Introduction

Explore the possibilities of achieving injection molded-like quality with your 3D printed parts through the innovative technique of vapour smoothing. While injection molding offers excellent part quality, it comes with drawbacks such as long lead times and high costs. In this article, we delve into the advantages of vapour smoothing as a post-processing option that can deliver smooth, high-quality parts even in low volumes. Discover how this technique can revolutionize your manufacturing process from proof of concept to final production.

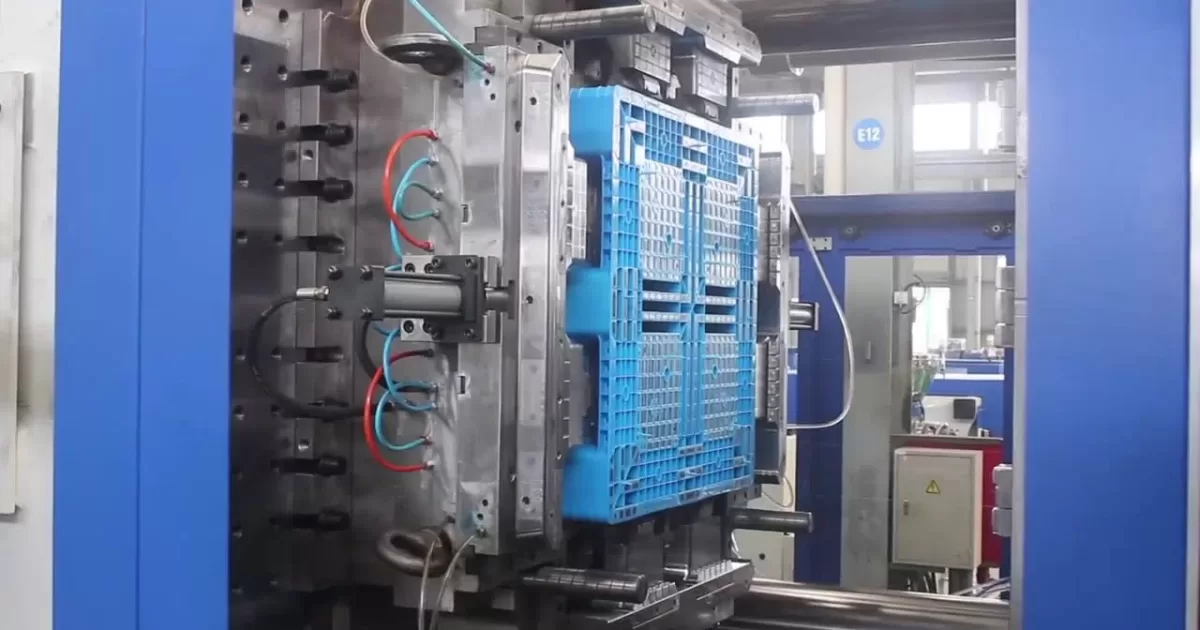

Pros and Cons of Injection Molding

Learn about the benefits and limitations of injection molding as a plastic forming technique. Understand its ability to produce high-quality products with tight tolerances and its flexibility for mass production. However, consider the drawbacks such as long lead times and high initial costs, including expensive tooling requirements. Explore the challenges of small production runs and the commitment involved in ordering large quantities.

Introducing Vapour Smoothing

Discover vapour smoothing as a cost-effective and efficient method for manufacturing smooth parts, even in low volumes. Understand how this post-processing technique utilizes an industry-safe solvent to smooth 3D printed parts, transforming them into functional end-use components. Learn how vapour smoothing eliminates visible layer lines and evens out the surface of the part, enhancing its overall quality.

The Vapour Smoothing Process

Gain insights into the vapour smoothing process and its three main cycles: processing, curing, and drying. Understand how the parts are loaded into the process chamber and treated with vapour BlastX, which reflows the boundary layer and improves surface finish. Learn how the parts are solidified, ensuring consistent and optimal processing conditions for superior results. Experience the benefits of the predetermined parameters that adjust temperature and pressure within the chamber.

