3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering or adding material in a controlled manner. It allows the creation of complex and customized shapes that would be difficult or impossible to achieve using traditional manufacturing methods.

The basic principle of 3D printing involves converting a digital model into a physical object by building it layer by layer. The process typically involves the following steps:

- Designing the Model: The first step is to create a digital 3D model of the object you want to print. This can be done using computer-aided design (CAD) software or by scanning an existing object using a 3D scanner.

- Slicing: The 3D model is sliced into multiple thin horizontal layers using specialized software. Each layer is a cross-section of the final object.

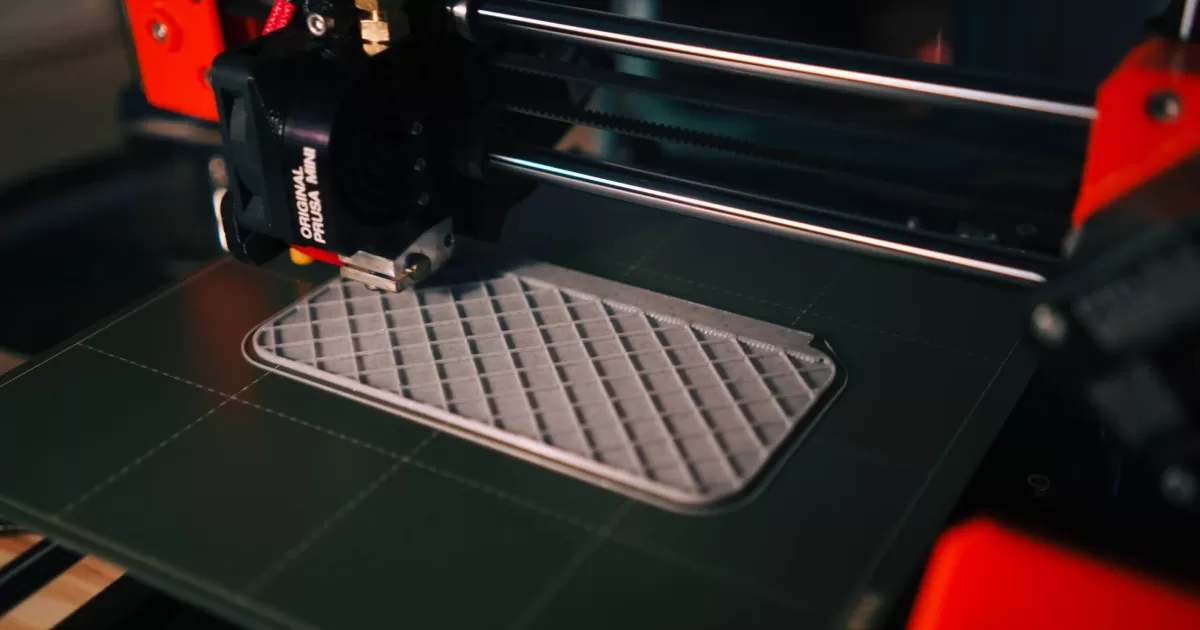

- Printing: The sliced model is sent to the 3D printer, which follows the instructions to build the object layer by layer. Various 3D printing technologies exist, such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and others. The specific technology determines the materials, process, and level of detail that can be achieved.

- Post-Processing: After printing, the object may require some post-processing, such as removing support structures, sanding, polishing, or painting, depending on the desired finish and application.

3D printing has gained popularity due to its versatility and numerous applications across various industries. Some of the key advantages of 3D printing technology are:

- Design Flexibility: 3D printing allows for intricate designs and complex geometries that are challenging to produce with traditional manufacturing methods. It enables customization and rapid prototyping.

- Reduced Waste: Unlike subtractive manufacturing processes where excess material is removed, 3D printing is an additive process, which can reduce material waste significantly.

- Shorter Lead Times: 3D printing eliminates the need for tooling or molds, enabling faster production cycles and reducing lead times for manufacturing.

- Cost-Effective: For low-volume production or one-off custom parts, 3D printing can be cost-effective compared to traditional manufacturing methods.

- Accessibility: 3D printers are becoming more affordable and accessible, allowing individuals, hobbyists, and small businesses to explore and experiment with the technology.

- Medical and Healthcare Applications: 3D printing has revolutionized healthcare by enabling the production of patient-specific medical implants, prosthetics, anatomical models for surgical planning, and drug delivery systems.

- Aerospace, Automotive, and Industrial Applications: 3D printing is used in these industries for rapid prototyping, tooling, lightweight component production, and supply chain optimization.

It's important to note that 3D printing technology continues to evolve rapidly, with advancements in materials, printing processes, and applications.