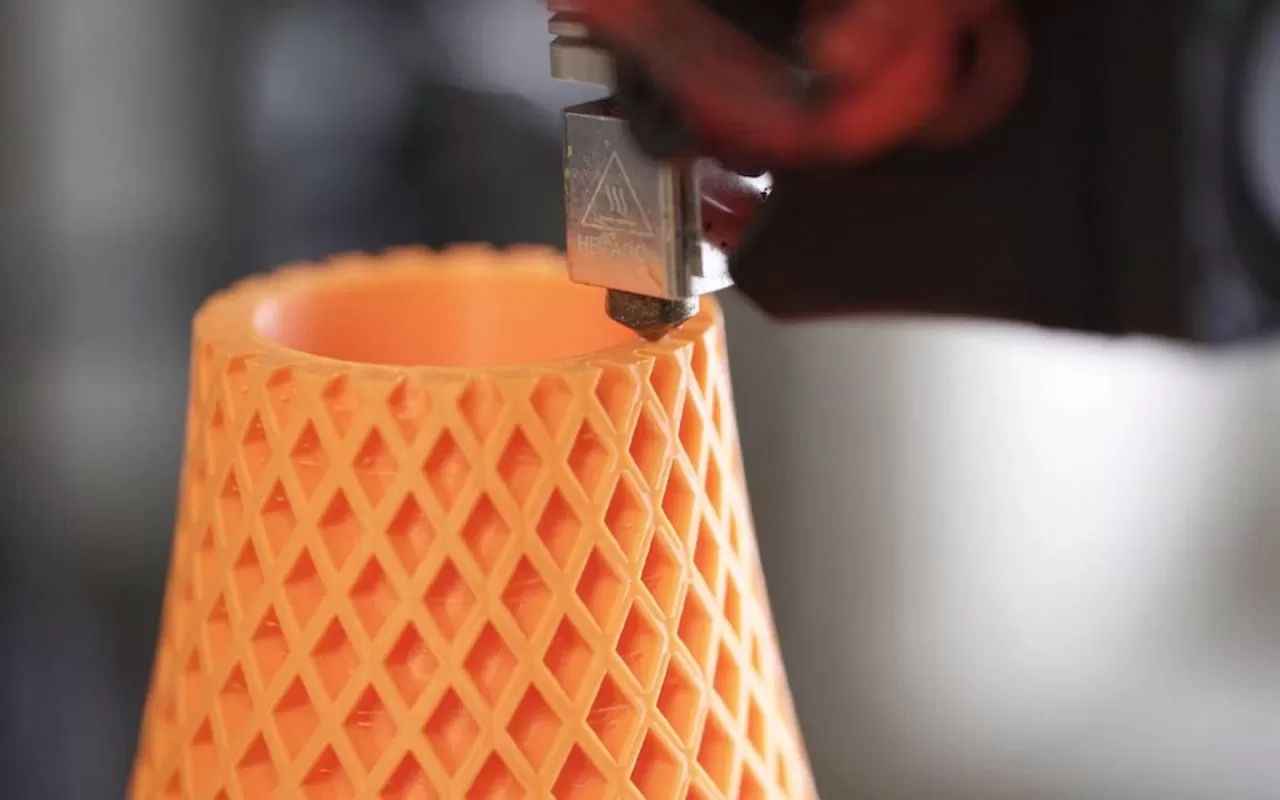

Fused Deposition Modeling (FDM)

FDM is a material extrusion process that builds parts layer by layer via an extrusion nozzle. It offers fast print speeds suitable for prototypes. Commonly used materials include ABS, PLA, nylon and ULTEMTM. Some advantages are quick turnaround, functional prototyping and a wide color range.

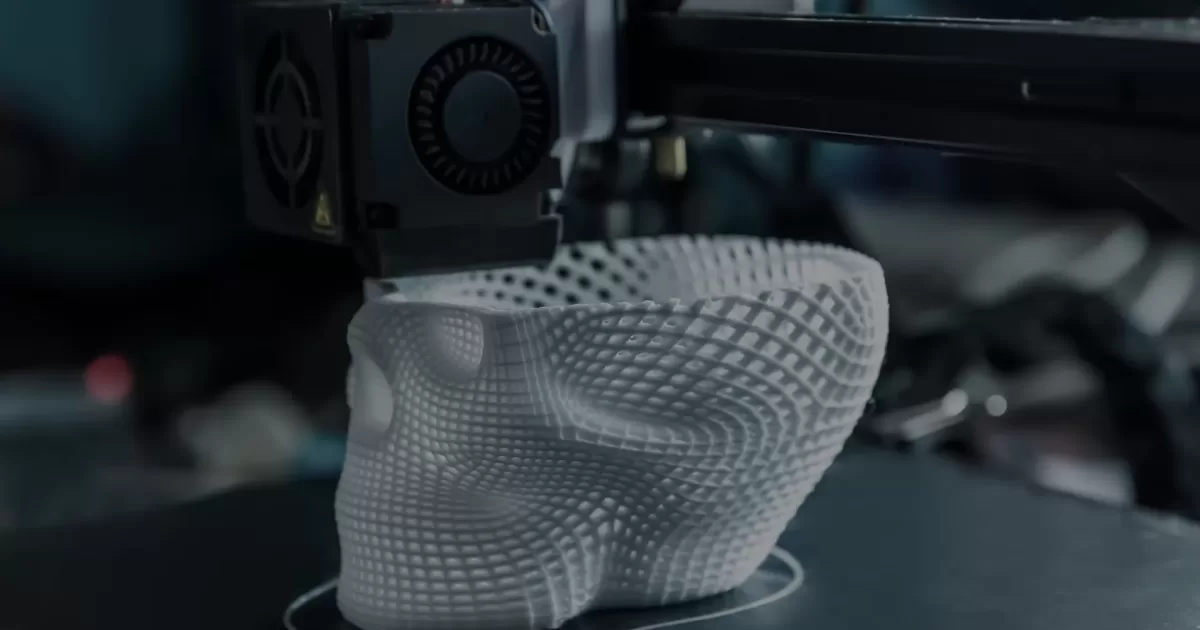

Stereolithography (SLA)

SLA cures liquid photopolymer resin into parts using a precise laser. It produces highly accurate and detailed parts ideal for medical or complex geometries. Post-curing achieves a smooth finish. Common resins include GP Plus, Taurus and EvoLVe.

Polyjet

Similar to SLA but uses lower heat to cure multi-materials like VeroClear and VeroGrey. Parts are fully cured after each cross-section, enabling highly complex multi-colored models.

Selective Laser Sintering (SLS)

SLS fuses powdered plastic particles with a laser. Self-supporting capabilities are ideal for intracacies like pipes. Costs can reduce up to 25% versus other methods. Popular materials include nylon, PA12, TPU and glass-filled nylon.

Multi Jet Fusion (MJF)

An HP technology that trades speed for more consistent properties than SLS. Ten times faster by heating full layers simultaneously. Commonly uses PA12 and glass-filled PA12.

Silicone 3D Printing

A new technology providing true elastomer parts with tunable shore hardness. Biocompatible ACEO GP materials expand design possibilities.

In conclusion, evaluate your needs like precision, speed, materials and certification to determine the optimal 3D printing solution for your unique product requirements. Contact us to discuss the best option.