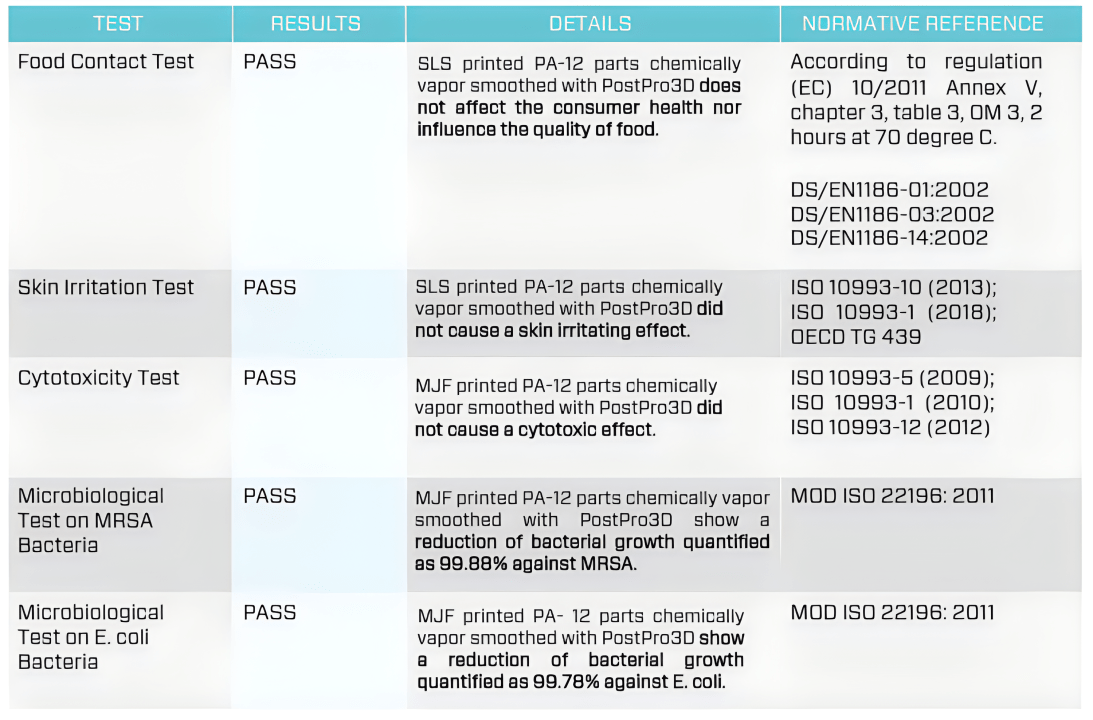

Advantages of Vapour Smoothing

Explore the unique advantages of vapour smoothing. Unlike other methods limited to specific materials, discover how V13D's vapour smoothing process works well with a wide range of thermoplastic technologies, including FDM, FFF, SLS, MJF, SAF, HSS, and more. Understand how it significantly decreases surface roughness and improves mechanical properties. Learn about the safety and regulatory compliance of V13D's vapour smoothing process, ensuring cured and dry parts ready for use.

Unlocking Smooth, End-Use Parts

Realize the potential of vapour smoothing as a post-processing option to achieve shiny, smooth parts with excellent surface finish. Embrace the versatility of this technique, applicable to various additive manufacturing processes. Contact us today to learn more about our industrial solutions and discover how vapour smoothing can elevate the quality of your 3D printed parts.

Conclusion

By leveraging the power of vapour smoothing, manufacturers can attain injection molded-like quality in their 3D printed parts. This innovative post-processing technique offers a cost-effective and efficient alternative, enabling the production of smooth, functional end-use components. Embrace the possibilities of vapour smoothing and witness the transformation of your prototyping and production processes into a realm of enhanced quality and aesthetics.